Magnetic Float Guided Level Transmitter – Pune Techtrol

Description

Magnetic Float Guided Level Transmitter is a highly reliable method for continuous level measurement of various liquids that are chemically compatible with the material of construction of the transmitter.

The float is designed to be used with a variety of liquids and its self-cleaning construction makes it suitable even for sticky or dirty liquids, ensuring that there are no float hang-ups. This level transmitter is an ideal choice for applications where accurate and reliable level measurement is critical.

Magnetic Float Guided Level Transmitter

The Magnetic Float Guided Level Transmitter is a reliable and precise method for continuous level measurement of various liquids that are compatible with the transmitter’s material of construction.

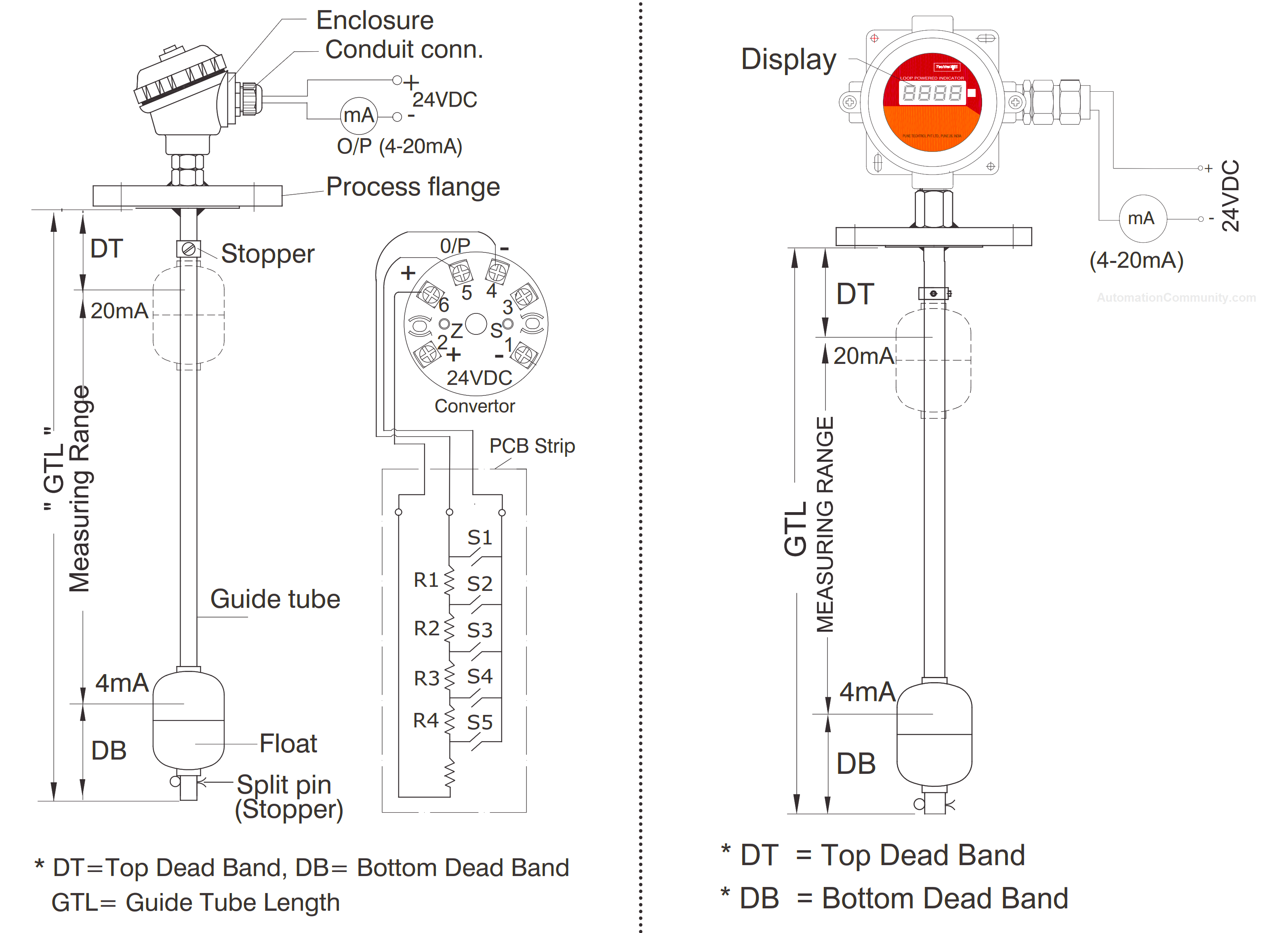

It is composed of a float and guide tube assembly made of non-magnetic material, which allows for undisturbed flux. Inside the guide tube, a closely spaced glass-encapsulated reed switch and resistor PCB strip is placed.

As the liquid level rises and falls, the magnetic float moves and actuates the reed switch, generating a proportional voltage. This voltage is then transmitted to the transmitter located in the enclosure, which converts it into a 4-20 mA signal that can be used with PLC or DCS.

The signal can also be sent to a remote display unit for indication or to a display unit that is integral to the transmitter for local indication. The unique self-cleaning construction of the float makes it suitable for even sticky or dirty liquids, with no risk of float hang-ups.

