Control Valve Problem Causes Repeated Plant Trips

In this article, you will learn the control valve problem that causes repeated plant trips and its root cause analysis.

Today in this article, we will learn one of the root cause analysis which was done for a control valve that got fully closed when the command to the control valve was near 65% in auto mode.

Control Valve Problem

A control valve (let the tag be 05-PRD-CV-A) was installed on the battery limit of process plant A. The control valve was used for controlling the flow of the product from process plant A to other process plants B in the downstream.

The process plant B in the downstream was totally dependent on the product from process plant A. The control valve was used as an Emergency Shutdown Device also. The purity of the product was highly important and whenever the purity was out of the specifications or say limit, the control valve closes. The line size was 24 inches. Also, the location of the control valve was on the 2nd floor above ground.

Process plant A was under shutdown for a week due to the breakdown of some mechanical equipment. After the plant startup, the purity of the product became normal after a few hours of running the plant. The final control valve 05-PRD-CV-A was given open command. The valve opened properly and after some time, the valve was kept in auto mode by the panel engineer.

For 14 hours, the plant ran without any issues. Then suddenly the final control valve 05-PRD-CV-A got fully closed. The panel operator saw that the command to the control valve was 65 % open as per the PID controller command. But the feedback of the control valve was 100 % closed.

Also, the upstream line pressure of the final control valve (05-PRD-CV-A) started increasing and the plant got trip. Due to product supply disruption to the downstream plant, the downstream process plant B also got tripped due to a low feed flow rate.

Observations of the Operation & Maintenance Team

When the final control valve 05-PRD-CV-A got fully closed, an alarm of 05-PRD-CV-A CLOSED INDICATION came on the DCS alarm page.

Also, the command vs feedback discrepancy alarm came on the alarm page. The panel engineer immediately saw that the command through the PID controller was 65 % open but the final control valve 05-PRD-CV-A is fully closed.

The panel engineer tried to change the command to 100 % open by taking the PID controller to manual mode from auto mode. But still, the final control valve 05-PRD-CV-A did not open.

Immediately, an Instrument Engineer went to see the final control valve 05-PRD-CV-A in the field. In the field, the instrument air tubing to the Air Filter Regulator was found detached. The fitting of the tubing was also in damaged condition.

A Fault Tree Analysis, as well as Root Cause Analysis, was done for this incident in which the instrument air tubing to the final control valve 05-PRD-CV-A got detached.

Let us see the detailed fault tree analysis of this incident.

