What is CODESYS? – Controller Development System

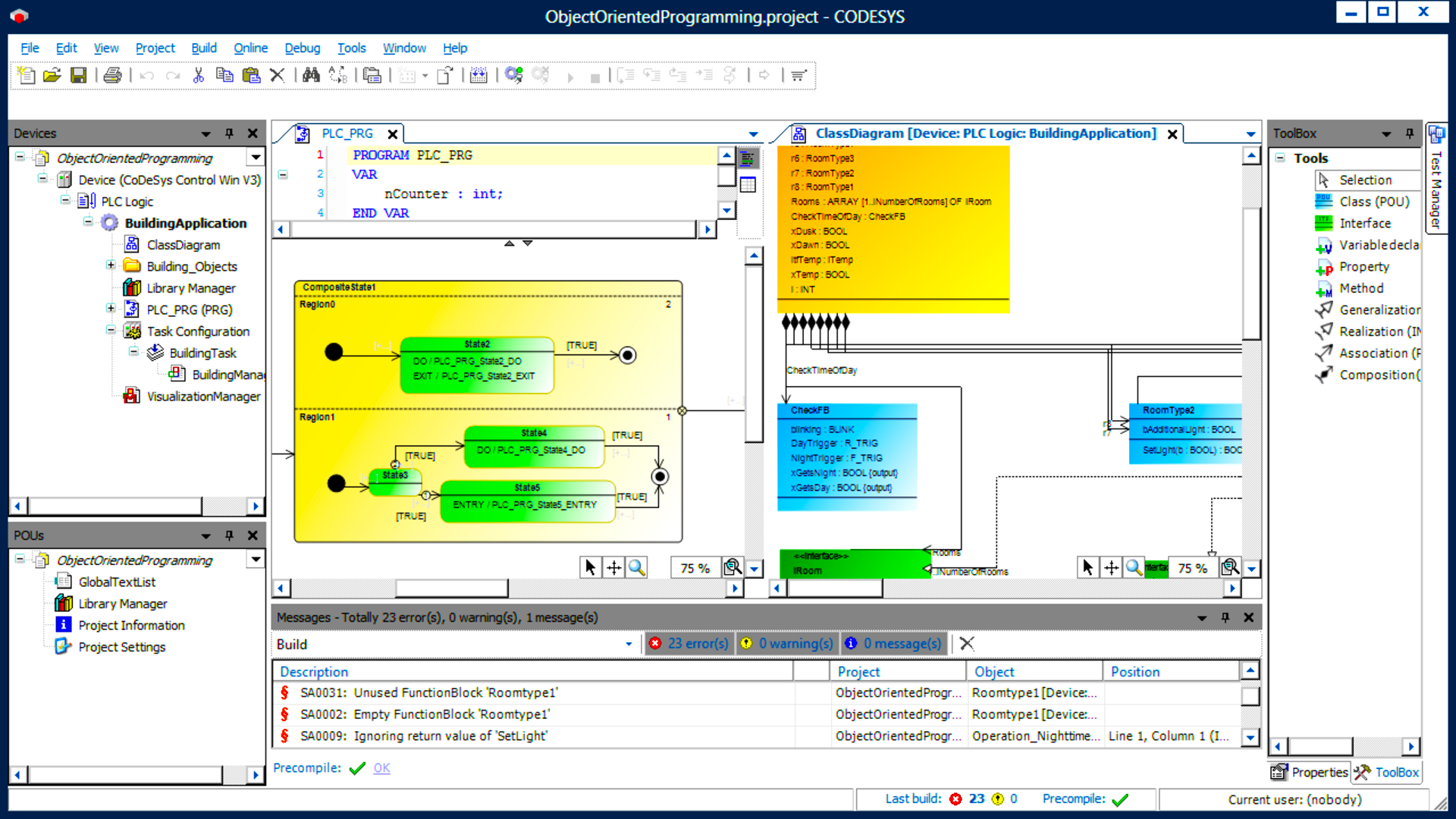

In industrial automation, PLC programming has five types of languages – ladder logic, structured text, functional block diagram, instruction list, and sequential flow chart.