Installation of Magnetic Float Level Transmitter

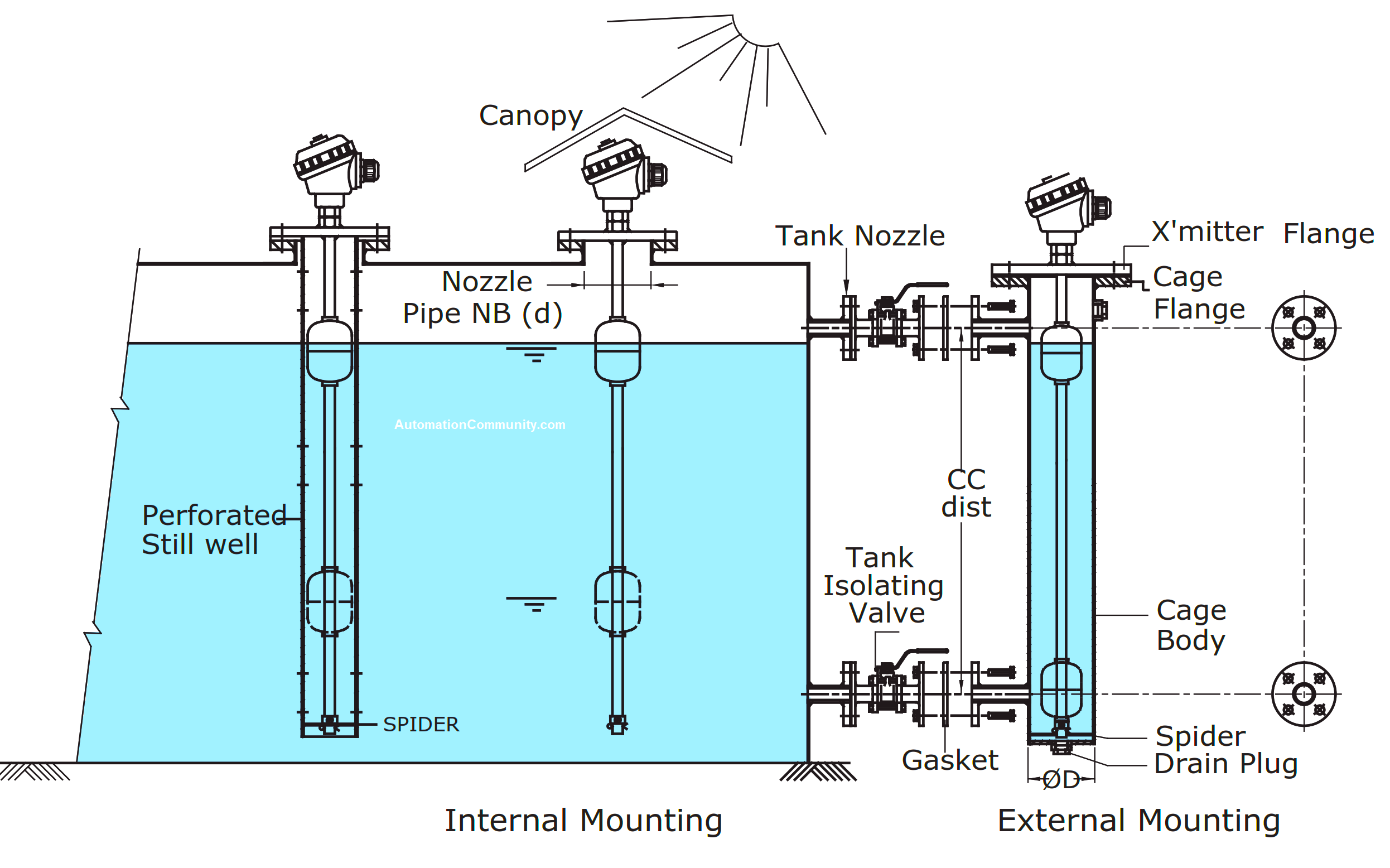

The Magnetic Float Guided Level Transmitter (FGT) is a transmitter that can be mounted at the top of a tank, either internally or externally via an external chamber. It is important to choose a suitable location for the transmitter on the tank where vibrations are minimized.

For tanks with excessive turbulence, a perforated still well is recommended. The process connection of the transmitter should match with the counter connection provided on the tank.

The ID (d) of the nozzle should be greater than the float OD to enable the insertion of the transmitter through the nozzle. If d is less than the float OD, remove the float and re-insert it into the guide tube from below after installing the transmitter without the float.

For external mounting, provide a separate isolation valve on the tank for safety and removal of the level transmitter for repairs and maintenance. It is important to ensure that there is no leakage at the process connection by providing a gasket/tape for flanged/threaded connections, respectively.

For outdoor locations, protect the electronics from severe weather conditions by using a canopy.

Specifications of Magnetic Float Guided Level Transmitter

- Guide Tube Length (GTL): 0.5 to 4 meters max.

- Measuring Range: GTL – (DT + DB)

- Resolution: ±12 mm (standard), ±6 mm (high)

- Installation: Top

- Enclosure: Cast Al. IP66 or Ex d Gr. IIB or IIC T6, IP66 (CCOE certification available optionally), or ATEX Ex d Gr. IIB T6, IP66

- Conduit Connection: PG11 cable gland, polyamide, or ½” NPT double compression cable gland, brass

