Displacer Level Transmitter With Torque Tube – Pune Techtrol

Description

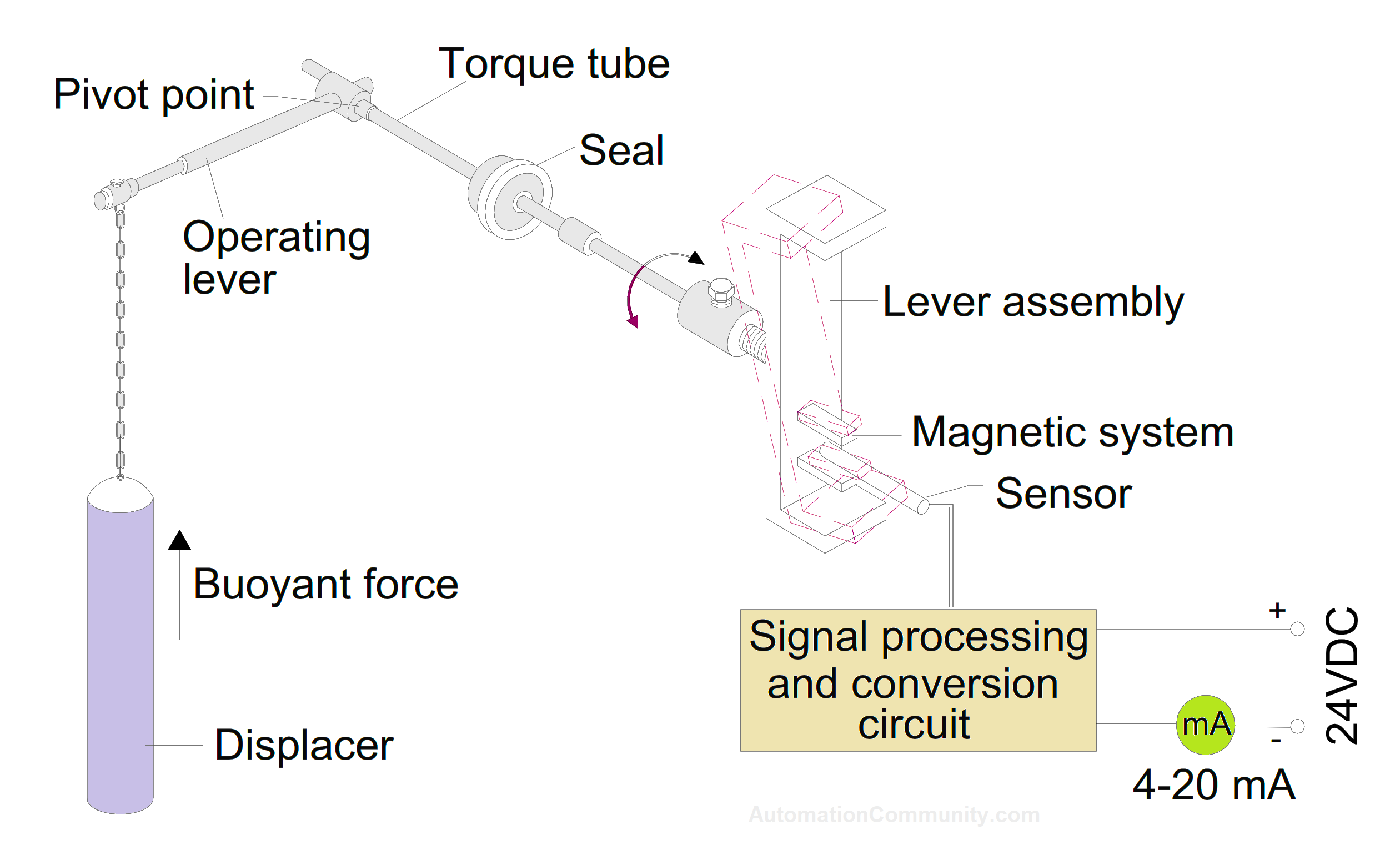

The Displacer Level Transmitter with Torque Tube measures the level and interface level of liquids. The Displacer Level Transmitter comprises a displacer suspended from one end of an operating lever, which is connected to a torque tube at the other end.

Displacer Level Transmitter With Torque Tube

The torque tube is linked to a bar fixture, which is then connected to a compression spring. The enclosure houses a sensor and signal-processing electronics. This assembly is mounted in an external cage for side mounting.

When the liquid level increases, the buoyant force acting on the displacer reduces its resultant weight, which causes the operating lever to twist the torque tube clockwise, resulting in decreased torque force on the sensor through the bar fixture.

When the liquid level decreases, the torque force on the sensor increases. The change in torque force is proportional to the change in buoyant force and is converted into a 4-20mA output.

Displacer Level Transmitter Specifications

- Range: 300 – 3000mm

- Wtd Parts: SS316

- Max Temp: 400°C

- Max Pressure: 60 Kg/cm2

- Liquid Density: ≥ 0.6 g/cm3

- O/P: 4-20 mA

- Enclosure: Cast Al IP66 or Ex-P IIC T6

Installation of Displacer Torque Tube Level Transmitter

The displacer transmitter can be mounted either internally or externally on either the left or right side of the tank.

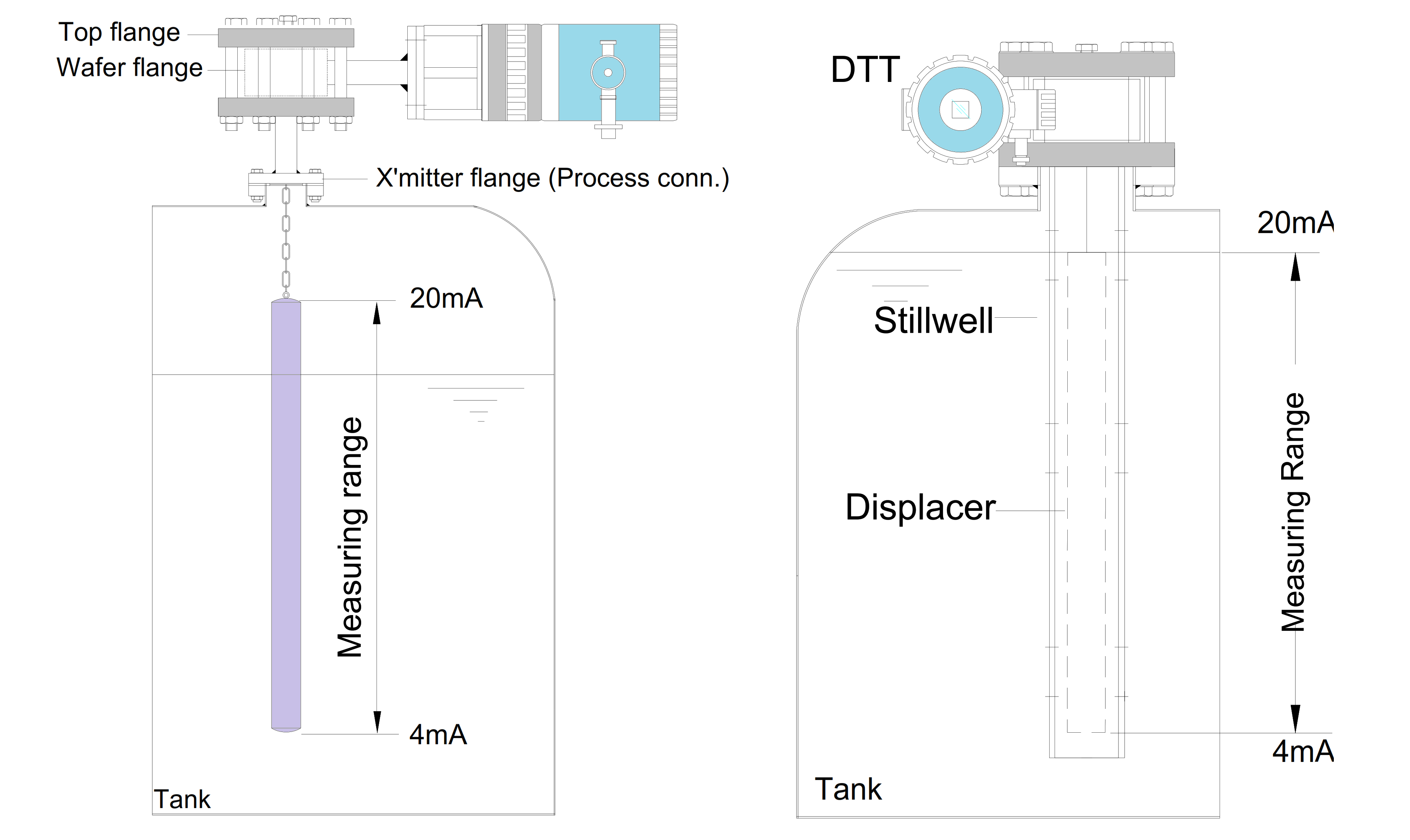

Internal Mounting

When mounting the transmitter internally, it can be supplied without a cage and mounted directly on the tank nozzle flange or with an X’mitter flange. For tanks with liquid turbulence, a perforated still well is recommended.

During installation, it is important to ensure that the tank internals does not restrict displacer movement during operation. The transmitter should be mounted vertically in plumb to allow for undisturbed movement of the displacer and accurate output.

