Transparent Tubular Level Gauge (TTG) – Pune Techtrol

Description

The Transparent Tubular Level Gauge (TTG) is an inexpensive and dependable solution for directly measuring liquid levels in clean conditions with low temperature and pressure.

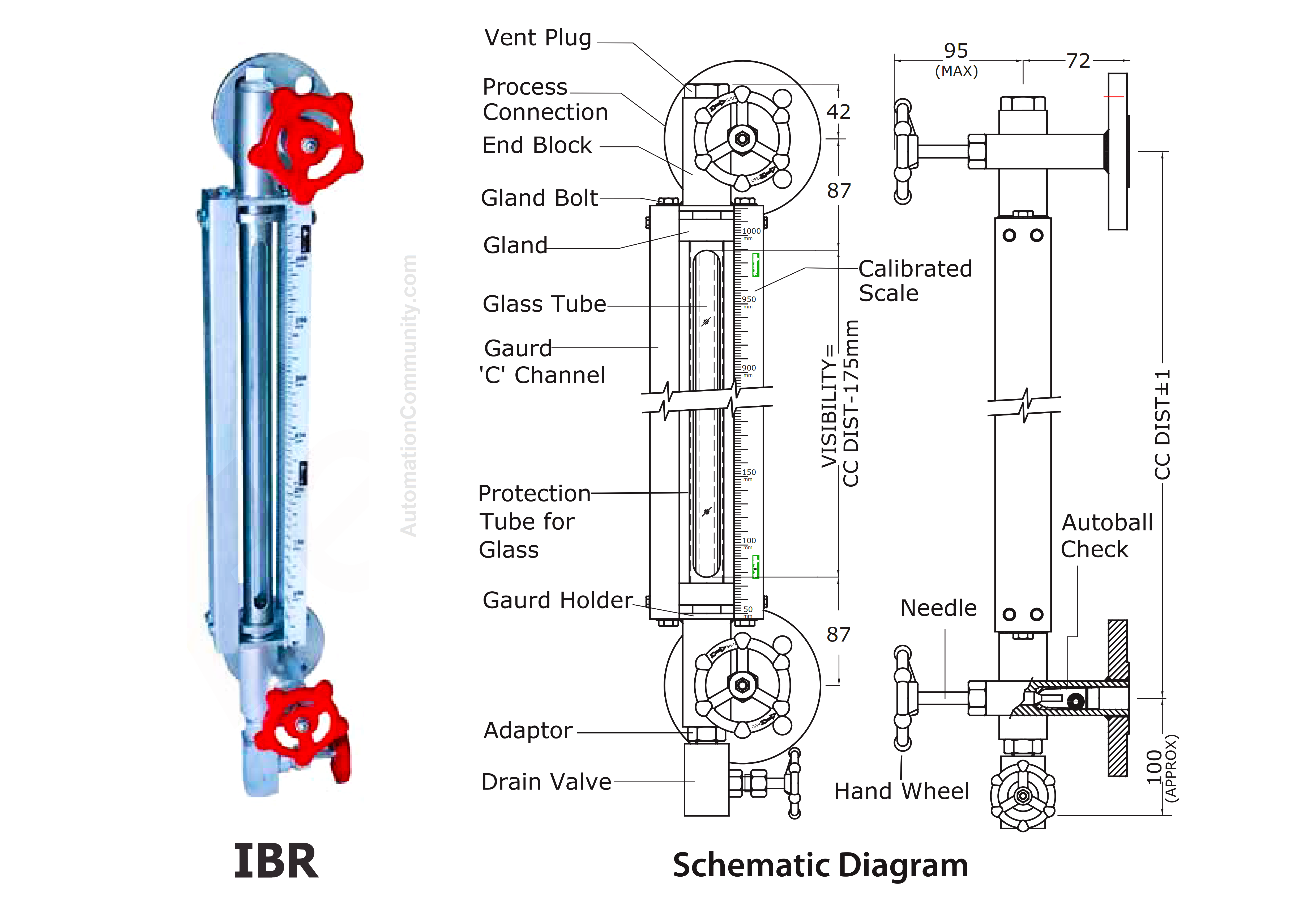

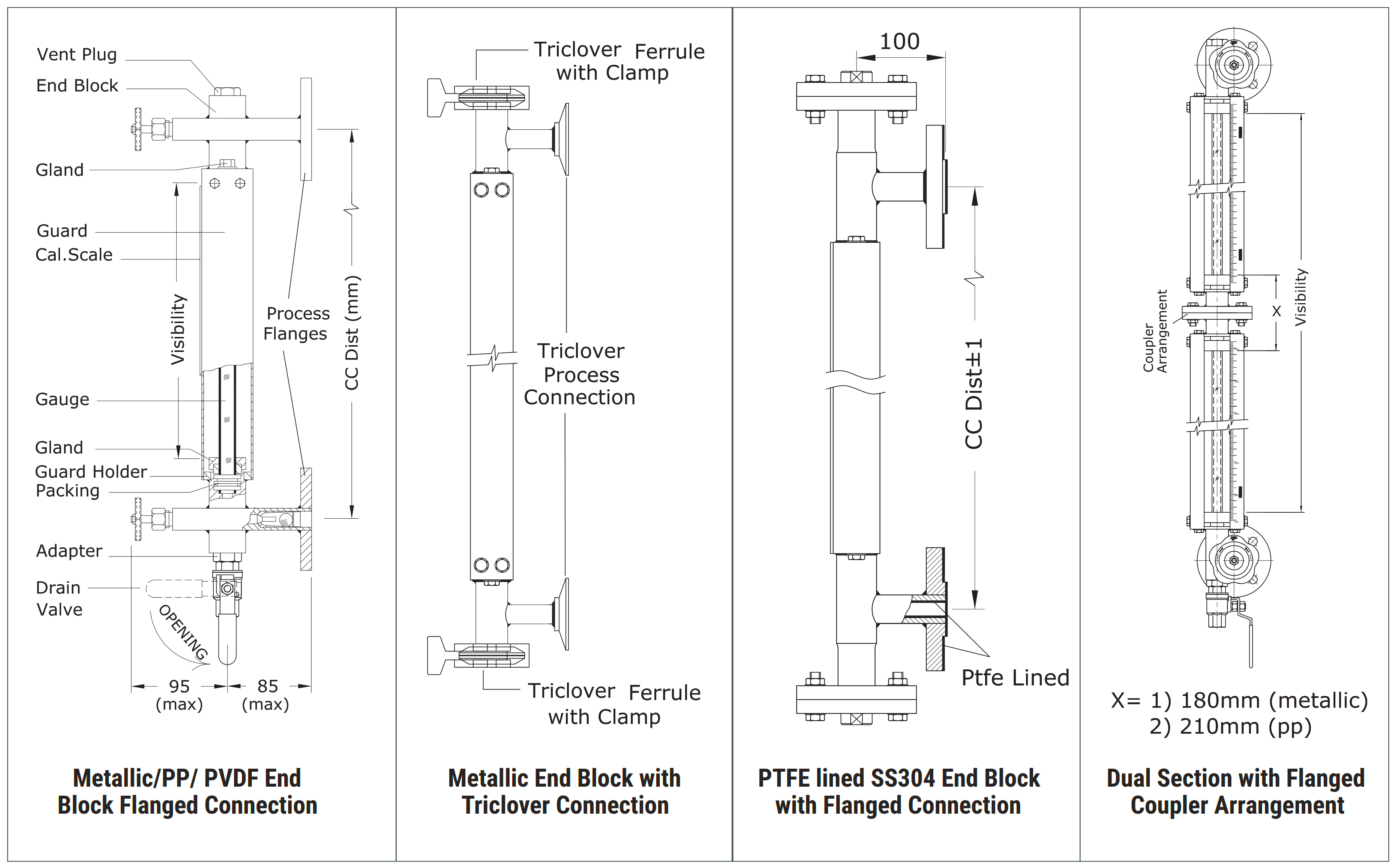

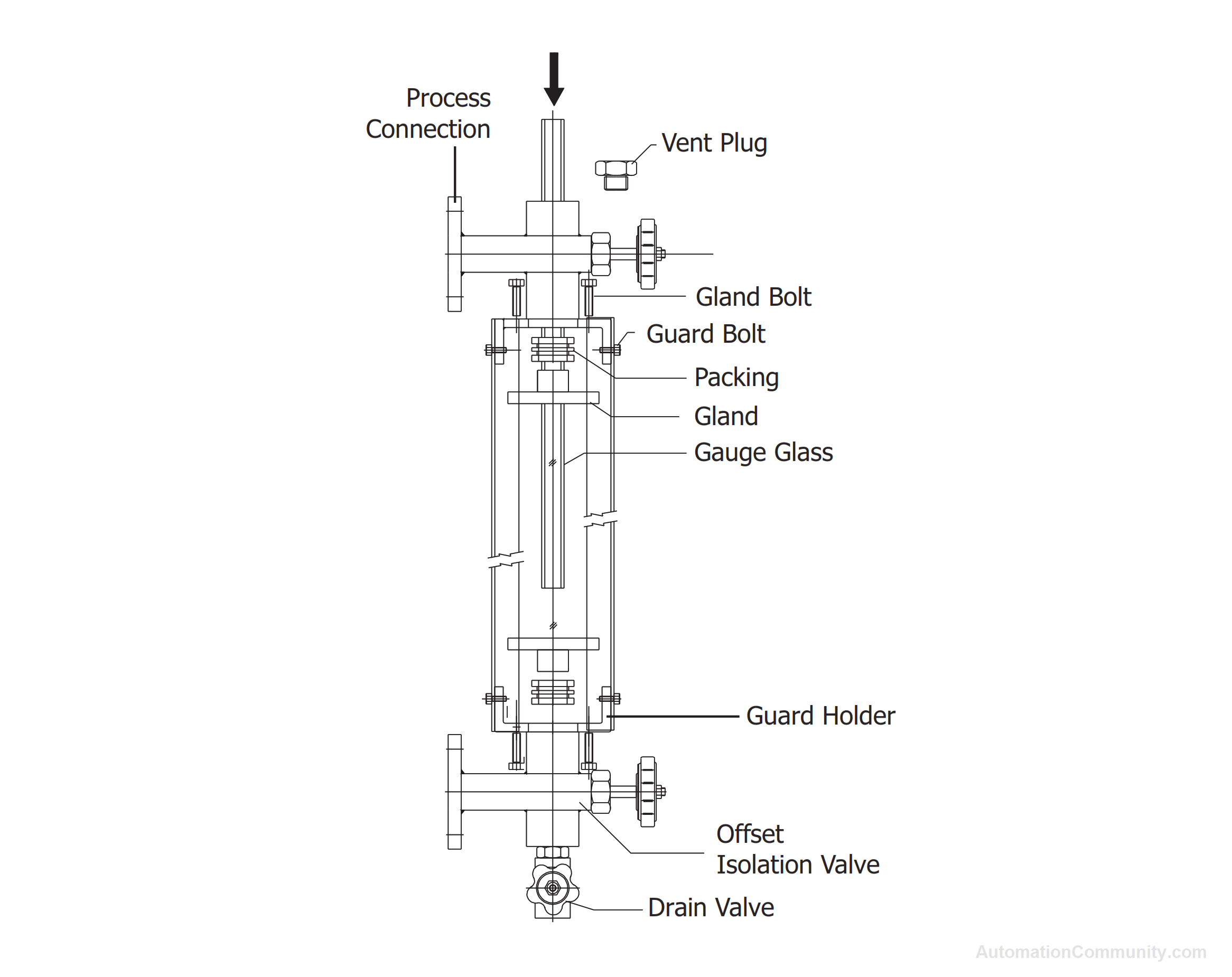

The Transparent Tubular Level Gauge is installed by inserting it between two end blocks, with gland packings ensuring a tight seal. To ensure accurate level measurement, it should be mounted parallel to the tank in a closed-loop configuration, allowing the tank liquid to level itself in the level gauge. Protective ‘C’ channels or tie rods are included to safeguard the gauge against any unintentional damage. The end blocks are equipped with a vent plug, drain valve, and built-in offset valves for added convenience.

The offset valves enable easy cleaning of the gauge glass and its removal without disrupting the process. There is a wide range of materials of construction available to suit various applications. In the case of corrosive liquids, PTFE-lined gauges can be used.

IBR (Indian Boiler Regulation) certified gauges are also available for steam service upon request.