- Wetted Parts: SS304/316/316L, PP or PVDF

- Float: SS316 x Ø75, Ø90; SS316L x Ø41; PP x Ø75; PVDF x Ø63

- Liquid SG: 0.65 to 1.2 depending on float size.

- Interface Detection: Min 0.2 difference between SG of upper and lower liquid (with SS316 x Ø75, Ø90 Float)

- Process Connection: Screwed, flanged, or tri-clover ferrule

- Supply: 24 VDC (± 10 %)

- Output: 4-20 mA (2 wire) or 4-20 mA + HART (2 wire) or 1 to 5 VDC or RS-485 MODBUS RTU Serial Communication

- Max. Load: 400 Ohms (with current O/P)

- Max. Temperature: 70 deg c – PP, 150 deg c – SS

- Max. Test Pressure: 2 kg/cm2 (PP/PVDF), 10 kg/cm2 (SS), 25 kg/cm2 (Optional)

- Intrinsic Safety Approval: Zener barrier for intrinsic safety to Ex ib Gr. IIB T6

Maintenance Steps

Maintenance is a crucial aspect of ensuring the proper functioning of Magnetic Float Guided Level Transmitters (FGT). Before performing any maintenance tasks, make sure to switch off the supply to avoid any potential electrical hazards.

Verify that all terminal screws are correctly tightened and not loose. Use a soft cloth to wipe the float and guide the tube to remove any sediment particles that may have accumulated.

Inspect the float for any signs of punctures or damage to the guide tube. After completing the maintenance, ensure that the enclosure cover is closed tightly with the gasket to maintain IP66.

The cable should also be firmly secured in the cable gland, leaving no gaps. If the FGT is installed in a hazardous location, do not open the enclosure cover without disconnecting the power supply first to prevent ignition or explosion.