If there is a high degree of agitation in the vessel that could cause the displacer element to swing or bounce, a Stillwell should be installed in the vessel. The stilling tube should have an internal diameter large enough to allow free movement of the displacer element and a vent hole should be drilled at the top to prevent air locks. The tube must be installed vertically so that the displacer element does not touch the tube at any point.

The transmitter should be mounted at a safe distance from the liquid inlet and outlet to prevent any interference with the measurement. Refer to the figure for further guidance on transmitter installation.

Follow the below steps:

- Place a suitable gasket on the tank nozzle flange.

- The transmitter can be mounted in two ways, depending on the available space. If there is enough overhead space, hang the smaller range displacer on the hook before bolting and then lower the full assembly of the transmitter enclosure along with the displacer into the tank, and place the transmitter flange on the tank’s nozzle flange.

- If there isn’t enough overhead space, lower the longer-length displacer partly into the tank first and hold it in place, making sure not to drop it. Then, lower the transmitter enclosure onto the nozzle flange, hang the displacer on the hook coming out from the transmitter flange, and place it on the tank’s nozzle flange.

- If there is no overhead space, the transmitter enclosure can be lowered and placed on the nozzle flange, and the displacer can be mounted through the manhole.

- Align the holes of the transmitter and nozzle flange, insert bolts through the holes, and fasten them with nuts. Use a torque wrench in a zigzag manner in several steps to ensure proper tightening.

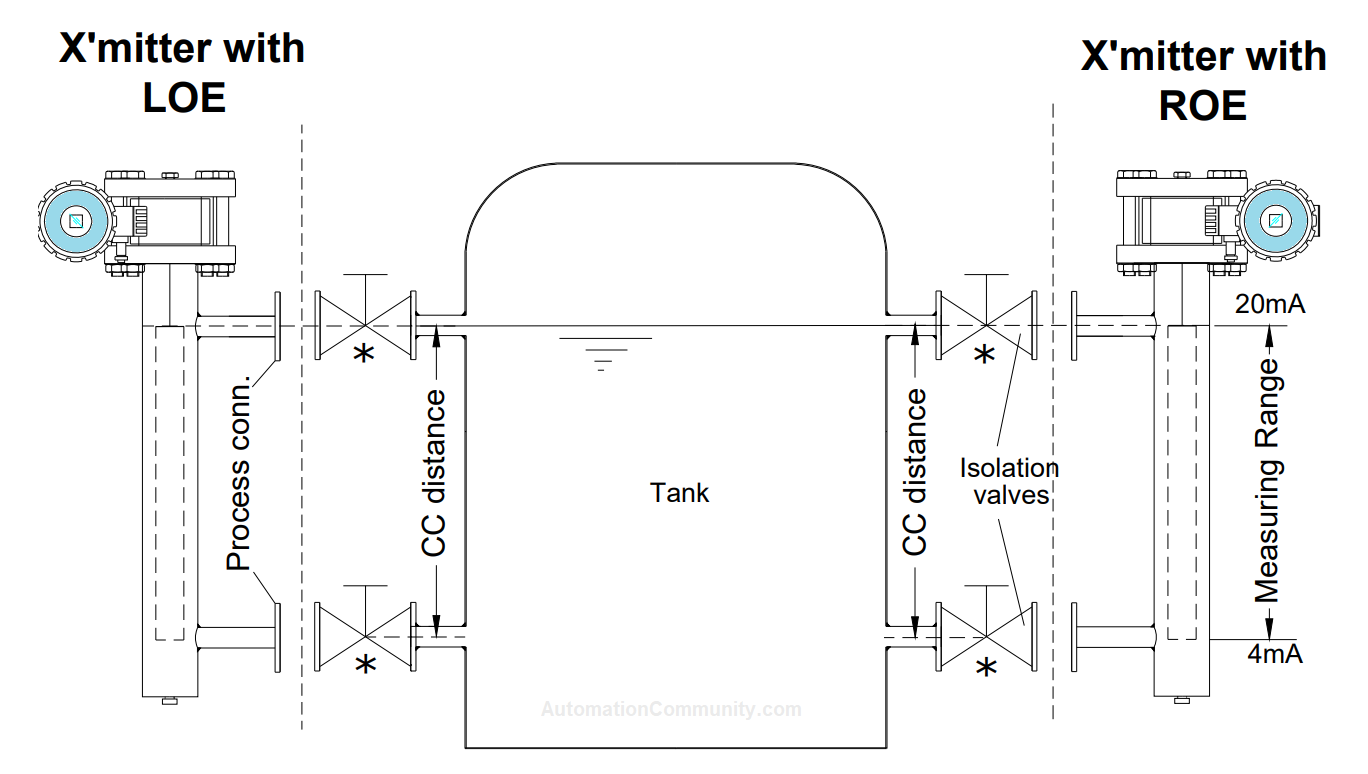

External Mounting

For external mounting, two installation options are available: side-side process connection or side-bottom process connection.