Specifications of the Level Gauge

- Gauge: Tempered Borosilicate Glass (HW) x 16 mm OD (25mm OD for viscous liquids)

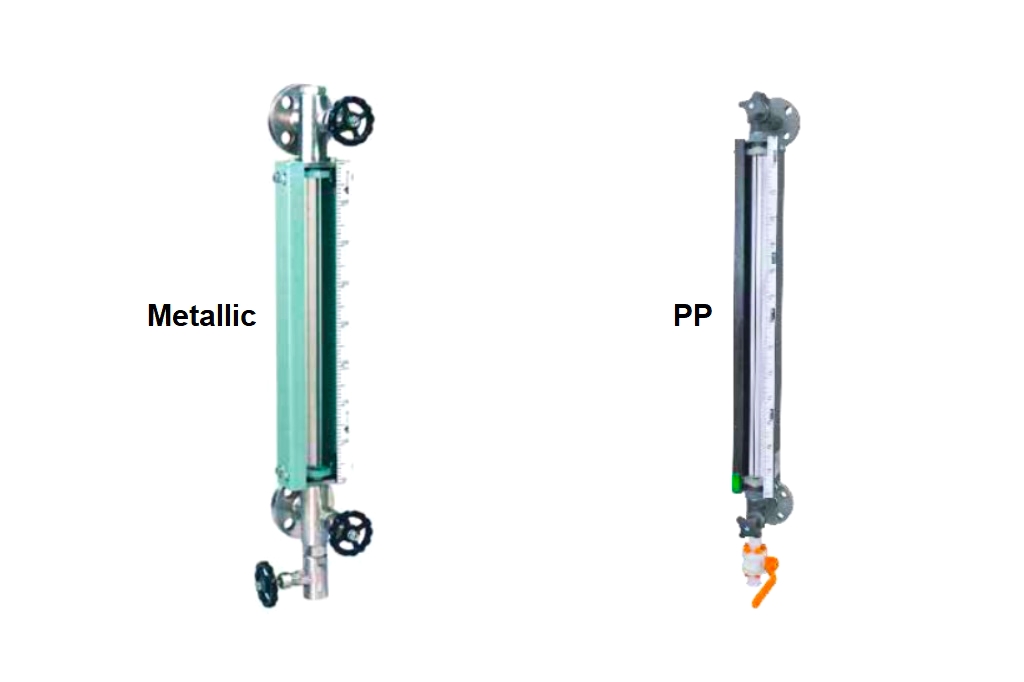

- End Block MOC: CS / SS 304 / SS 316 / PP / PVDF

- End Block Type: w/o Valve/with Integral Offset Valve/with Integral Offset Valve + Autoball check

- Guards: ‘C’ Channel (CS/SS304/FRP); Tie Rods (CS/SS304)

