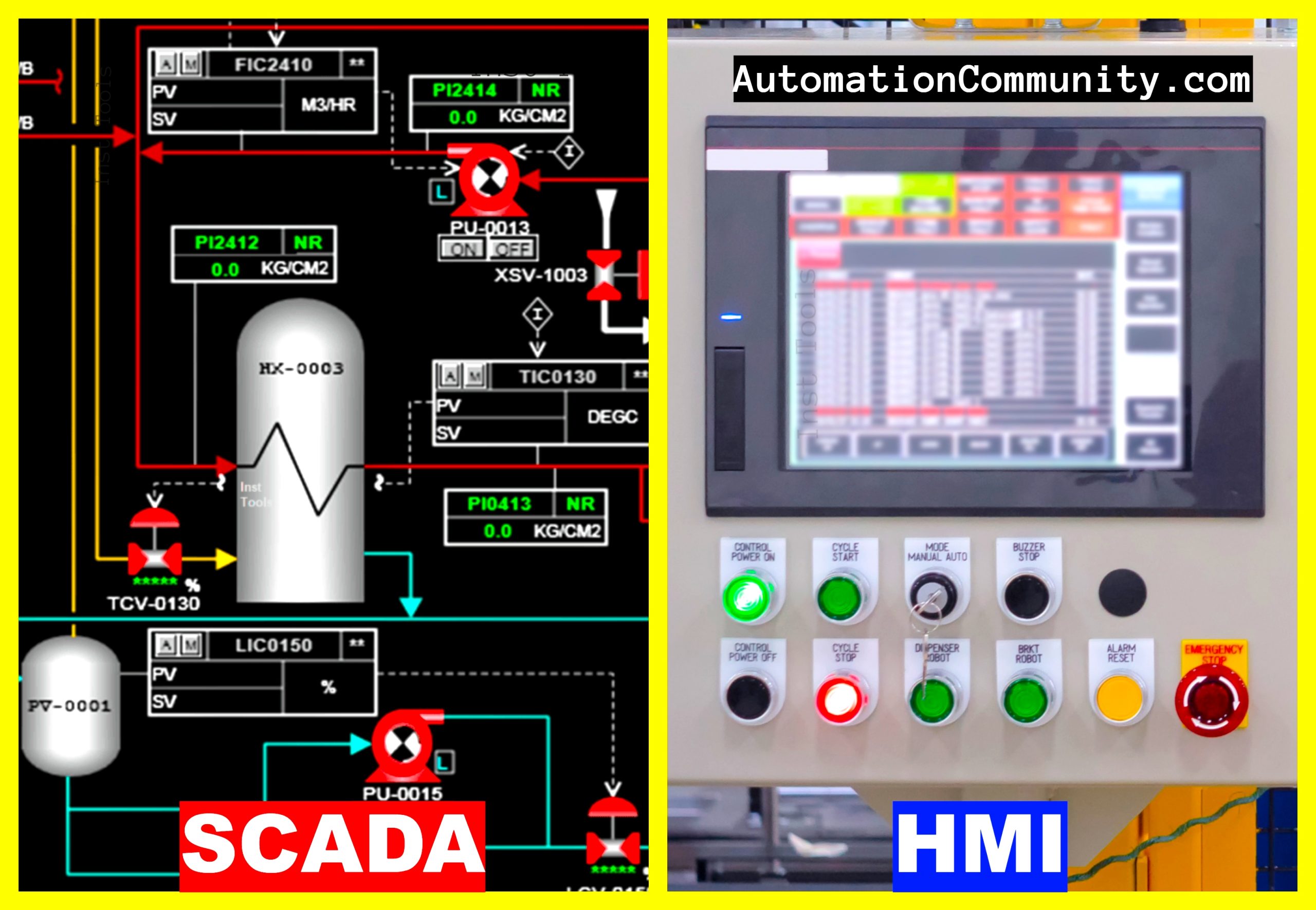

Difference Between SCADA and HMI

In this article, you will learn the difference between SCADA and HMI systems used in industrial plants and facilities for monitoring and control purposes.

