Float and Board Tank Gauge (FBG) – Pune Techtrol

Description

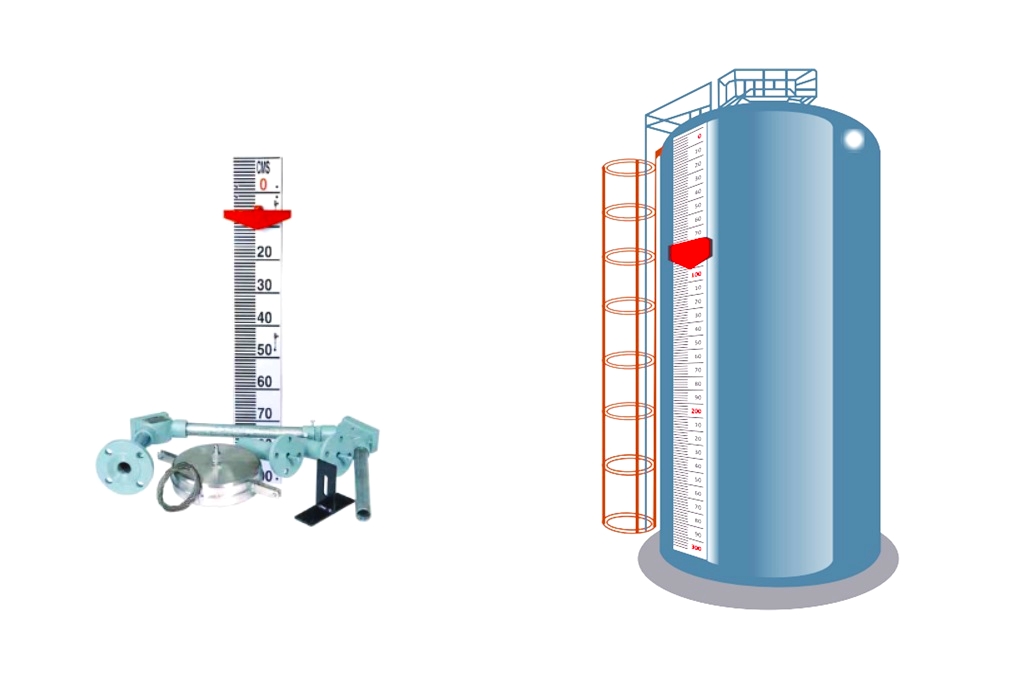

The Float and Board Tank Gauge is an affordable and straightforward solution for directly indicating the liquid level in bulk storage tanks operating at low pressure and temperature.