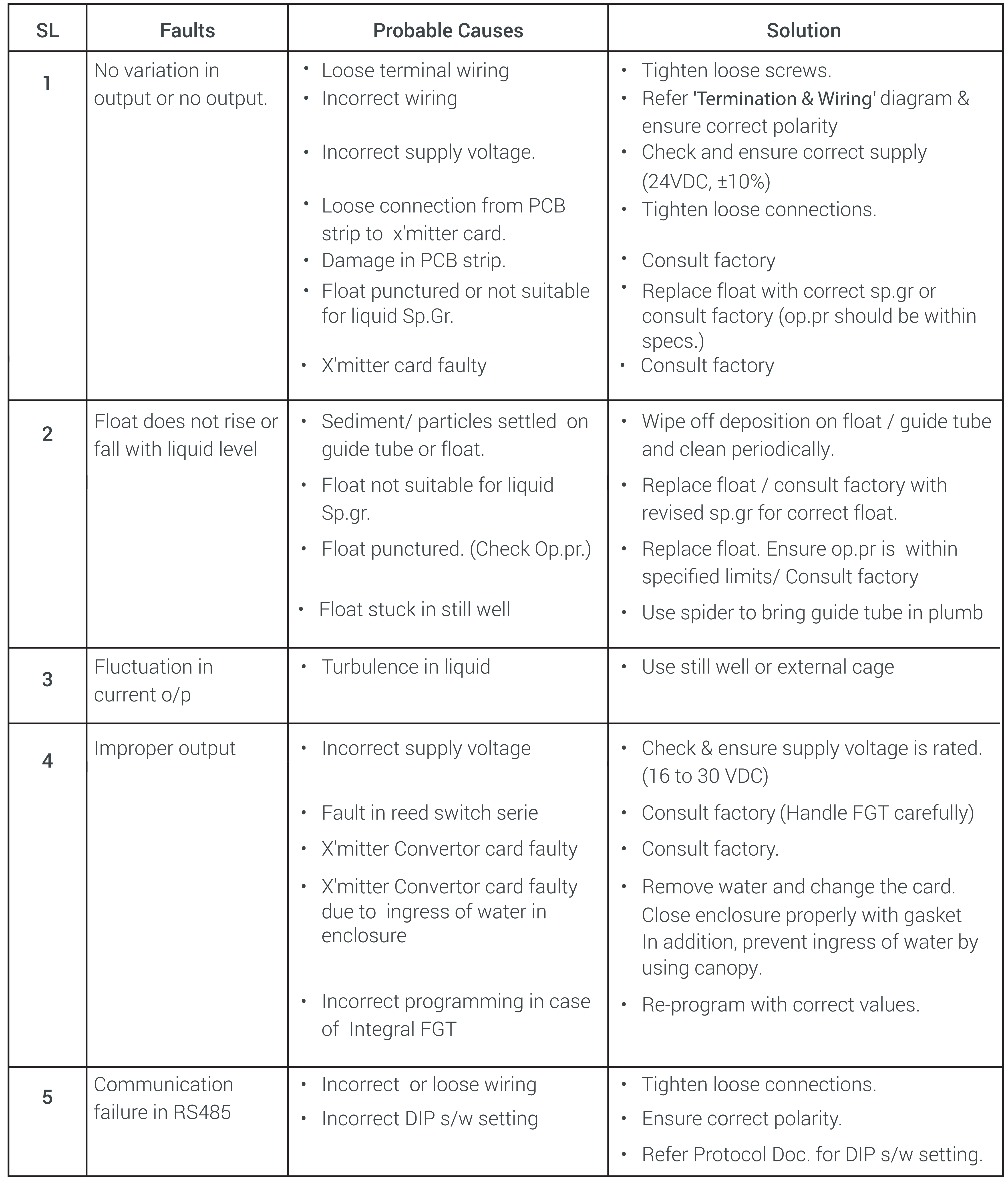

Troubleshooting of Magnetic Float Guided Level Transmitter

Some of the common problems and solutions of Magnetic Float Guided Level Transmitter.

Video

Location

Report abuse

Report abuse

Featured