Fault Tree Analysis

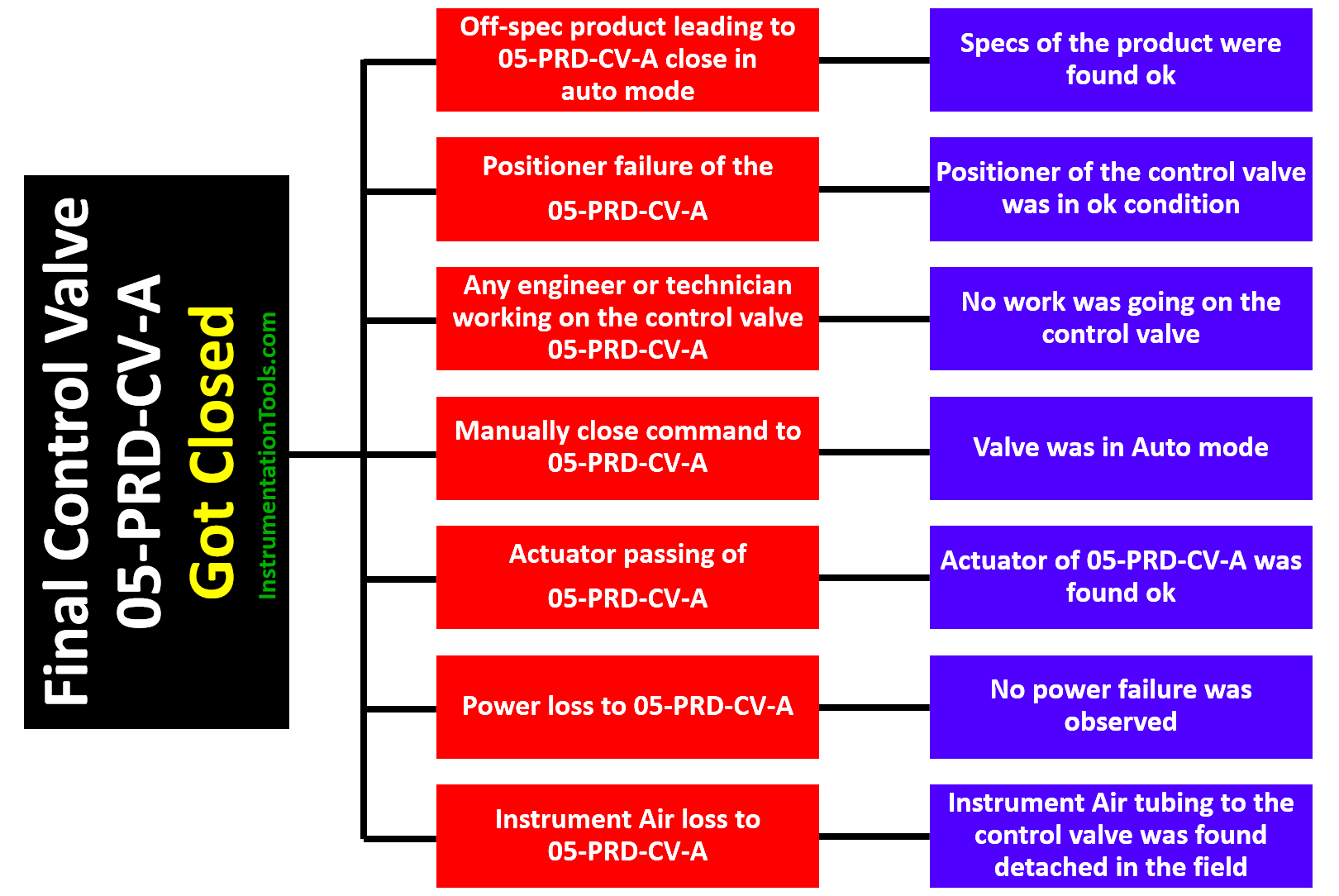

Fault tree analysis was made for the final control valve 05-PRD-CV-A which got fully closed and disrupted the multiple plant operations.

The fault tree analysis is shown below.

As seen from the above fault tree analysis, various causes were identified for the problem statement “the final control valve 05-PRD-CV-A which got fully closed and disrupted the multiple plant operations”.

Various reasons were taken into consideration for fault tree analysis:

- Off-spec product leading to 05-PRD-CV-A close in auto mode

- Positioner failure of the 05-PRD-CV-A

- Any engineer or technician working on the control valve 05-PRD-CV-A

- Manually close command to 05-PRD-CV-A

- Actuator passing of 05-PRD-CV-A

- Power loss to 05-PRD-CV-A

- Instrument Air loss to 05-PRD-CV-A

The final conclusion from the fault tree analysis was that the final control valve 05-PRD-CV-A got fully closed due to Instrument Air loss to the 05-PRD-CV-A.

Detailed root cause analysis was carried out for this incident.

Let us see what was the main cause of this instrument’s air tube damage.

Root Cause Analysis for Instrument Air Tube Damage

During the field visit, the instrument engineer came to know that the Instrument Air tubing to the control valve 05-PRD-CV-A was detached.

So, after doing new instrument air tubing for the control valve 05-PRD-CV-A, the control valve’s stroke checking was done. During valve stroke checking, the operation of the control valve was found smooth. The upstream process plant A was started again and the product was lined up.

As soon as the final control valve 05-PRD-CV-A was given open command, heavy vibration in the line was observed. The vibration in the line did not stop. The final control valve 05-PRD-CV-A was allowed to get stable as it was in auto mode.

After a few minutes, the final control valve 05-PRD-CV-A became stable at 60 % opening. Still, the vibrations in the line were the same. Due to this vibration, the instrument air tubing was also vibrating. This was the main reason for the instrument air tube getting detached.

On further investigation, it was found that the differential pressure across the control valve was not maintained properly. The reference for the differential pressure across the control valve was taken from the datasheet of the control valve.

Because of this excess pressure drop across the control valve, cavitation was also observed. This effect also damaged some portions of the lines also.

Recommendations

After this incident few recommendations came which should be followed by every engineer:

Recommendation 1: All field instruments should be included in the Look Listen Feel round. If the Look Listen Feel of this control was carried properly, then the excess vibrations and abnormal sound of the cavitation could have been captured and attended to during the shutdown time.

Recommendation 2: The differential pressure across all the valves (on-off valves, control valves, and Motor Operated Valves) should not exceed as per the datasheet.

Recommendation 3: If for any valve due to any reason, the vibrations still persist, then the Instrument Air tubing should be changed to the Stainless-Steel Braided Hose. Stainless-Steel Braided Hose will reduce the effect of the vibrations.

This article was published in the Automation Community Competition.

Read Next:

Comments

1

Excellent Analysis. Very useful information.