Getting Started with Siemens Industrial Automation

Starting your Industrial Automation career with Siemens can be a little confusing as Siemens has a vast range of products for hardware and software when it comes to Industrial Automation.

This article will help you understand the Siemens product range and selection of the hardware as per your application along with its compatible engineering software.

This article is beneficial for those also who are switching their carrier from different systems like Rockwell, Schneider, ABB, etc… or just want to get their hands on Siemens systems.

Siemens Industrial Automation

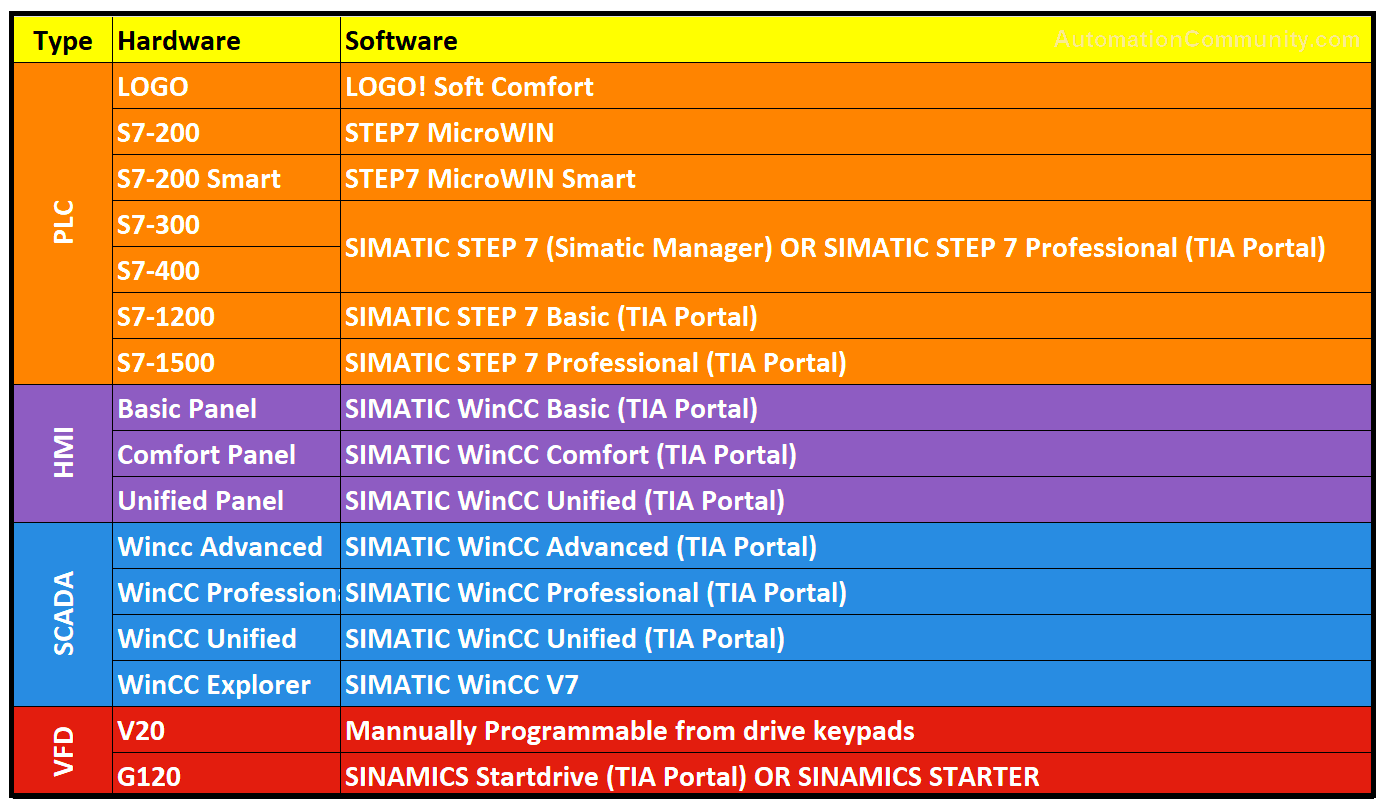

Please go through below table details. It contains the general series of PLC, HMI, SCADA, and VFDs which are mostly used in General Purpose Processes and/or Machine applications.

