Magnetic Float Operated Pivoted Level Switch (FPS) – Pune Techtrol

Description

Magnetic Float Operated Pivoted Level Switch is a cost-effective device designed for point level switching, suitable for tanks with tops or bottoms that are difficult to access.

Magnetic Float Operated Pivoted Level Switch

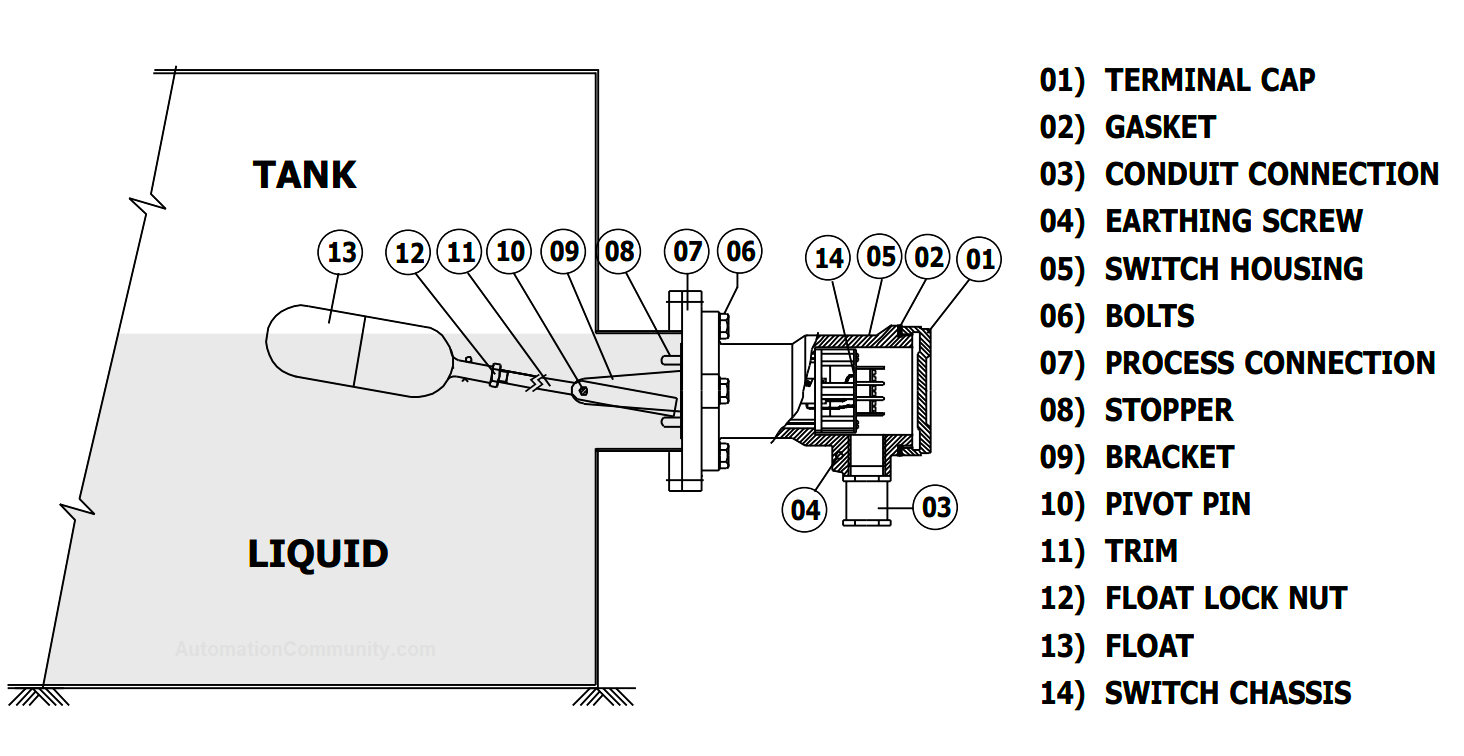

The Magnetic Float Operated Pivoted Level Switch is built with a compact and durable design that comprises a freely moving pivoted float assembly and a switch enclosure made of non-magnetic material, which ensures undisturbed magnetic flux. The device uses dual magnets, with one carried by the float arm and the other by the contact carriers in the switch enclosure.

As the liquid level changes, the like poles of the dual magnets come opposite to each other, resulting in a repulsion force that causes a snap action to change over the contacts. The switch’s magnetic coupling is glandless to prevent any leakage from the vessel to the switch housing.

