Capacitance Level Transmitter – Pune Techtrol

Description

The Capacitance Level Transmitter is a compact device designed for continuous level measurement in both conductive and non-conductive liquids, suitable for use in open or pressurized tanks. This microcontroller-based device provides accurate and reliable level measurements.

Capacitance Level Transmitter

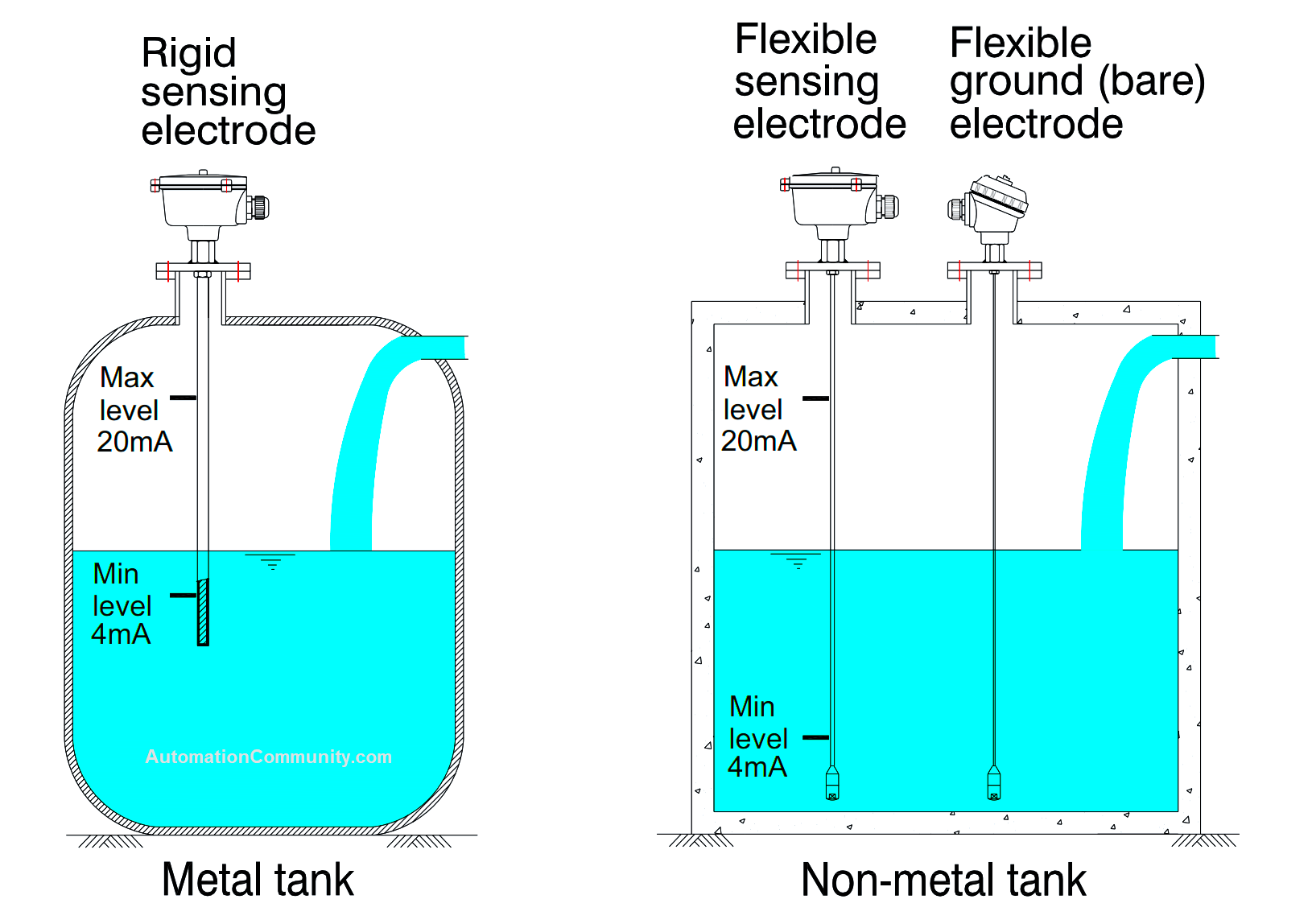

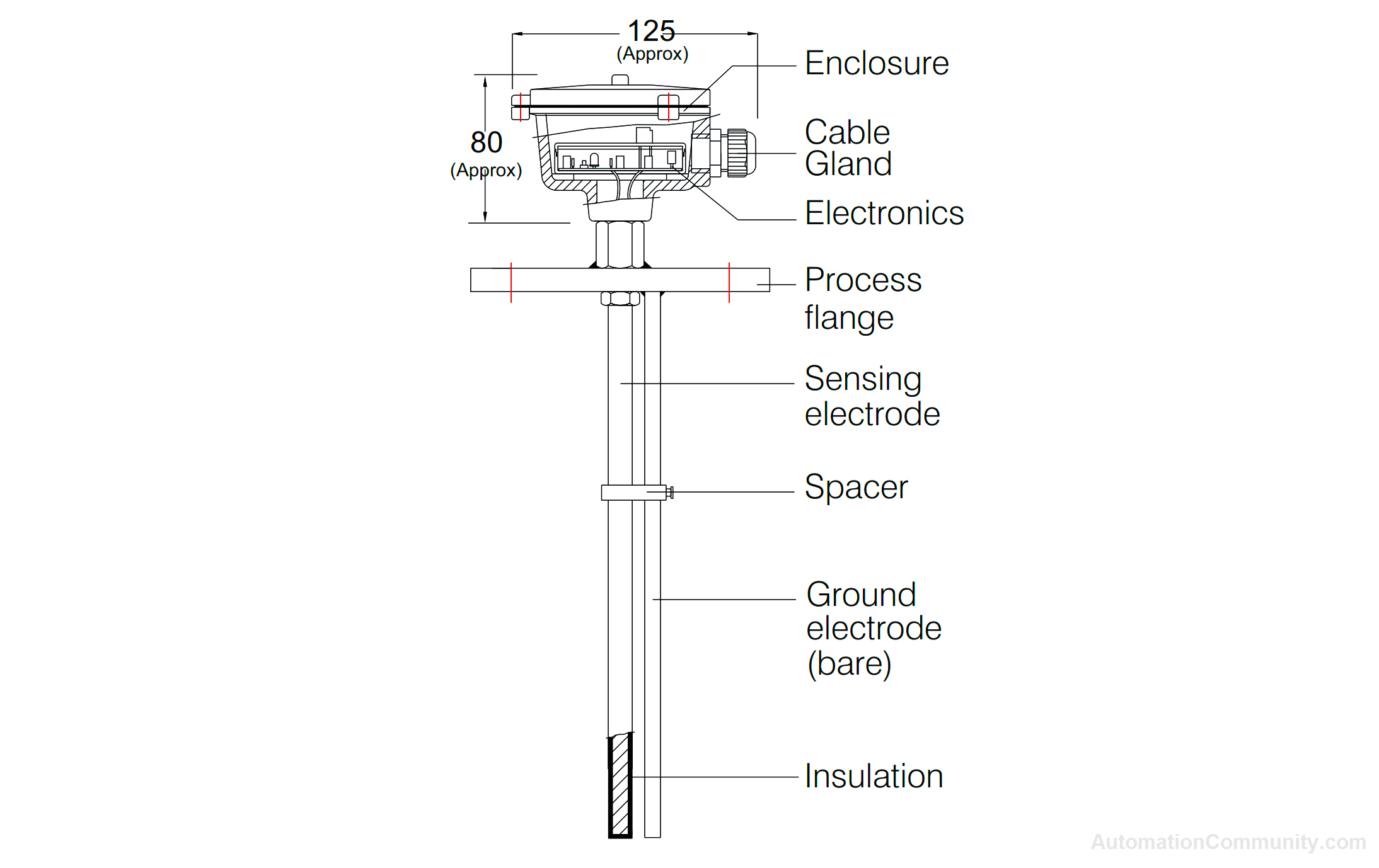

The Capacitance Level Transmitter operates through a sensing and grounding electrode, which is equipped with an integrated electronic system. The probe is top-mounted with either flanged or screwed process connections.

The change in liquid level causes the capacitance between the sensing and ground electrodes to vary, which is then converted into a 4-20 mA output signal.

Features:

- Microcontroller-based compact design

- 2-wire 4-20mA output (loop-powered)

- Push-button calibration for easy operation

- Suitable for measuring conductive and non-conductive liquids in open or pressurized tanks

- Various electrode constructions are available to handle corrosive, low conductive, and low dielectric media.

Installation of Capacitance Level Transmitter

- Install the transmitter vertically from the top.

- Select a suitable location for the probe on the tank where turbulence is minimum.

- The probe should be located such that the direct flow of material on the probe is avoided.

- Ensure that the process connection of the level transmitter matches those on the tank.

- The sensing electrode should be parallel to the reference electrode/tank wall.

- The electronics should be protected from direct sunlight in case of outdoor installation.

- During the installation of the flexible probe, insert it carefully inside the tank as rough handling may lead to damage to the probe and its insulation.