- Gland MOC: CI / SS 316 / PP

- Packing: PTFE

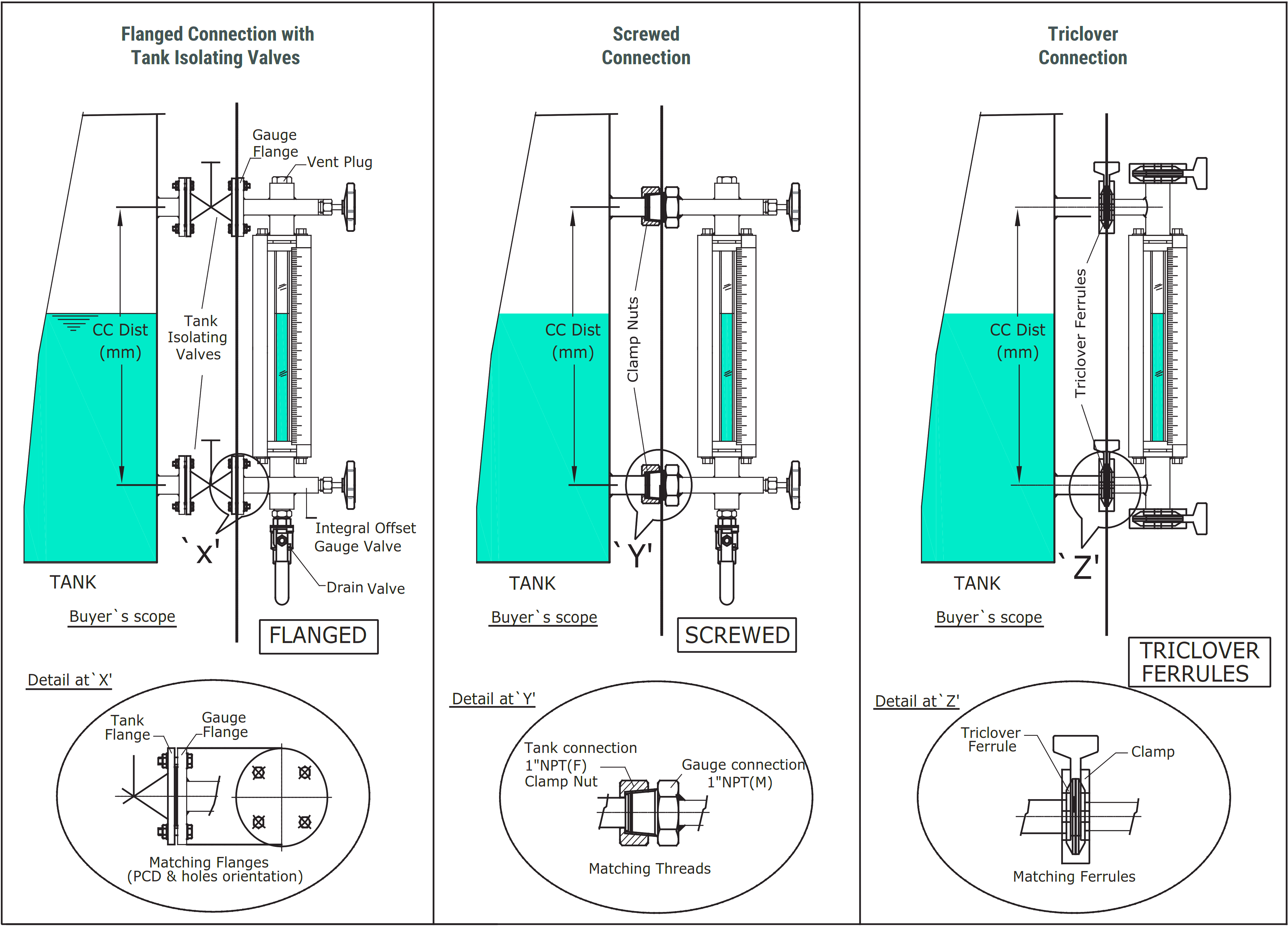

- Process connection: 1″ Flanged (ANSI 150#) or BSP Screwed (M)

- Vent / Drain: Plug / Ball valve

- Calibrated Scale: Polycarbonate (LC=2mm) / SS(LC=10mm)

- CC Distance: 300 to 1500mm (single gauge) 1500 to 3000mm (2 gauges) through coupler

- Visibility: CC Dist – 150mm

- Maximum Temperature : 200°C (Metallic)/100°C (PVDF)/70°C(PP)

- Test Pressure: Vacuum to 10 Kg/cm2 (Metallic) (at amb temp) Vacuum to 2 Kg/cm2 (PVDF/PP)