Float and Board Tank Gauge

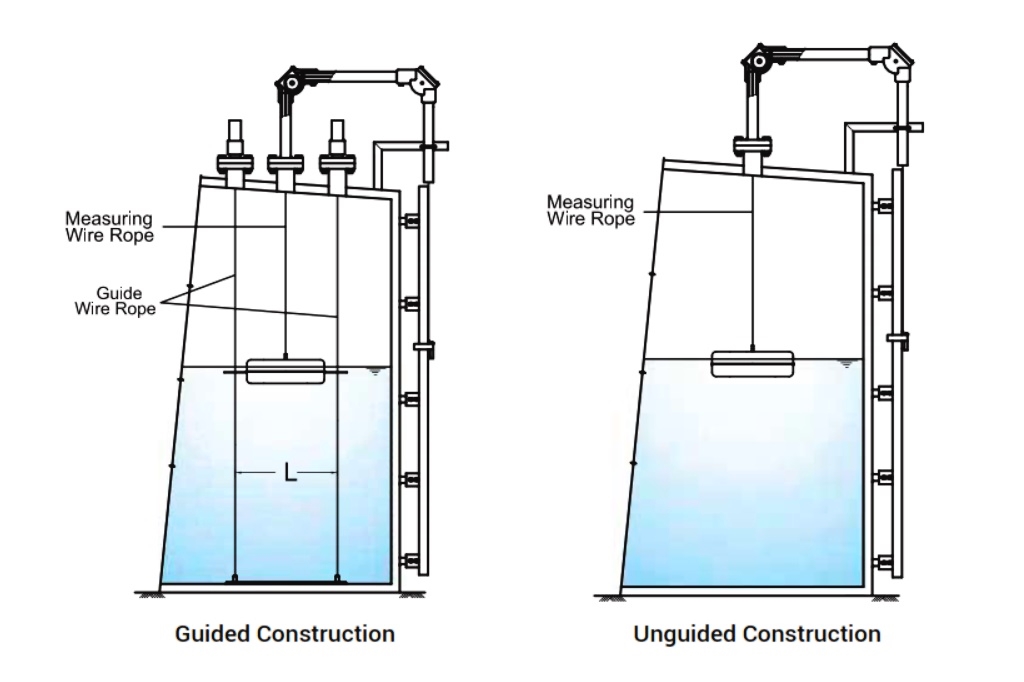

The Float and Board Tank Gauges are available in two types.