Capacitance Level Transmitter Specifications

- Enclosure: Cast Al, WP IP 66 or ABS, WP IP 65

- Conduit connection: Polyamide, PG 11

- Electrode type: Rigid – 500-1500mm, Flexible – 1500-5000mm

- Installation: Top

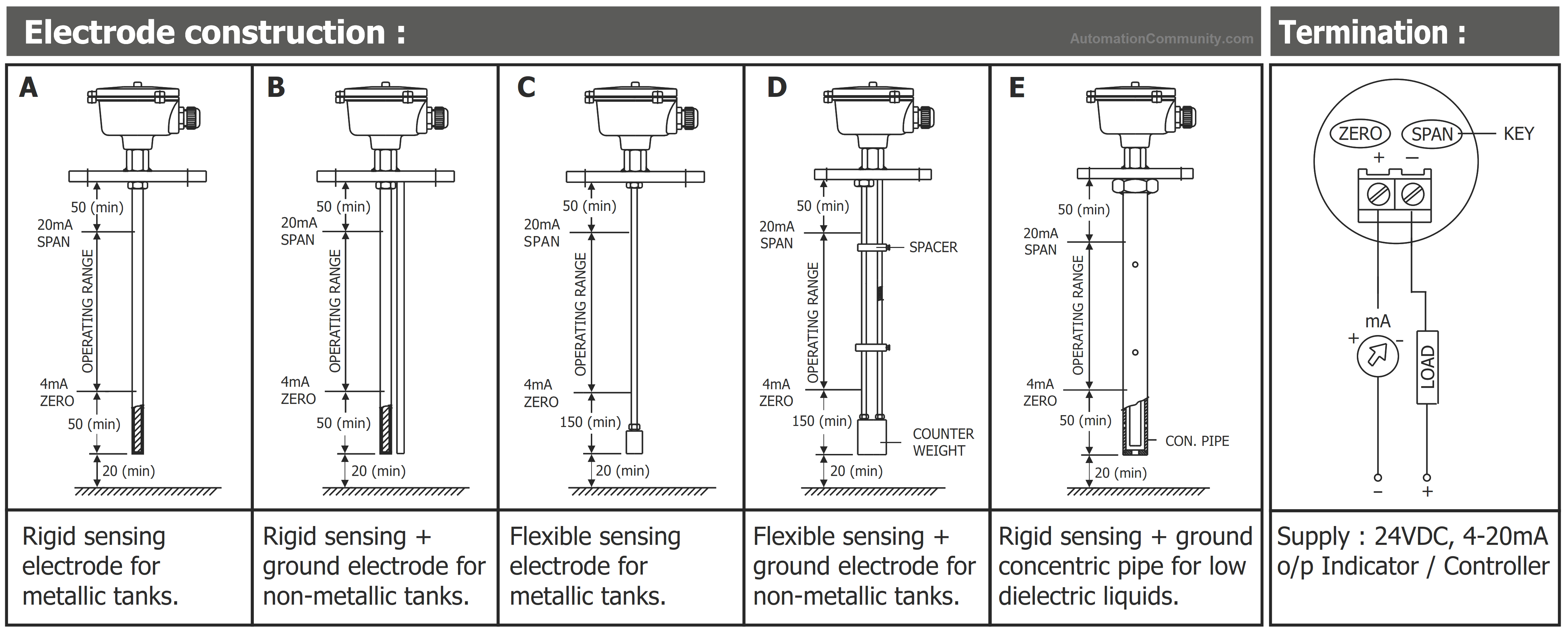

- Electrode construction: Rigid or Flexible sensing electrodes with rigid or flexible or concentric ground pipe electrodes

- Electrode material: SS304 or SS316

- Sensing electrode: PVDF lined

- Ground electrode: Bare or PVDF lined for corrosive applications

- Calibration: Zero & Span calibration through push-button keys

- Power supply: 24 VDC

- Output: 4-20 mA

- Wiring: 2 – wire

- Max load: 400 ohms at 24 VDC

- Capacitance range: 10 to 2000 pf

- Accuracy: ±2% of FSD

- Max temperature: 60°C

- Max pressure: 5 Kg/cm²

Calibration of Capacitance Level Transmitter

To calibrate a capacitance level transmitter at the site, the following below steps.

- Wire the terminals as indicated in the above Fig (right).

- Fill the tank to the minimum level corresponding to the output of 4mA.

- Press the “ZERO” key until the red LED is switched ON and then OFF. This will set the transmitter for 4mA output, which can be confirmed using a multimeter.

- Fill the tank to the maximum level corresponding to the output of 20mA.

- Press the “SPAN” key until the red LED is switched ON and then OFF. This will set the transmitter for 20mA output, which can be confirmed using a multimeter.

