Top Tips and Best Practices for DCS Maintenance

In this article, you will learn the top tips and best practices for DCS maintenance (Distributed Control Systems).

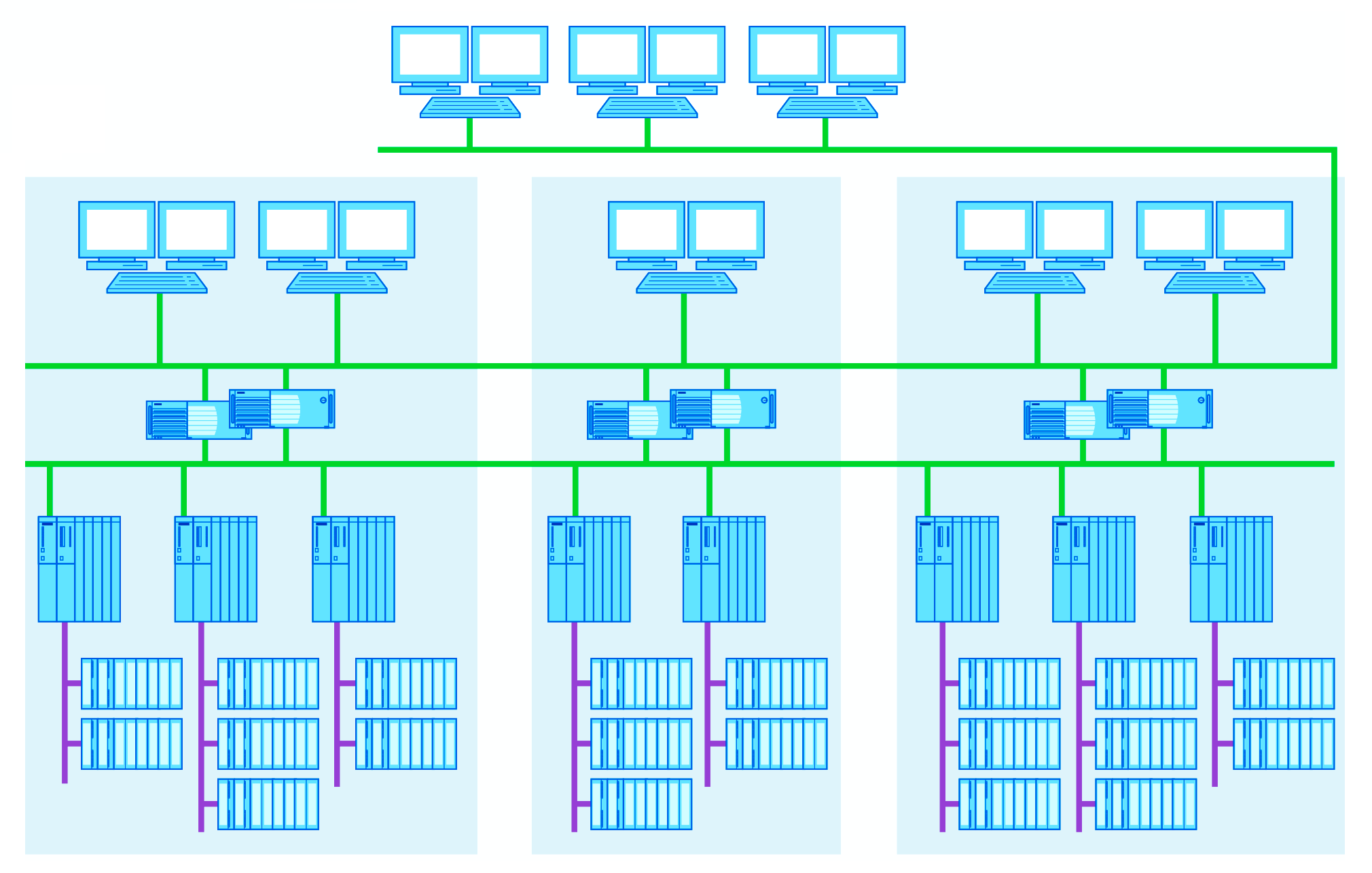

Distributed Control System (DCS)

Regular maintenance of a Distributed Control System (DCS) is critical to ensure that it operates as intended, providing efficient and reliable control of industrial processes. Without regular maintenance, a DCS system can experience various problems such as equipment failure, system downtime, and data loss. These issues can lead to decreased efficiency, increased downtime, and potential safety hazards.