Please note that the portfolio of hardware and software from Siemens goes beyond this list as it also has multiple ranges of products within the series itself e.g. If we take S7-1500 Series from the below table, Siemens has S7-1500 as a general-purpose PLC, S7-1500F which is a Safety or Failsafe PLC specifically designed for critical application where safety is considered as a major design factor, S7-1500R/H which is a redundant PLC specifically design for application which requires high availability of PLC Controllers, S7-1500T is a technology PLC specifically designed for motion control applications. Similarly other series also have different products within their series for specific applications.

For VFDs, we have taken V20 and G120 (Majorly used VFDs in Process Industries by the System Integrators)

We will take a brief look into the details one by one.

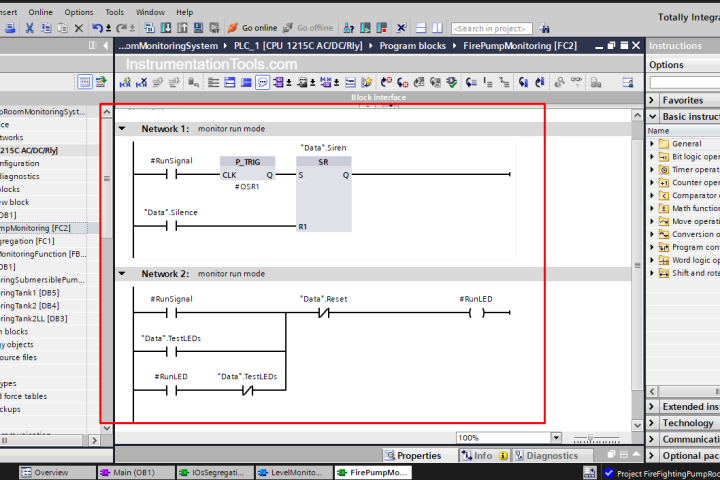

You can also try our free course on the Siemens TIA portal.

Programmable Logic Controllers (PLC)

Siemens offers different types of PLCs which we can choose as per our application requirements. The main models are mentioned below.

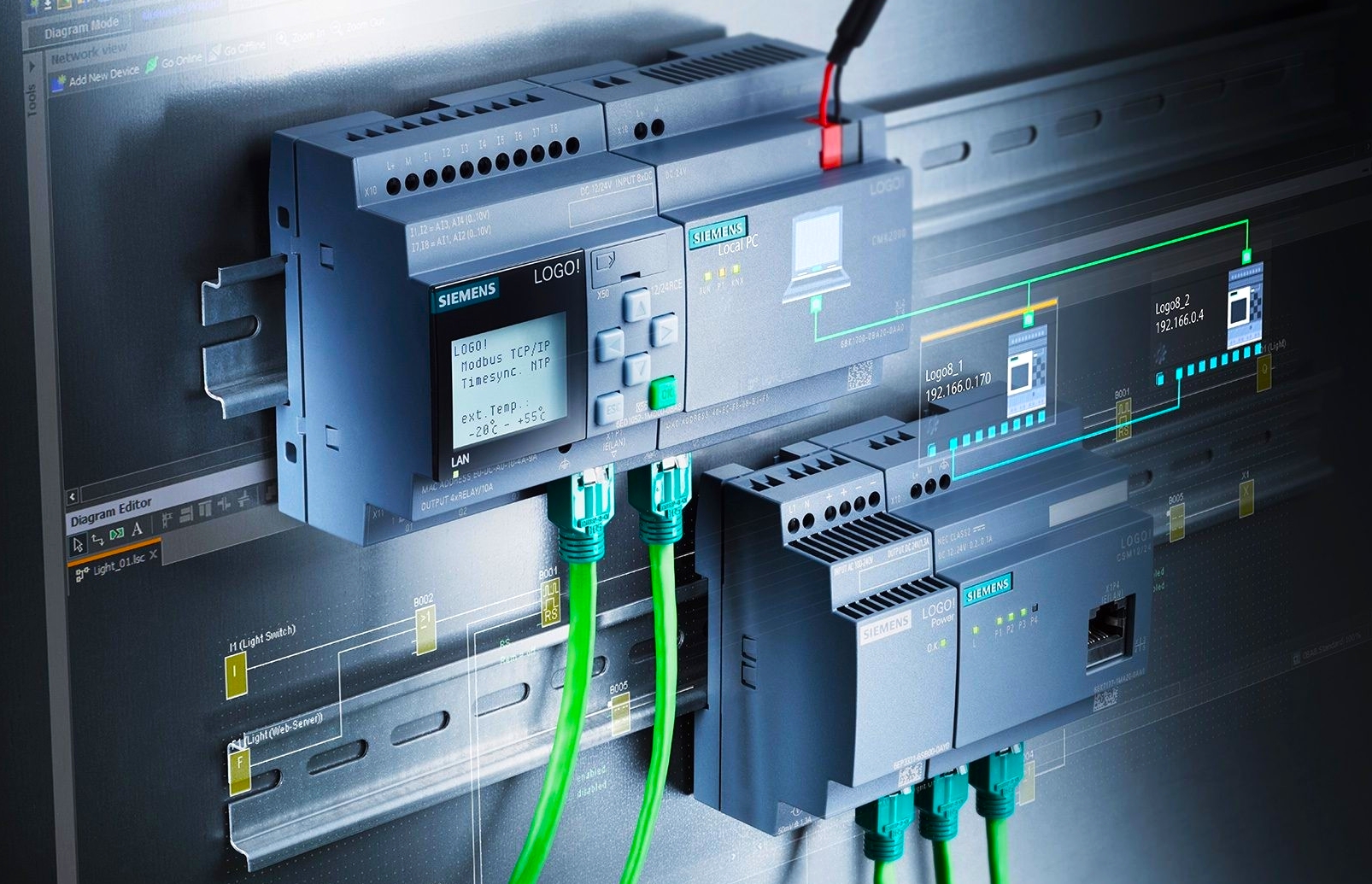

Logo PLC

Logo PLC is an ideal controller for simple automation tasks in industry and building services. The modular design of LOGO PLC makes it consistently flexible. A wide range of modules allows you to create Configurations to meet your needs.

You can program a Logo PLC with LOGO! Soft Comfort. This software also has a demo version that allows users to create and simulate a program.

Please note that you will need a licensed version to download/upload or go online with an actual PLC

S7-200 PLC

Then we have S7-200 and S7-200 Smart PLCs. Which are generally used in small process/machine applications. S7-200 has serial communication and can be connected with software via a specific PC-PPI cable from Siemens.

S7-200 Smart comes with onboard Ethernet Connectivity and can be accessed via any Ethernet cable. It can be programmed with STEP7 MicroWIN and STEP7 MicroWIN Smart respectively.

Step7 MicroWIN is free software and it is available on the Siemens website. S7 MicroWIN Smart can be ordered via any Siemens local sales partner.

S7-200 PLC also supports onboard serial communication with third-party devices via RS-485 or RS-232.

S7-300 PLC

S7-300 PLCs are suitable for medium-sized applications. S7-300 can be programmed using the Simatic Manager. Standalone S7-300 PLC Controller can also be programmed with SIMATIC STEP 7 Professional (TIA Portal).

S7-300 PLC Support extended racks which can be connected to the main controller via PROFIBUS or PROFINET communication protocol. The S7-300 PLC range is available in the market for more than 2.5 decades and to date.

The S7-300 PLC is one of the best controllers that Siemens has had but In order to make future-proof systems Siemens is planning to discontinue this S7-300 Series by replacing it with the existing S7-1500 PLC Series.

Check the information on the product lifecycle – from Siemens

The SIMATIC S7-300/ET 200M system families are part of our established product range and will definitely be available until 2023. Upon publication of a product phase-out announcement, the respective product will be available as a spare part for a period of ten more years until 2033.

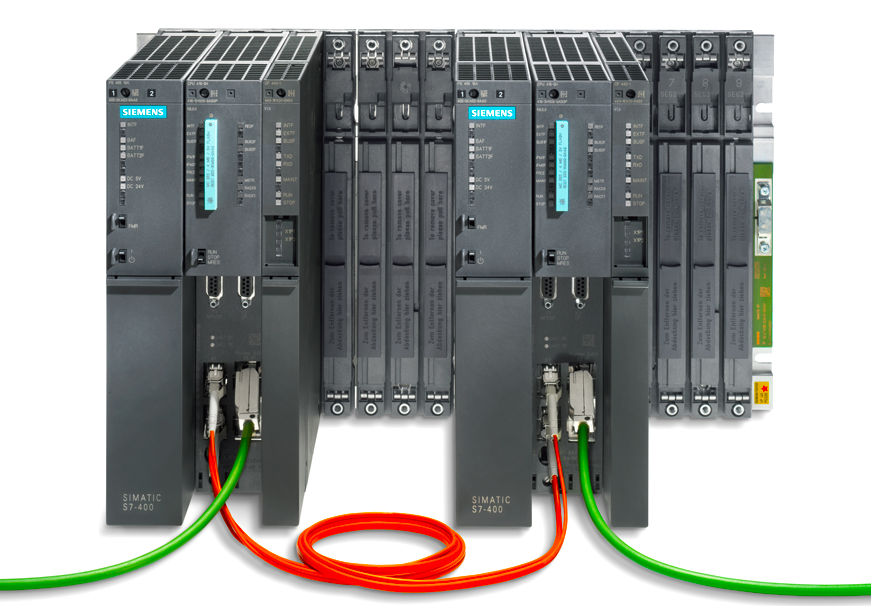

S7-400 PLC

For large-scale applications, we have the S7-400 PLC. It is a powerful PLC from Siemens that has been designed for system solutions in the fields of manufacturing and process automation.

The S7-400 process controller is ideal for data-intensive tasks that are especially typical for the process industry. It supports complex network configurations with multiple communication protocols.

S7-410 Series is widely used in DCS systems (PCS7 from Siemens). S7-400H (Redundant PLC System) is a go-to solution for process industries where high availability is required.

Please note that Only Standalone S7-400 PLC can be programmed with Both TIA Portal and Simatic Manager Software. S7-400H (Redundant System) can only be configured and programmed with Simatic Manager

S7-1200 PLC

S7-1200 is a compact PLC from Siemens that can be programmed with SIMATIC STEP 7 Basic (TIA Portal) Software. It supports Modbus TCP/IP Communication by default via an onboard Ethernet port.

S7-1200 can be used in small to medium-scale industrial applications. The best part is, for a small-scale application it can be clubbed in a single program with TIA Portal when using WinCC Advance SCADA or Comfort/Basic HMI.

This will reduce the development time as the TIA portal offers dynamic configuration for tagging via symbolic access for TAGs. S7-1200 PLC also offers an integrated web server and comes with OPC compatibility.

S7-1500 PLC

S7-1500 is a high-end controller from Siemens. There are multiple PLCs in S7-1500 PLCs having different memory, IO handling capacity, and communication ports. The S7-1500 also has a built-in display for basic information and diagnostics.

S7-1500 PLCs are widely used in medium-to-large process automation and medium-to-complex machine automation. Different PLCs from the S7-1500 series are also available as stated in the example in the introduction.

S7-1500 PLC can be programmed with SIMATIC STEP 7 Professional (TIA Portal) software. With S7-1500 PLC we can use most of the features that TIA Portal software has for a PLC. The S7-1500 has all the features that are stated above for S7-1200 PLC and in addition, there are much more.

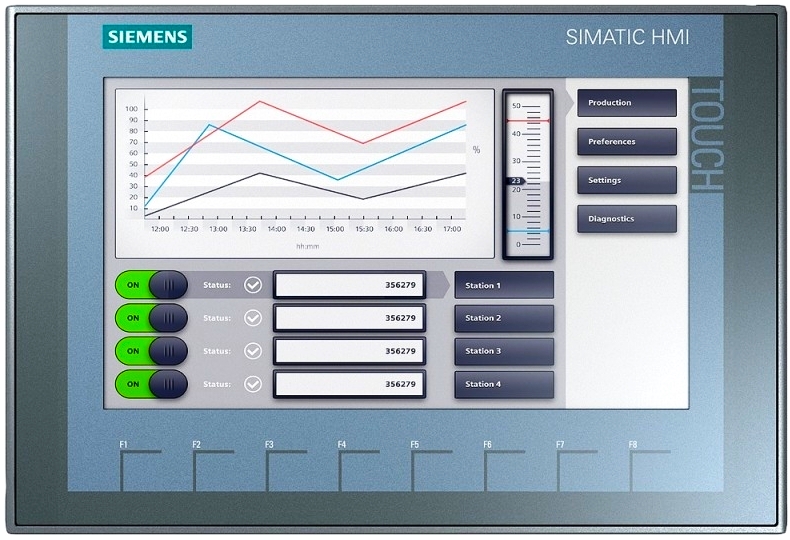

Human Machine Interface (HMI)

Siemens offers three versions of the HMI models. They are mentioned here.

Basic HMI Panel

A basic HMI Panel is used in small machine/process applications as it has limited features compared to other Siemens HMIs.

The basic HMI Panel serves the purpose of HMI for basic application. It can be designed and configured from SIMATIC WinCC Basic (TIA Portal).

Comfort HMI Panel

Comfort HMIs has more features compared to basic HMIs, it has more available tags, and data archiving is possible for trends and Alarm logging.