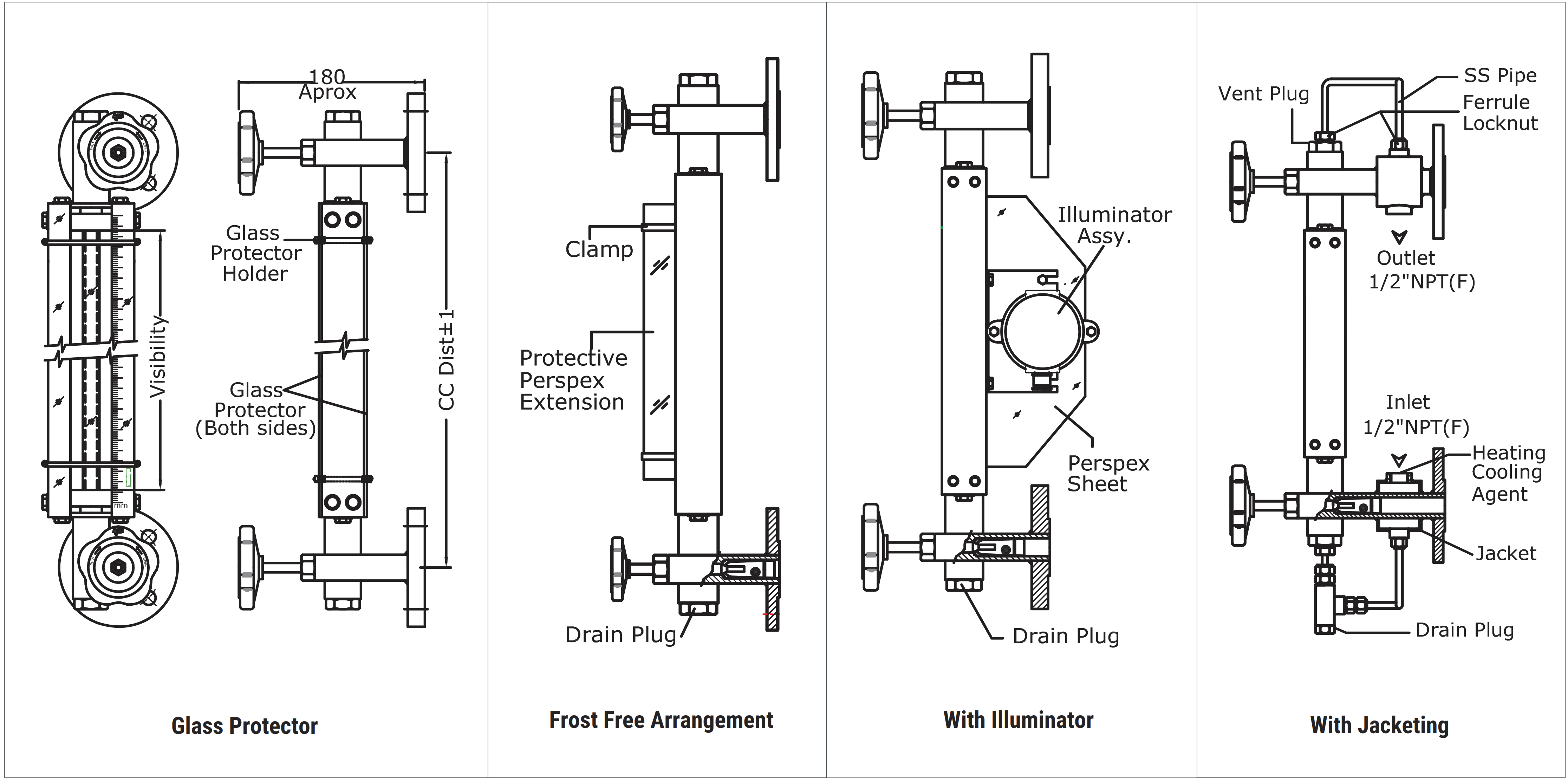

- Additional options available: Autoball check, Illuminator, Frost-Free Extension, Steam Jacketing, Spring Loaded or Weighted Valve suitable for marine applications.

Installation of Tubular Level Gauge

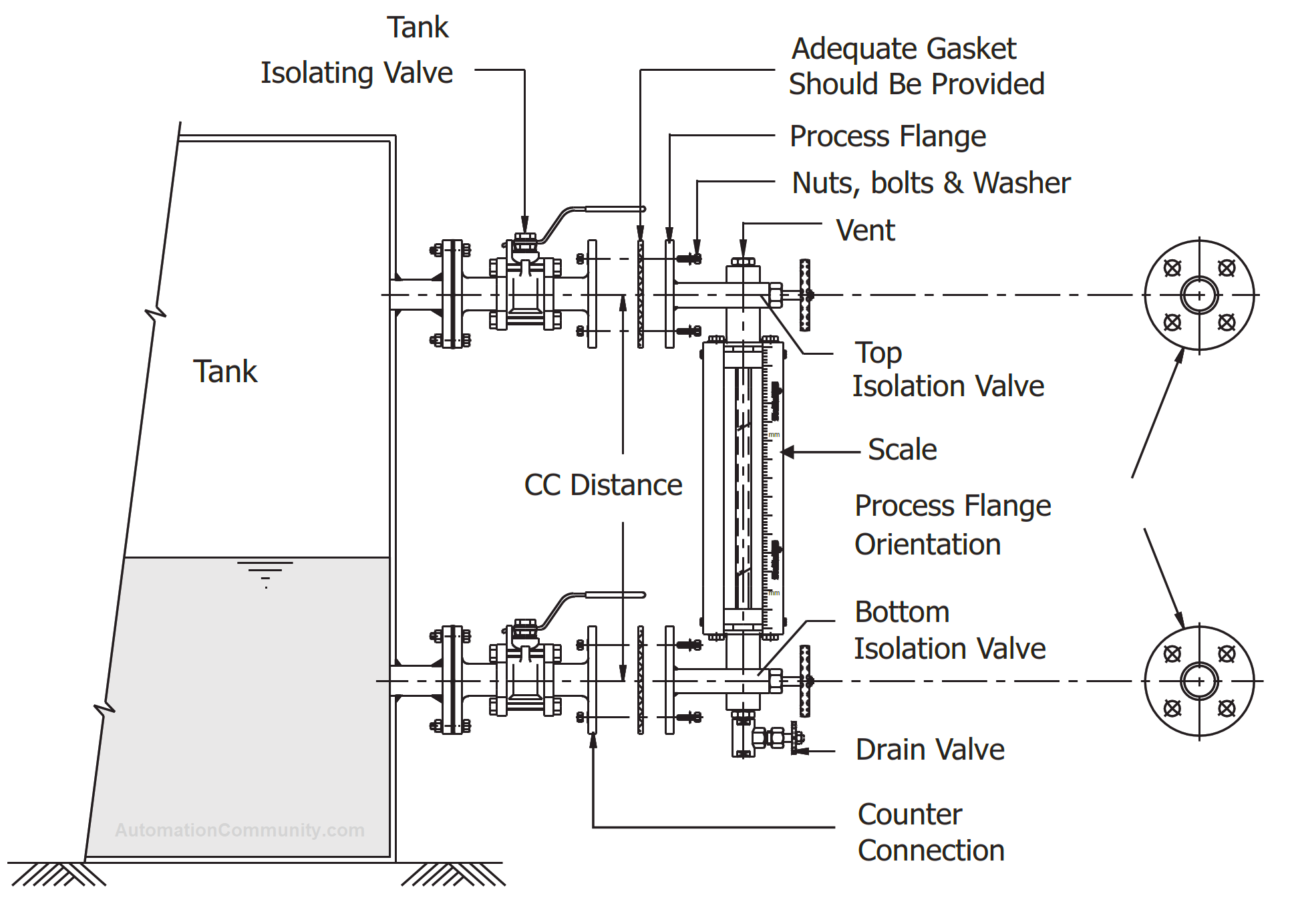

- Choose a suitable location on the tank where there is minimal vibration.

- Verify that the process connections and center-to-center distance of the level gauge match those on the tank. For flange connections, ensure that the level gauge flange matches the counter flanges on the tank, and their pitch circle diameter orientation is identical. For screwed or SMS union connections, check that the threads and type match.

- Confirm that the counter connections provided on the tank are vertical and in a plumb line.

- Place appropriate gaskets between the flanges and apply the appropriate thread sealant between threads before bolting to prevent leakage through the joint.

- Do not connect any pump suction or outlet for the process at the drain point of the gauge.

- Install a separate isolating valve on the tank for safety and to facilitate the removal of the level gauge for repair or maintenance.

Maintenance of Tubular Level Gauge

Under normal circumstances, “Tubular Level Gauge” does not require any maintenance. However, if the liquid being measured contains dirt or suspended particles, it is essential to clean the gauge glass periodically to ensure accurate readings.

Cleaning of Level Gauge Glass

To clean the gauge glass of a Tubular Level Gauge without removing it, please follow these steps:

- Close both isolation valves to stop the flow of liquid through the gauge.

- Drain the liquid from the gauge glass by opening the drain valve.

- Clean the gauge glass using a soft wire brush or by passing compressed air through the top vent.

- If dirt or debris remains on the gauge glass, use trichloroethylene to clean it.

Level Gauge Glass Removal/Replacement

A. Replace old gland packings, in case they have become hard. The following steps should be followed:

- Close both isolation valves.

- Open the vent plug.

- Unscrew the gland bolts carefully.

- Remove the gauge glass by gently pushing it upwards.

B. While replacing the gauge glass, it is important to handle it carefully to prevent any damage or breakage.

- Follow the above steps of A.

- Carefully remove the gauge glass and dispose of it properly.

- Clean the gauge glass seating surfaces thoroughly.

- Insert a new gauge glass from the top (vent side).

- Insert packing & gland over the gauge glass from both sides.

- Push the gauge glass into the bottom isolation valve.

- Insert packing & gland into the isolation valve and tighten gland bolts evenly till the gap between gland & guard holder is 3-4 mm.

Applications of Transparent Tubular Level Gauge

The Transparent Tubular Level Gauge (TTG) is used in the following applications:

- This level gauge provides a direct visual indication of the liquid level in tanks.

- This can be used to measure the hydraulic fluid level in hydraulic systems or in filtration systems.

- The TTG is sued to monitor the level of chemicals being added to a process & ensure that the correct amount is added.

- It is used in the water treatment process for detecting the level.

- It can be used to monitor the water level in the boiler drum of steam boilers.