The maintenance and upkeep of a DCS system typically include regular inspections, software updates, backup and recovery, preventive maintenance, training, and cybersecurity measures. Additionally, it is important to have detailed documentation of the system, regularly test and monitor the system’s performance, and have a stock of spare parts on hand.

Best Practices for DCS Maintenance

Some best practices for DCS maintenance and upkeep include:

- Regular Inspections: Regularly inspecting the DCS system and its components can help to identify potential issues before they become major problems. This includes inspecting the control panels, wiring, and other components for signs of wear or damage.

- Software updates: Keeping the DCS software updated can help to prevent security vulnerabilities, improve performance and add new features. It is essential to have a plan in place to update the software in a controlled manner, testing it before implementing it in the production environment.

- Backup and Recovery: Having a robust backup and recovery plan in place can help to minimize downtime and data loss in case of system failure. This includes regularly backing up the system configuration and process data and testing the recovery process.

- Preventive Maintenance: Preventive maintenance can help to extend the life of the DCS system and reduce downtime. This includes regular cleaning, tightening connections, lubricating moving parts, and checking for proper alignment and calibration.

- Redundancy: Implementing redundancy in the DCS system can help to ensure that the system is still able to function in case of failure. This can include having redundant controllers, sensors, and other critical components, as well as implementing redundant communication networks.

- Performance monitoring: Regularly monitoring the performance of the DCS system can help to identify issues and inefficiencies. This includes monitoring system availability, response time, and data integrity.

- Training: Providing training to operators and maintenance personnel can help to ensure that the system is operated and maintained correctly. This includes training on how to properly operate the system, troubleshoot issues, and perform preventive maintenance tasks.

- Documentation: Having detailed documentation of the DCS system, including system architecture, control strategies, and configuration, can help to ensure that the system is operated and maintained correctly. This documentation should be kept up-to-date and accessible to all relevant personnel.

- Regular testing: Regularly testing the DCS system and its components can help to ensure that it is operating correctly and that all control loops are functioning as expected. This includes testing in a simulated environment and in the actual process.

- Spare parts: Having a stock of spare parts on hand can help to minimize downtime in case of a failure. This includes critical components such as controllers, sensors, and actuators.

- Vendor support: It is important to have a good working relationship with the DCS vendor and to have a support contract in place. This can provide access to technical support, software updates and upgrades, and training.

- Auditing and compliance: It is important to ensure that the DCS system is in compliance with relevant industry standards and regulations. Regular auditing and compliance checks can help to identify any issues and ensure that the system is operating within the required standards.

- Cybersecurity: It is essential to have a cybersecurity plan in place to protect the system from cyber-attacks. This includes regular security audits, implementing firewalls, intrusion detection and prevention systems, and ensuring that software and firmware are updated with the latest security patches.

- Remote monitoring and control: Utilizing remote monitoring and control capabilities can help to minimize downtime by allowing for remote troubleshooting and maintenance. This includes monitoring system status, diagnostics, and alarms, and making adjustments to the system remotely.

- Life cycle management: Implementing a life cycle management plan for the DCS system can help to ensure that the system is replaced or upgraded before it reaches the end of its useful life. This can help to prevent system failures and ensure that the system is always operating at its optimal level.

- Continual improvement: The maintenance and upkeep of a DCS system should not be viewed as a one-time task, but rather as a continuous process of improvement. Regular review and evaluation of the system’s performance and making necessary updates and upgrades can ensure that the system is always operating at its optimal level.

- Energy management: Implementing energy management practices can help to reduce the energy consumption of the DCS system, resulting in cost savings and reducing the environmental impact. This includes monitoring and optimizing the energy consumption of the system and implementing power management strategies.

- Scalability: The DCS system should be designed to be scalable, so it can adapt to the changing needs of the process. This includes having the ability to add new control loops, sensors, and other components as needed, and having the flexibility to adapt to new process requirements.

- Environmental monitoring: Monitoring the environmental conditions such as temperature, humidity and vibration can help ensure that the DCS equipment is operating within its safe and optimal range. This can prevent equipment failure caused by extreme temperatures or vibration.

- Data management: Implementing a data management strategy can help to ensure that the DCS system is able to collect, store, and analyze large amounts of data. This includes implementing data archiving and backup and having the ability to access and analyze historical data.

Conclusion

Regular inspections, software updates, backup and recovery, preventive maintenance, training, and cybersecurity are some of the best practices that can help ensure the longevity and proper functioning of a DCS system. By implementing these practices, organizations can minimize downtime, improve efficiency and ensure the safety and reliability of their industrial processes.

Read Next: