RF Admittance Point Level Switch (RFA) – Pune Techtrol

Description

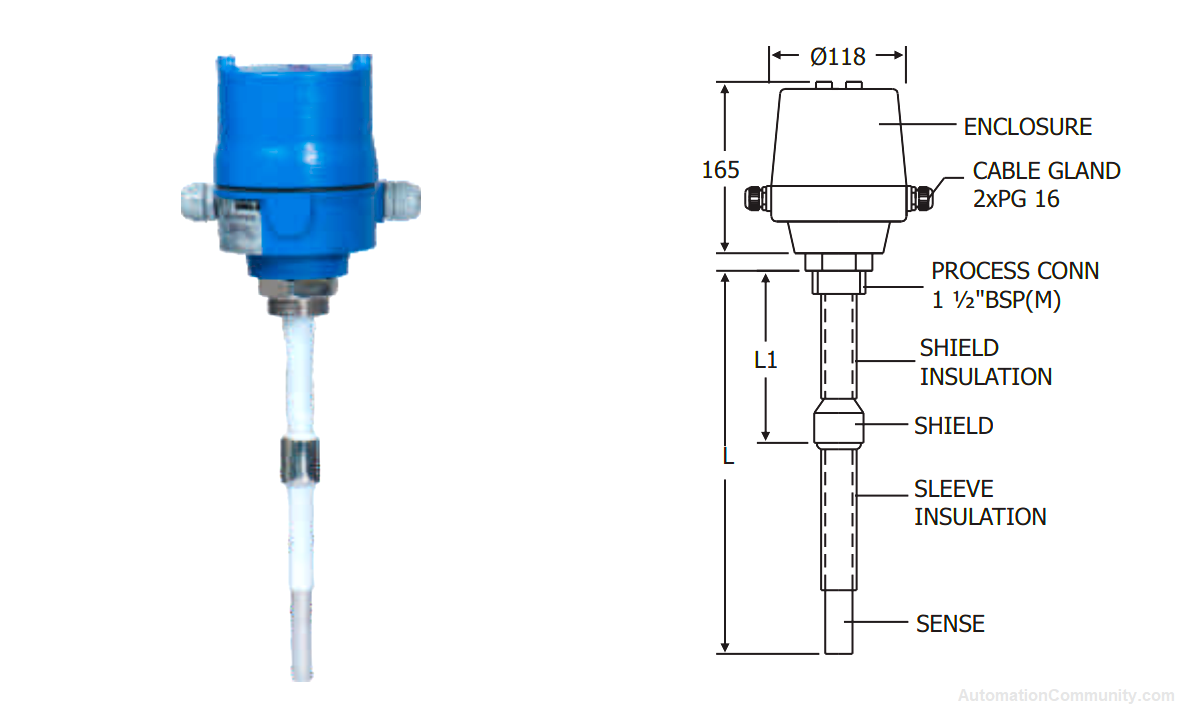

The RF Admittance Point Level Switch, or RFA, is a point-level switch that includes a sensing probe and an electronic switching unit that is integral to the probe.

The sensing probe is composed of three elements: the sensing rod, a stainless steel coat guard shield, and PTFE insulation for liquids or ceramic insulation for solids and slurries.

The use of special electronics and coat guard techniques helps to prevent material from building up on the probe and container wall, ensuring reliable operation.

RF Admittance Point Level Switch

The RF Admittance Point Level Switch works on the principle of admittance, which measures the capacitance of the probe when it is in contact with a material. As the material level rises or falls, the capacitance changes and the electronic switching unit detects these changes and triggers an alarm or control signal. The RFA switch is commonly used in applications involving liquids, solids, and slurries in tanks, vessels, and silos.

The Measuring Section is made up of a sensing rod that is inserted into the material to be measured. The RF signal is transmitted through the sensing rod to measure the level of the material. The Coat Guard Section surrounds the measuring section and prevents the RF signal from being transmitted through any coating or buildup on the sensing rod. The Ground Section is located below the Coat Guard Section and provides a path for the RF signal to be grounded through the material in the hopper.

The combination of the three sections and the special electronics used in the RF Admittance Point Level Switch provides reliable and accurate level measurement, even in the presence of coating or buildup on the sensing rod or container walls.

Applications of RF Admittance Level Switch

The RF Admittance Point Level Switch “RFA” can be used in a wide range of applications. Some of the common applications are:

- Building industry materials: Cement, Sand, Lime

- Foodstuff industry: Milk/Chocolate powder, Coffee, Sugar, Salt, Butter

- Plastic industry: Resin powder & pellets

- Chemical industry: Soda Ash, Talcum powder, Calcium, Slurry, Sludge, Sewage, Coal, Wax, Chromium Acid, Ink, Alcohol

- Agricultural industry: Fertilizer, Wheat Flour, Rice, Barley, Sesame

- Beverage industry: Beer, Syrup

- Other industries: Iron powder, Carbon, Cream, Sodium Carbonate, and Waste Water.

The RF Admittance Point Level Switch is suitable for both liquids and solids, making it a versatile choice for level measurement in various industries.

Installation of RF Admittance Point Level Switch

The installation precautions for the RF Admittance Point Level Switch:

- Mounting of the probe may vary based on construction and application. It can be mounted vertically or horizontally.

- The probe should not be bent or distorted.

- For flat strip probes, the edge of the strip should face the ground.

- The shield element of the probe should extend at least 50mm into the vessel.

- The extended probe should not extend further than necessary into the vessel.

- During filling, the material should not fall directly onto the probe. Use a protection shield if necessary.

- When installing the probe with screw mounting, turn the hexagonal mounting bush of the probe and not the housing.

Specifications of RF Admittance Level Switch

Sensing Probe:

- Type: Standard or Heavy

- Std. Probe Length: 350mm (Max 3000mm)

- Sense rod: SS304

- Coat guard shield: SS304

- Grounding: GI / SS304 (Optional)

- Insulation: a) PTFE (150°C), b) Ceramic (225°C)

- Temp: 150°C / 225°C with GI. temp stand-off.

- Mounting: Top / Side

- Process connection: a) Screwed – 1 ½” BSP (M) (std / Heavy Probe), b) Flanged- 1 ½”NB, BS-10 T ‘D’ (std / Heavy Probe), C) Flanged- 4″ ASA 150 x 10 thk (Disk probe)

Integral Switching Unit:

- Enclosure: Cast Al, Weatherproof (powder coated), Integral with Probe

- Cable entry: 2xPG 16 (Polymer)

- Ambient Temp.: 0°C to 60°C

- Supply: 230 or 110V AC, 50Hz (±15%) or 24VDC.

- Power consumption: 2VA

- Output: 2 Sets of potential free C/O contacts rated at 5Amps, 230V AC (resistive load)

- Switching delay: Continuously adjustable from 2 to 20 secs. probe free and covered.

- Safety operation: Field selectable switch over for min or max (FSL / FSH) switching.

- LED Display: Green – Normal; Red – Alarm; Yellow – Power On

Fail-Safe

The RF Admittance Level Switch offers the option to choose the minimum or maximum fail-safe mode depending on the process requirements. The relay is initially in an energized state and will de-energize when the level changes state, providing an alarm for level changes, mains failure, or instrument failure.

This enhances the overall reliability of the operation. With maximum fail-safe mode, the relay will de-energize when the level surpasses the desired point or in case of main supply failure.

On the other hand, the minimum fail-safe mode will de-energize the relay when the level drops below the desired level or in case of main supply failure. It’s important to note that the contacts shown in the connection drawing are for Fail-Safe High condition, and will reverse when the Fail-Safe Link is changed to the Low position.

Maintenance

Maintenance for the RFA switch typically involves cleaning the probe if material buildup occurs, and ensuring that the cable glands and housing lid are sealed to prevent moisture from entering the electronic components.

Report abuse

Report abuse

Featured