Comfort HMI has a Symbol Library for a majority of the industrial used equipment. It supports popup windows (picture in picture mode) for faceplates of equipment like valves, pumps, etc

Comfort HMI also supports library support for the standardization of processes or machines, and the same library function can also be shared with WinCC Advanced SCADA in a single TIA Portal project

Unified HMI Panel

As stated by Siemens this is “The next generation of Comfort Panels”. It works on web and edge technologies combined with open interfaces.

The Unified HMI Panel allows the installation of apps and simplifies scaling as it uses vector-based visualization (responsive graphics).

The Unified HMI Panel has features like integrated remote access and direct connectivity to RFID readers. It can be designed with SIMATIC WinCC Unified (TIA Portal)

Supervisory Control and data acquisition (SCADA)

Siemens provides SCADA software packages with different versions such as WinCC Advanced, Professional, and V7.

Also, check our course on WinCC – Training Videos

WinCC Advanced SCADA

WinCC Advanced SCADA from Siemens is designed for small to medium-scale industrial applications and it can be programmed with SIMATIC WinCC Advanced (TIA Portal) which allows the development of an integrated project along with other TIA Based PLCs, HMIs, and VFDs. It has basic features of a SCADA System like data logging, Trends, Alarms, and Reports.

WinCC Advanced SCADA also supports the use of VB Scripting. This SCADA can be operated as a standalone system only. Separate Licenses are available to Engineering and Runtime.

A License for data logging is also needed if one is planning to archive data for alarms and trends.

WinCC Professional SCADA

WinCC Professional is more feature full SCADA from Siemens. It has all the features of WinCC Advanced and there are much more in addition to that. It supports VB as well as C Scripting on object-level configuration.

It also has a provision to design a server client-based system for monitoring from different plant locations. It can be designed and programmed with SIMATIC WinCC Professional (TIA Portal).

WinCC V7 SCADA

WinCC V7 is a high-performance SCADA Solution from Siemens that is used in large process/manufacturing plants. It can be configured and designed with WinCC Explorer.

This SCADA system supports complex architectures like redundant SCADA servers with multiple clients. It is also used in PCS7 System as a DCS system.

It is an innovative, scalable process visualization system with numerous functions for monitoring automated processes.

Variable Frequency Drives (VFD)

The main models of Siemens SINAMICS ac drives are V20 and G120.

V20 VFD

Sinamics V20 VFD is a compact and cost-effective AC drive from Siemens which is generally used in basic processes and machines for pumping, compressing, and conveyor application.

Sinamics V20 VFD has basic features and it also supports Serial communication. Sinamics V20 VFD can be programmed with a built-in display and keypad. V20 VFD can also be programmed using its web server by adding smart access module.

Siemens Sinamics V20 VFD is available with a power range from 0.12 kW to 30 kW.

G120 VFD

Sinamics G120 VFD is a more advanced drive from Siemens. It comes with more communication protocols available on board or with an expansion module.

Sinamics G120 VFD can be programmed with Sinamics STARTER or STARTDRIVE (TIA Portal). Communication with PLC can be easy as it can be easily integrated into a single TIA Project.

This series of VFDs are available in three voltage variants for connection to 200 V, 400 V, and 690 V networks. In addition, the SINAMICS G120 features a comprehensive machine safety package that can be commissioned by STARTDRIVE.

Siemens Sinamics G120 VFD is available as a compact drive and it is also available as a separate power module and control unit so that we can select as per our requirements.

The Sinamics G120 VFD is available with a power range from 0.55 to 250 kW

Other than this there are many different drive series available from Siemens like V70, V90, G110, G115, G130, G150, G180, S120, S150, S210, S220, and Micro Master Drives for industry Specific applications and servo applications.

Conclusion

Apart from the above-listed product range Siemens also has their range of Safety PLCs, Technology PLCs for Motion Control Applications, PCS7 for the Distributed Control System (DCS), and Simotion Controller specifically designed for complex and high-performing machine applications. And this list of products goes on and on.

Here we have tried to give a brief introduction just to get you started with Siemens Industrial Automation Systems.

You can download TIA Portal from the Siemens website, and it is available for free for a trial period. Familiarize yourself with the TIA Portal interface, once you have installed the software you can access help documentation from within the software and also on the internet to help you get started.

Siemens has also curated learning and training documents for initial training which you can find via this link

Please refer attached document “see-guide-learn-training-guide-en.pdf” to get yourself familiar with the training program.

All Image Source – Siemens Website

Reference – Siemens Website and Technical Manuals

Read Next:

Comments

1

Really good article. Nicely covered