SCADA

SCADA stands for Supervisory Control and Data Acquisition, is a software system that is typically installed on computers or workstations. SCADA is a system for monitoring and controlling industrial processes, providing a comprehensive view of multiple systems and processes.

SCADA allows for remote monitoring and control and can handle large amounts of data, displaying it in a structured way. SCADA systems can also be configured to perform advanced control strategies, data analytics, and machine learning algorithms.

Oh, Wait, do You know some other meaning for SCADA which is completely different from this article, it is okay, Read this article on SCADA and HMI.

HMI

On the other hand, HMI (Human Machine Interface) is a simple user interface that is typically available in touch panels or stand-alone simple hardware. HMI is designed for use by operators and provides a localized view of a specific system or process.

HMI systems are easy to use, providing a simple and user-friendly interface for operators to interact with the process locally. HMI typically does not have advanced capabilities like SCADA systems and is mainly used for local monitoring and control of industrial processes.

Difference Between SCADA and HMI

The below table shows the main comparisons between SCADA and HMI systems.

| SCADA | HMI |

| SCADA software installed on computers or workstations or servers | HMI is available in touch panels or stand-alone simple hardware with the HMI software |

| SCADA acts as a graphical user interface between PLC and operators | HMI also acts as a direct interface between PLC and operators but with limited functionality |

| SCADA used for remote monitoring and control of industrial processes | HMI mainly used for local monitoring and control of industrial processes |

| SCADA handles large amounts of data and displays it in a structured way | HMI is Limited in terms of data handling and display capabilities |

| SCADA can be programmed to perform advanced control strategies | HMI is limited in terms of advanced control capabilities |

| SCADA can be integrated with other systems, such as PLC and DCS | HMI is typically standalone and not as easily integrated with other systems or with limited functions |

| SCADA can be integrated with multiple control systems and processes across different locations via networking | Typically HMI are configured with a specific system or process in a single location |

| SCADA provides real-time data visualization and analysis with detailed reports over a long period of time | HMI provides a simple and user-friendly interface for operators to view real-time data and doesn’t have any advanced features like SCADA |

| SCADA can be programmed to create alarms and notifications for critical events via different communication protocols | HMI is limited in terms of alarm and notification capabilities as compared to SCADA |

| SCADA can be used for long-term data logging and storing historical data of process control instruments | HMI is limited in terms of data logging and storage capabilities |

| SCADA provides trend analysis and reporting of data in custom templates as per the user’s requirement | HMI is limited in terms of data analysis and reporting capabilities |

| SCADA can be used to perform batch control and recipe management | HMI is limited in terms of batch control and recipe management capabilities |

| SCADA can be integrated with other software such as ERP and MES | HMI is not recommended for integration with other software |

| SCADA can be configured for access control and security to protect against unauthorized access | HMI does not have advanced security features |

SCADA and HMI are evolving with new technologies, and some of the above limitations may not hold true for all systems.

Conclusion

SCADA provides advanced capabilities for remote monitoring and control, while HMI provides a simple and user-friendly interface for operators to interact with the process locally. Together, both SCADA and HMI systems help to ensure the smooth and efficient operation of industrial plants and facilities.

Read Next:

Comments

2

As applied in industry, this is not accurate. There is significant overlap between the two, but the primary difference is that HMI usually applies to systems that have built in graphical interfaces and SCADA is typically a stand alone product that interfaces with a number of different control systems. However, in general, any graphical system the allows operator insight and control to any control system, no matter the size, is referred to as an HMI. I’ve been a controls engineer for almost 30 years.

Examples of HMI: DeltaV, Honeywell Experion, FactoryTalk View SE.

Examples of SCADA: Wonderware, Ignition, iFix.

I liked to study This course here