Installation of Magnetic Float Level Switch

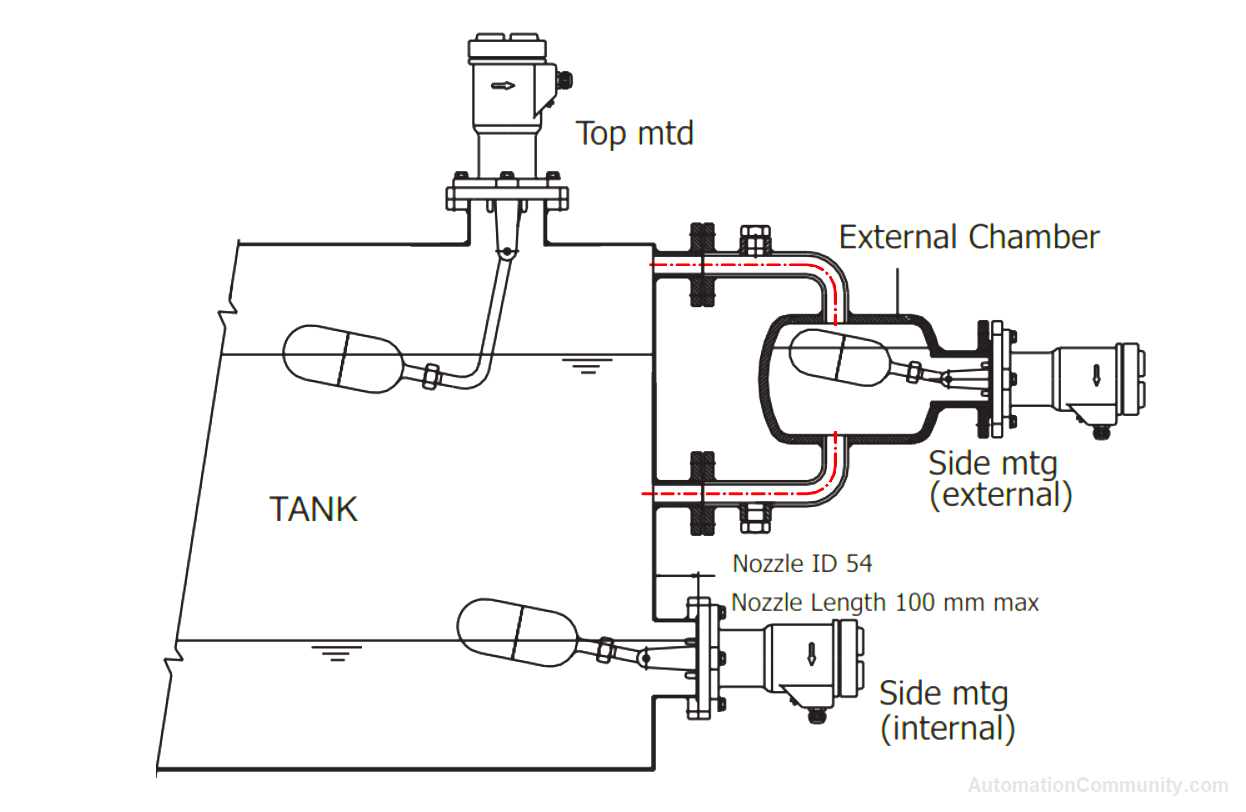

Installation of Magnetic Float Operated Pivoted Level Switch can be done in two ways- internal or external mounting through a chamber. If space is limited or mechanical devices like stirrers are present within the tank, external mounting is recommended.

External mounting also allows for easy isolation for regular servicing, making it suitable for applications like boilers and reaction kettles. Normally, the switch is side-mounted, but for slurry applications, top installation is preferred. The switch can be directly wired to make or break electrical circuits of burners, heaters, motor pumps, alarms, and other electrically operated devices.

Specifications

- Installation: Normally side/top for special applications.

- Enclosure x Cable Gland: Cast Al WP IP65 x PG 11 (Polyamide) or Ex-p Gr IIB or IIC x 1/2″ NPT (Brass)

- Float: SS304 / SS316 / PP / SS304 with PVDF coated.

- Min. Sp. Gr.: 0.6 depending upon float material and dimensions.

- Process Conn.: Flanged or Screwed.

- Switch Type: Micro switch (SPDT / DPDT, 150°C or 250°C) 5A,250V AC.

- Switching Diff.: Fixed (15±5mm). Adjust. between 40 & 300mm depending upon float, trim length & cam positioning.

- Repeatability: ±1mm.

- Accuracy: ±2mm.

- Load/Insulation: Resistive / 150 mega Ohm at 500 VDC.