- It is used on ships and bulk carriers to monitor the level of liquids in various tanks, including fuel tanks, ballast tanks, and water tanks.

Special Features of Transparent Tubular Level Gauge

The Transparent Tubular Level Gauge can be equipped with special features such as

- Glass protector

- Frost free arrangement

- illuminator

- Jacketing

- Auto ball check

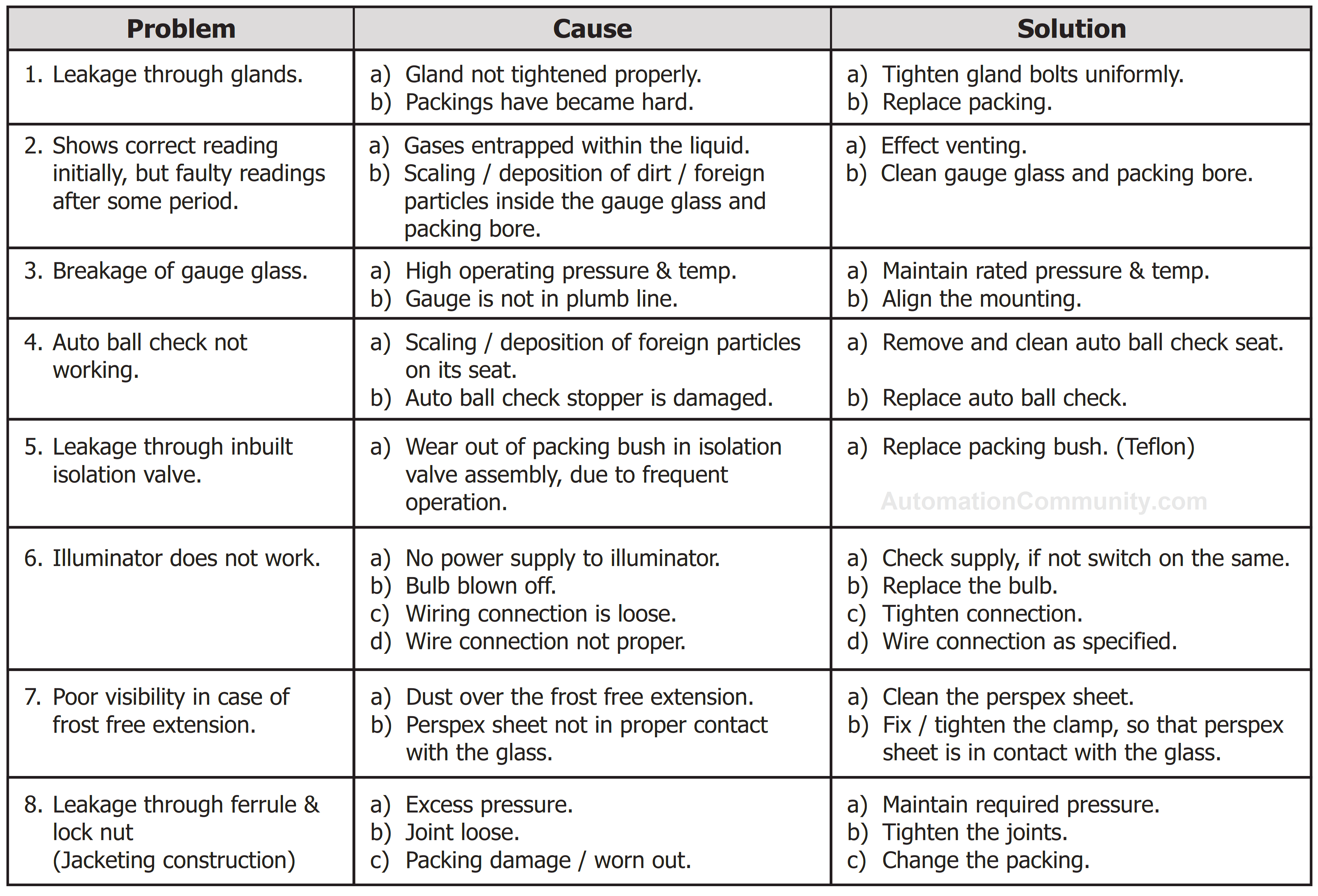

Troubleshooting of Transparent Tubular Level Gauge

The most common problems and solutions of the transparent tubular level gauges are mentioned below.

Video

Location

Report abuse

Report abuse

Featured