When mounting on the left side of the tank, the transmitter enclosure should be oriented towards the left (LOE), and the process connection for tank mounting should be on the right or rear.

On the other hand, when mounting on the right side of the tank, the transmitter enclosure should be oriented towards the right (ROE), and the process connection for tank mounting should be on the left or rear.

Displacer Torque Tube Level Transmitter Maintenance

The following steps should be taken during maintenance:

- Check for any leakages near the gasket and replace it if necessary. Then re-tighten the bolts.

- Check the displacer for any scaling or buildup and clean it as required.

- Check for any loose electrical connections and retighten them if needed.

- When removing the instrument from a vessel, take care to keep the assembly vertical to prevent damage to the lever assembly.

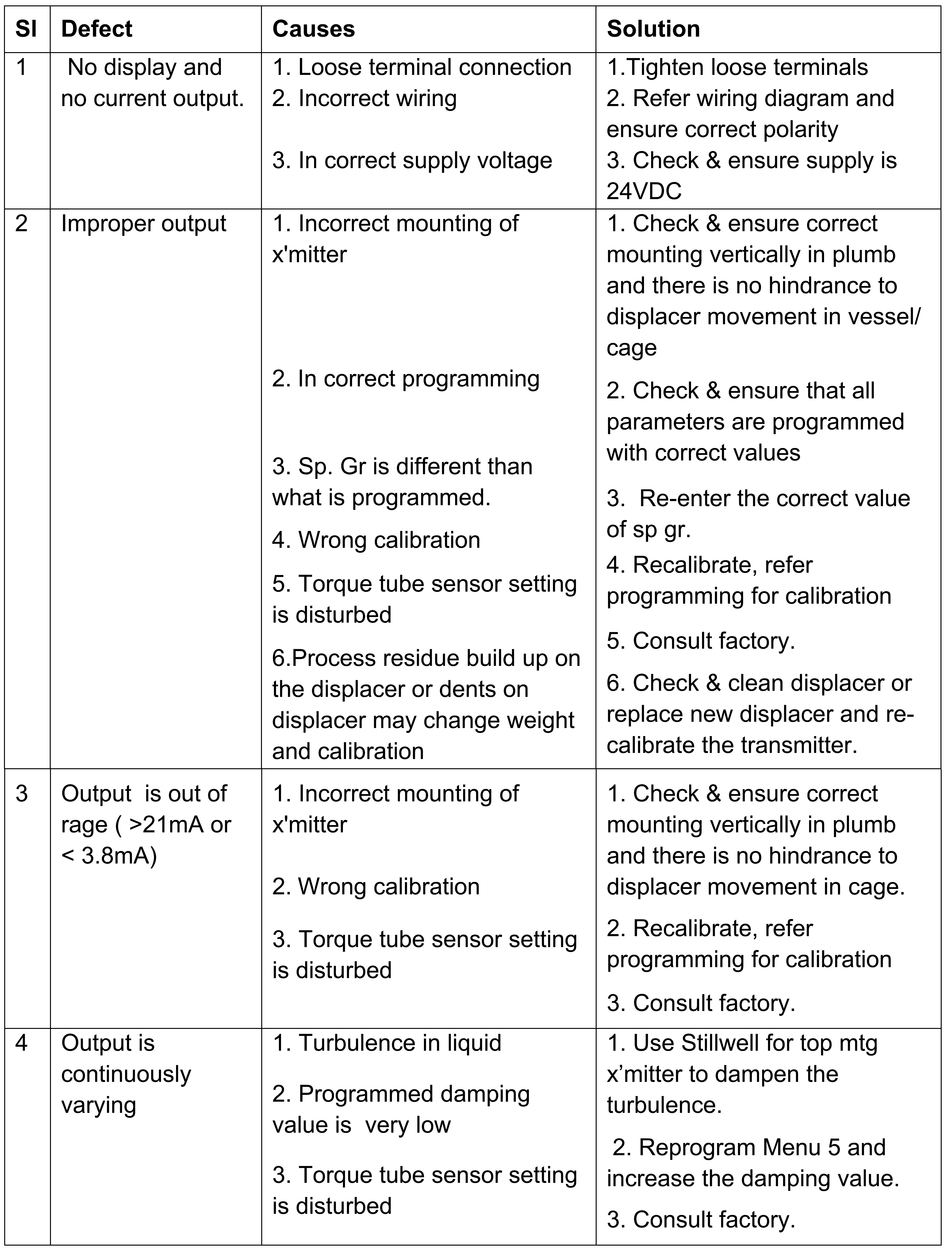

Displacer Torque Tube Level Transmitter Problems and Solutions

Some of the Displacer Torque Tube Level Transmitter Problems and Solutions are mentioned below.

Location

Report abuse

Report abuse

Featured