- Guided

- Unguided

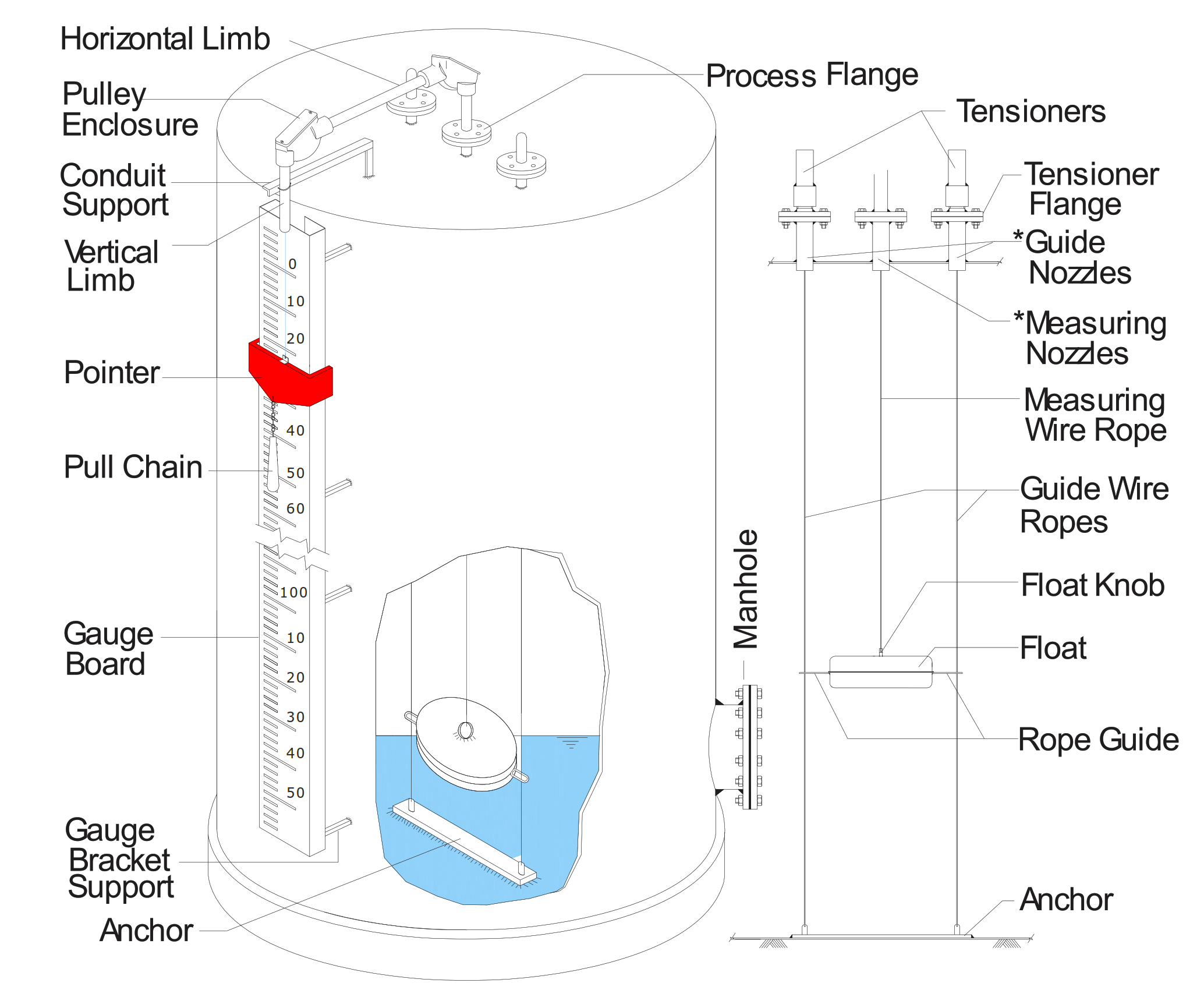

The Guided Type Float and Board Tank Gauge is a reliable and accurate solution for measuring liquid levels in bulk storage tanks. This gauge consists of a float that is connected to a pointer through a rope via a set of pulleys.

As liquid levels change, the float follows the variations in a vertical direction, while horizontal movement is restricted by guide wires anchored to the tank bottom. The pointer is positioned at the top of the gauge board when the tank is empty, and at the bottom when it is full, providing an accurate level indication.

The gauge board can be supplied in multiple 1-meter sections, and gauge board brackets can be used to connect them to achieve the desired measuring range.

Guided Type Float and Board Tank Gauge is suitable for measuring liquid levels with moderate turbulence.

Unguided Type Float and Board Tank Gauge is designed for liquids with minimum turbulence. Unlike the guided type, the float movement in this construction is not restricted through the guide wire as its movement is negligible.

Pointer Travel

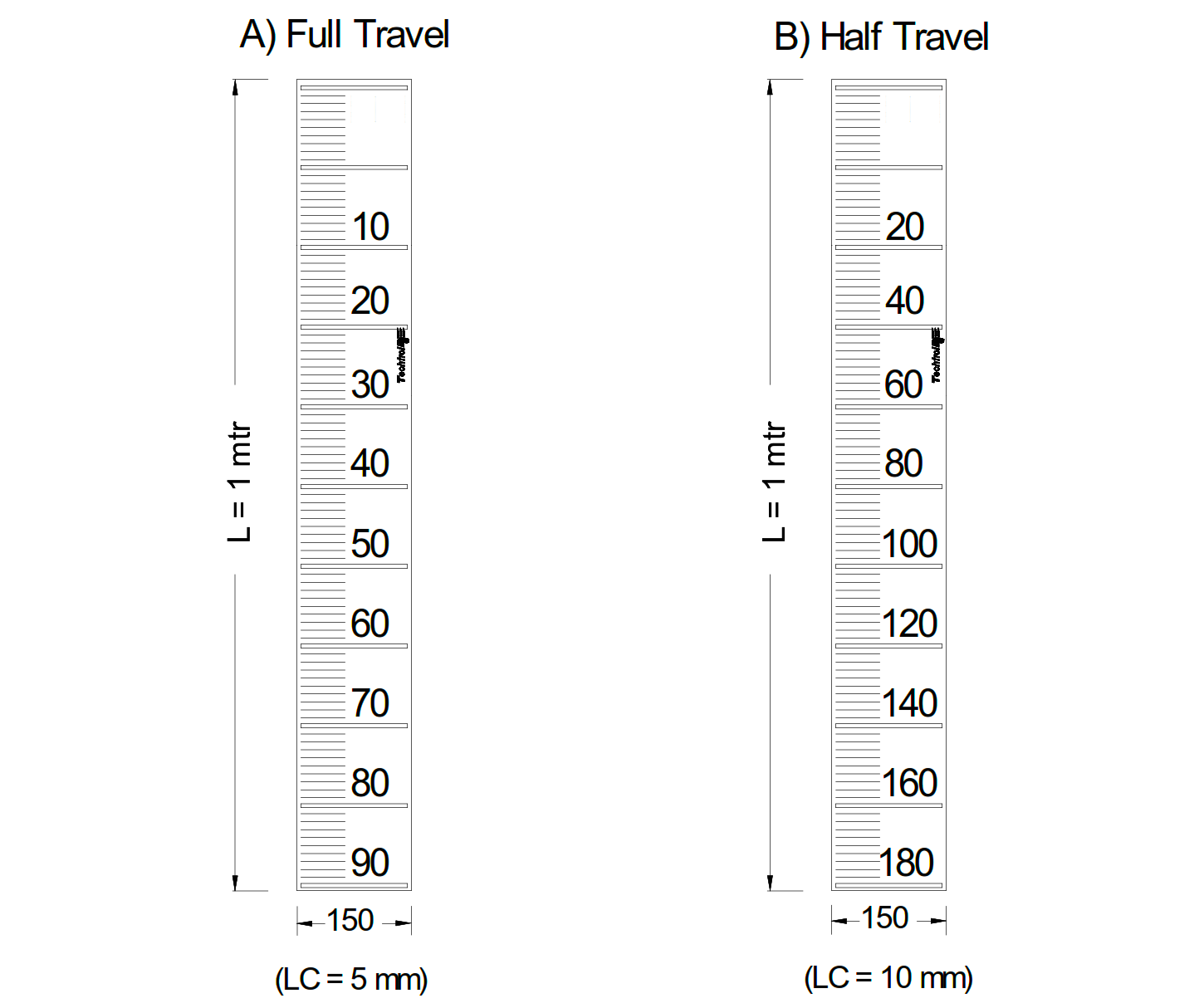

The Guided Type Float and Board Tank Gauge can be installed with either Full Pointer Travel or Half Pointer Travel, depending on the tank’s depth.

Full Pointer Travel is suitable for ground-level tanks, overhead tanks, and underground tanks up to 4 meters deep. On the other hand, Half Pointer Travel is designed for underground tanks ranging from 4 to 8 meters. The gauge board is graduated differently depending on the type of pointer travel.

In Full Pointer Travel, the gauge board is graduated with an LC of 5 mm, while in Half Pointer Travel, the LC is 10 mm. One meter of the gauge board corresponds to 1000 mm in Full Pointer Travel, while it corresponds to 2000 mm in Half Pointer Travel.

A figure is provided above to illustrate the difference in gauge board graduations for the two types of pointer travel.

Product Specifications

- Range: 7.5 meters (with Ø200 float) or 15 meters (with Ø350 float)

- Installation: Ground-level, underground, or elevated tanks

- Liquid SG: ≥ 0.8

- Maximum Temperature: 80 ⁰C (PP), 100 ⁰C (ECTFE Ctd SS), 150 ⁰C (SS)

- Maximum Pressure: Atmospheric

- Float Material: SS304/316/316L, PP, ECTFE (Hallar) coated SS304/316 (Ø200 or Ø350)

- Float/Guide Wire: Rope SS304/316/316L, PTFE ctd SS304/316 (Ø 1.6 mm multistrand), PP (Ø3 mm multistrand)

- Process/Tensioner Connection Material: CS, CS A105, PP, SS304, or SS316

- Process Connection: ¾” or 1” or 1‐1/2” NB ASME 150# flange

- Pointer Material: Red powder-coated CS or SS304 (pointer height = 60 mm for 7.5 meters range and 80 mm for 15 meters range)

- Pointer Travel: Full for ground level, elevated tanks, and underground tanks (< 4 meters), Half for underground tanks from 4 to 8 meters depth

- Pull Chain: Nylon rope with PP handle for highly viscous liquids which tend to solidify at ambient temp.

- Alarm Switches: Micro switch, mono‐stable, SDPT x ABS enclosure IP65, Switch rating‐ 5A, 250VAC One to four numbers (max)

- Accessories: Counter flanges (CS), nuts, bolts (CS), & CAF gaskets, measuring/guide nozzles with flange (CS), nuts, bolts (CS), & CAF gaskets.

Maintenance

Regular inspection is crucial to maintain the proper functioning of the gauge. The float should be wiped clean to remove any sediment particles and visually inspected for any damages.

During maintenance, it’s important to ensure that the switch enclosure cover is properly fitted with its gasket to ensure ‘IP66’ weatherproofing.

When detaching the measuring rope from the elbow pulley, it’s necessary to check the movement of the pulley by removing the pulley cover and making sure that it rotates smoothly around its shaft.

It’s essential to check for wear and tear and clean the pulleys if required.

Installation of Float and Board Tank Level Gauge

A gauge board mounted on the side of a ground-level tank with full travel capability is shown in the below image.

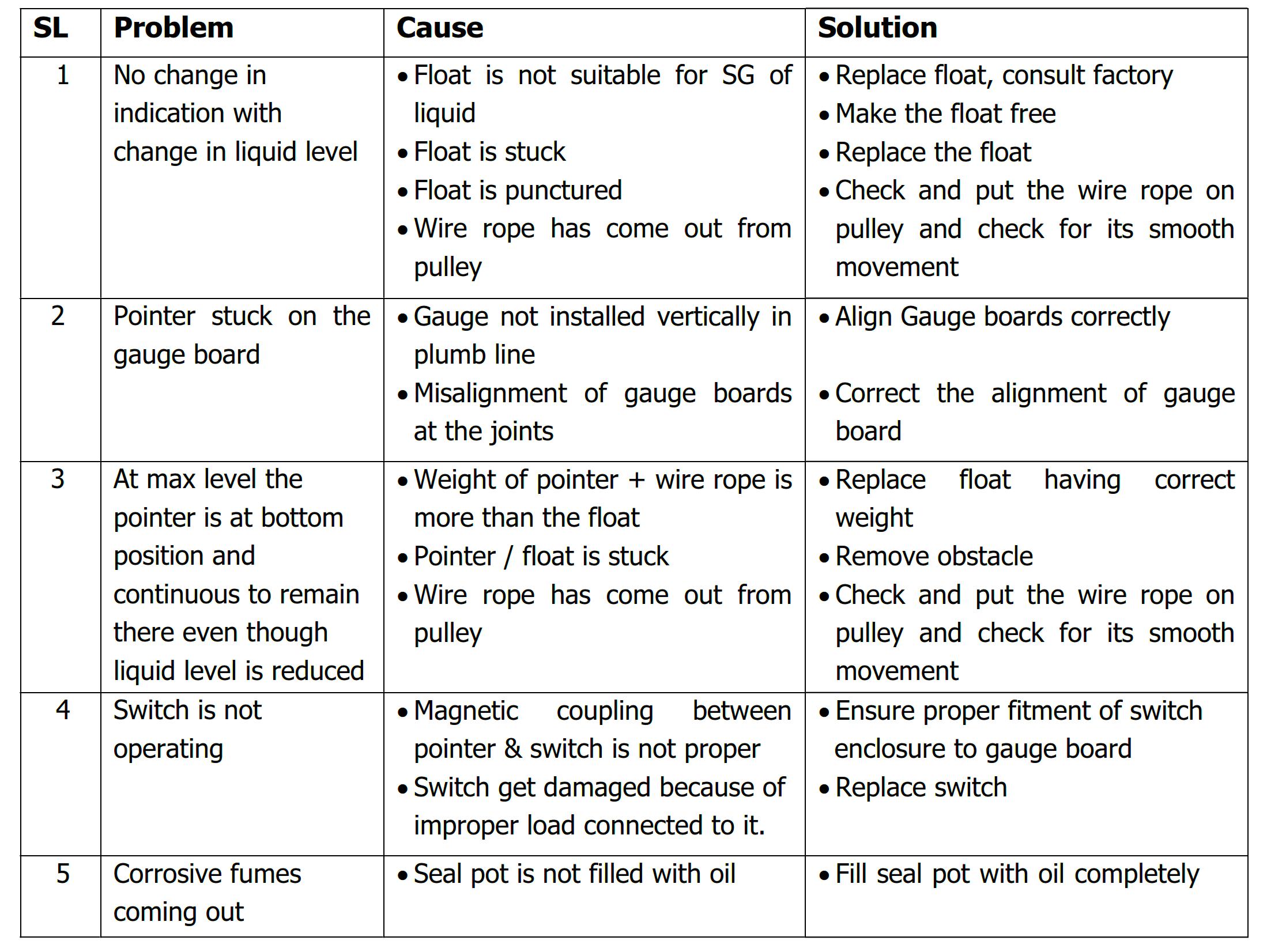

Troubleshooting Float & Board Tank Level Gauges

Some of the most common problems and solutions are mentioned below.

Location

Report abuse

Report abuse

Featured