- Temp. Range: -20 to 250°C and high temp. model up to 350°C.

- Pressure Range: Vacuum to 20 Kg/cm at ambient temp. (contact factory for pressure more than 20 Kg/cm )

- Finish: Regular / Sanitary.

- Special Features: 1) Adj. differential. 2) L/Z cranked trims. 3) High temp. construction with Radiating fins.

Maintenance

Maintenance of Magnetic Float Level Switch:

- Clean the switch frequently if the liquid has high viscosity or contains floating material.

- Check and tighten any loose terminal connections.

- Inspect the contacts of the switch mechanism for pitting or oxidation due to sparking.

- Ensure that the switch enclosure cover is always in place on the enclosure.

- Disconnect the device from the power supply before opening it to prevent the ignition of a hazardous atmosphere.

Troubleshooting

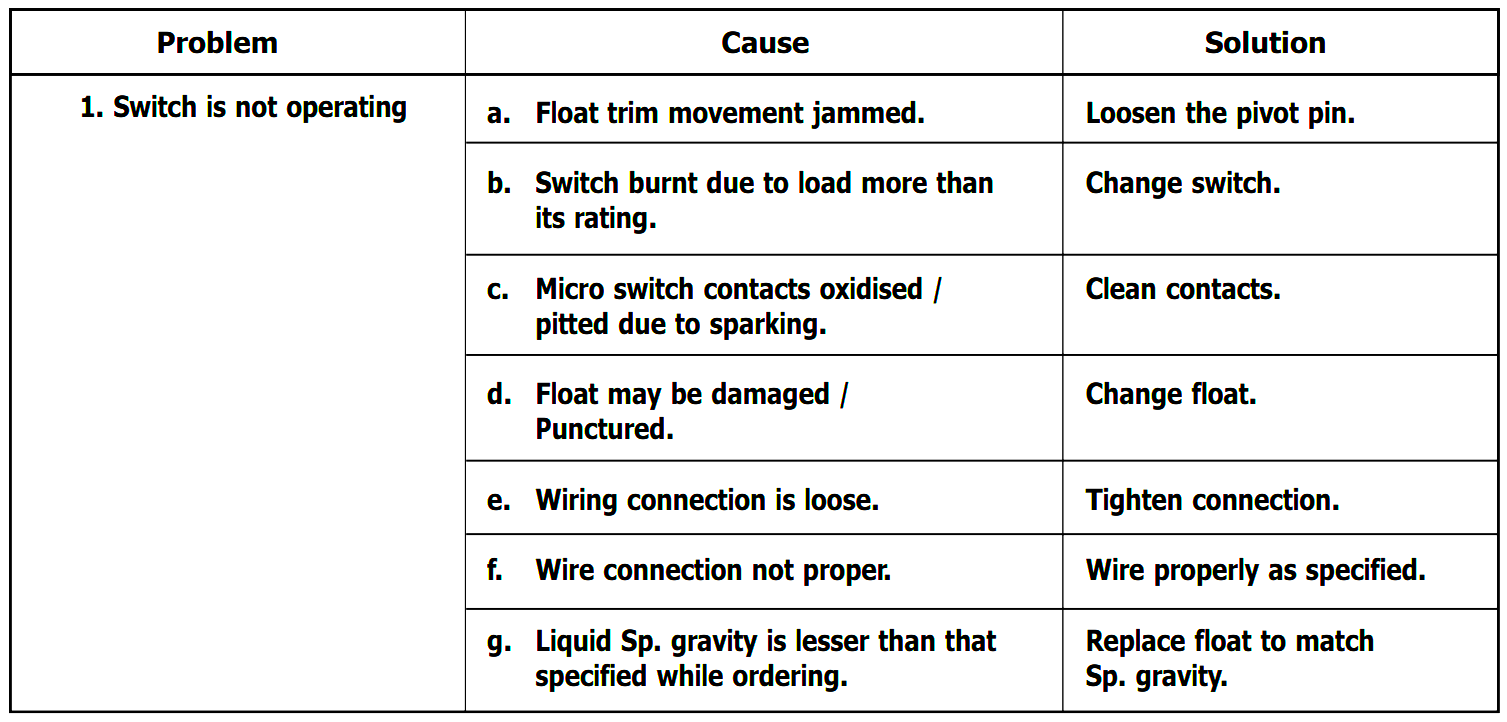

Some of the problems and solutions of the Magnetic Float Level Switch are mentioned below.

Video

Location

Report abuse

Report abuse

Featured