- The transmitter is now calibrated and can be used under the site operating conditions.

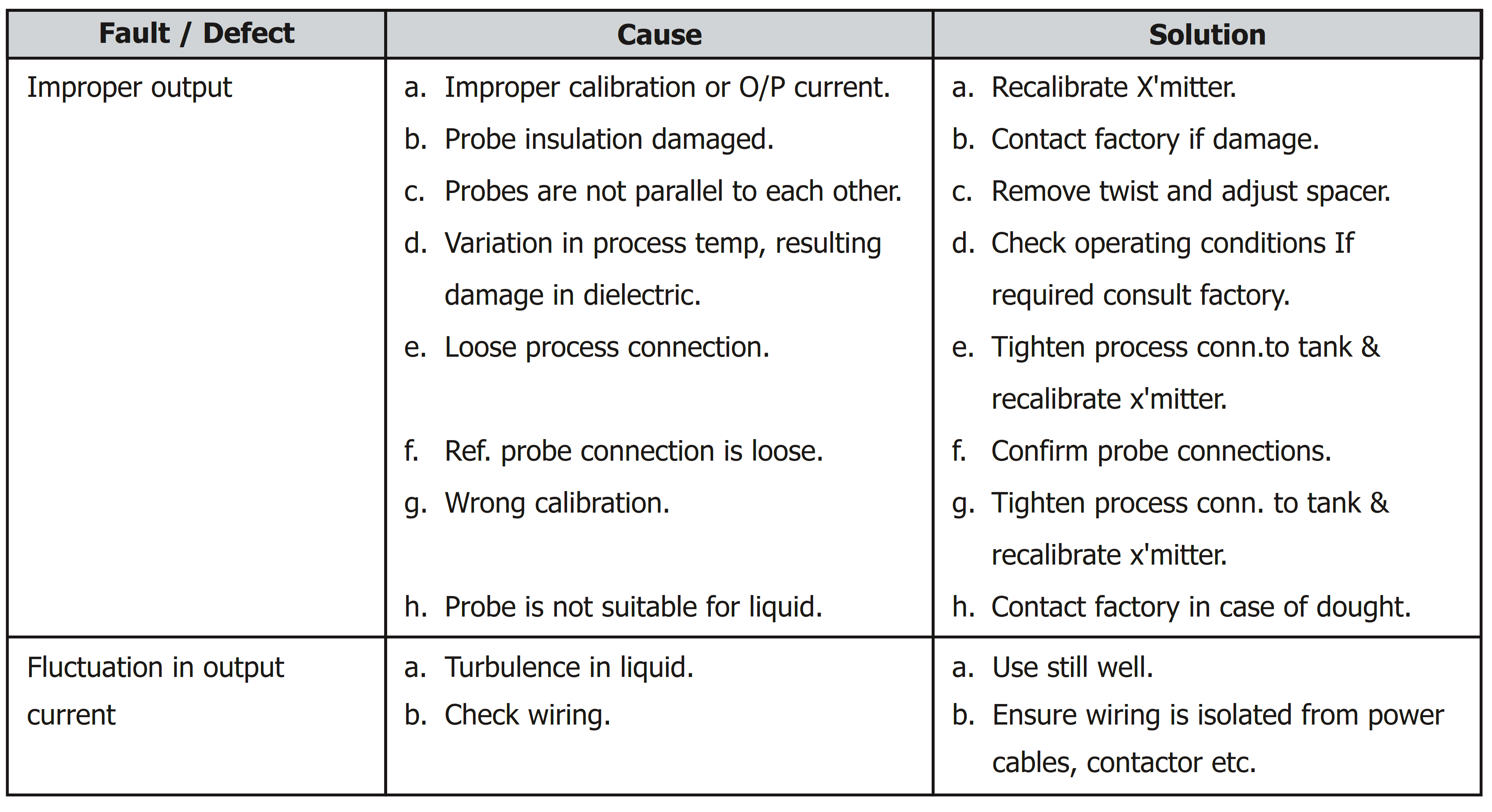

Troubleshooting of Capacitance Level Transmitter

Some of the common problems and solutions of Capacitance Level Transmitter.

Applications of Capacitance Level Transmitters

Some common applications of capacitance level transmitters include:

- Raw, sea, treated, demineralized, and purified water level measurement

- Coolant level measurement in automotive and industrial applications

- Transformer oil level measurement

- Milk and fruit juice level measurement in food and beverage processing

- Water storage tank level measurement

- Underground tank level measurement

- Fuel oil tank level measurement

- Water treatment plant level measurement

- Fire protection system level measurement

Location

Report abuse

Report abuse

Featured