PLC programmers are well-versed in all these languages. Basically, PLC manufacturers either develop their own software coding or hire a third-party source for integrating their software into it. In the second case, one of the most universal software codes in industrial automation is Codesys.

In this post, we will learn about Codesys software and understand how it works in industrial automation.

What is CODESYS?

Let us first understand the basics of PLC software manufacturing. Leading PLC manufacturers in the world like Siemens, Rockwell, Schneider, B&R, etc. either develop their own software or use a platform like Codesys to integrate their software into their PLC hardware.

Basically, this is done to reduce their time for development, reduce cost and in short, allow the programmers to work on a universal platform.

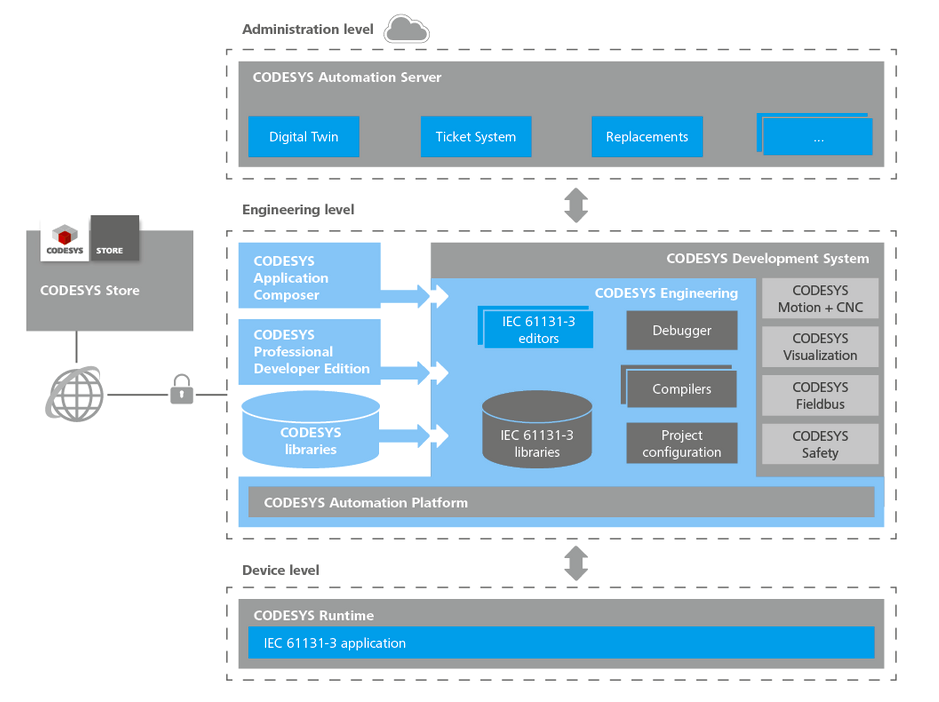

So, what is Codesys? CoDeSys stands for the controller development system. Codesys is a software suite developed by a German company named 3S (Smart Software Solutions) to provide automation programmers with a universal platform for programming PLCs. Its standard is IEC 61131-3.

Codesys, as discussed earlier, can be used with any PLC manufacturer and is hardware independent. So, for example, if a programmer has two different PLCs – Schneider and B&R, and if the software is Codesys-compliant, then the programmer can easily co-relate the programming and develop the logic quickly.

Basically, it will have the same design look, environment, tools, libraries, and features to develop the logic.

The second big thing common in Codesys software is runtime. The runtime executes applications developed in the CODESYS Development System and serves the visualizations for those applications to clients. Due to this, the programmers can see animation tables and visualize the program online in a similar fashion.

Programmers can get a big advantage from upgrading their skills. If the platform is the same, then they will get time to learn more things in deep, instead of hopping between various platforms and learning them.

Mastering such software can make them independent of any programmer or manufacturer support. It can thus be termed as the Android of PLCs – independent of any hardware manufacturer.

Read Next: