Magnetic Float Guided Level Switch – Pune Techtrol

Description

Magnetic Float Guided Level Switch is used to detect the liquid level in open or pressurized tanks. It is available as a single or multiple-point switch and is designed to work efficiently in a wide range of liquids, including conductive, non-conductive, and corrosive liquids.

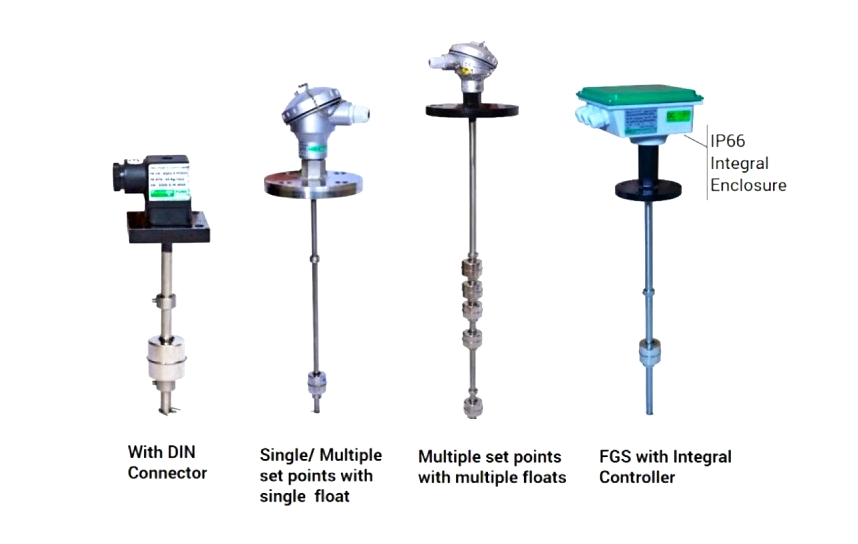

Magnetic Float Guided Level Switch

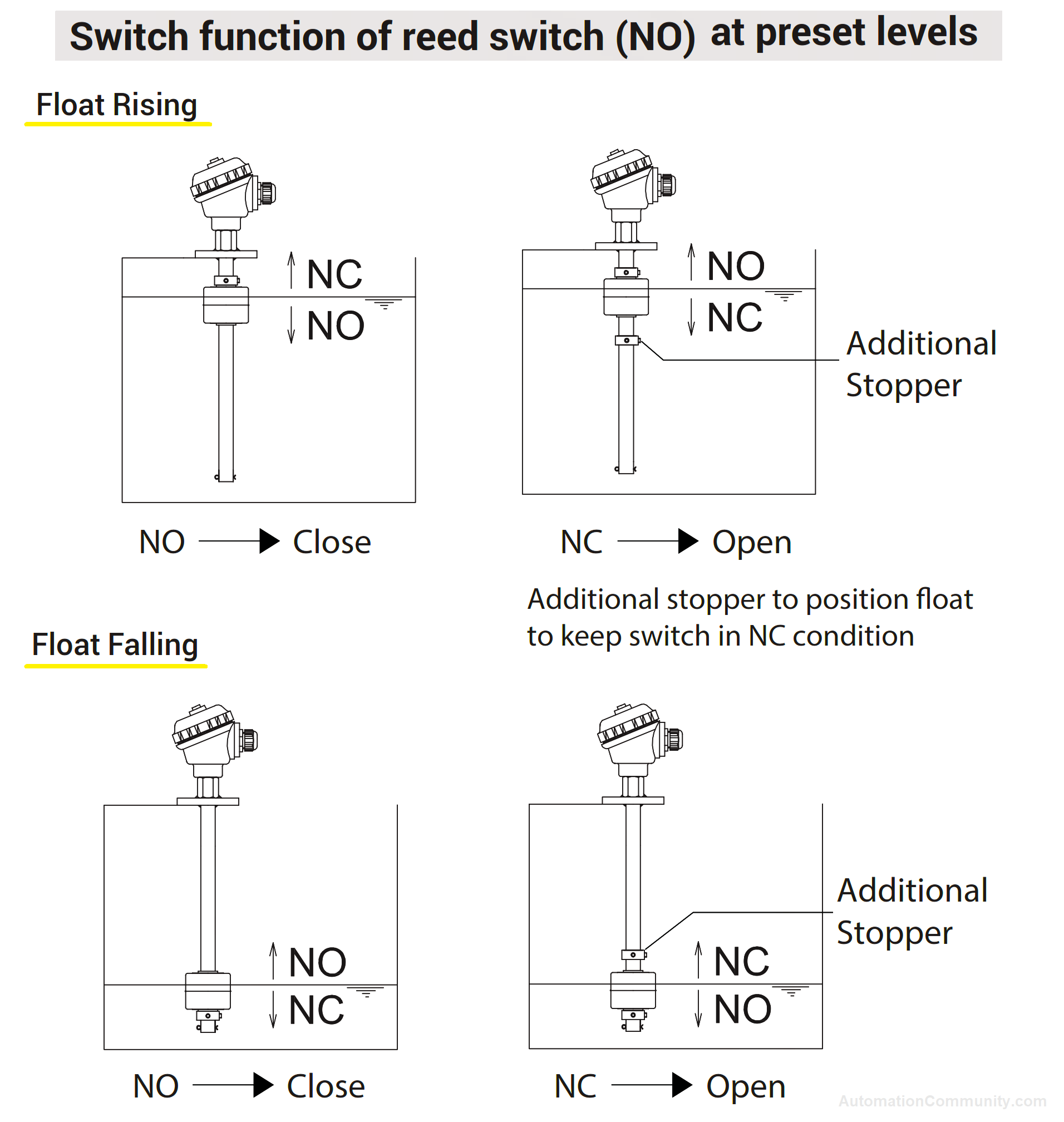

The Magnetic Float Guided Level Switch comprises a magnetic float that moves on a guide tube, which houses reed switches that are hermetically sealed at preset levels. The float follows the liquid level and magnetically actuates reed switches at preset levels, causing a changeover of contacts. Single or multiple switching is achieved through single or multiple floats as required by the application.

The switch is available in two variants – FGSO, which is fitted with a weatherproof or flameproof enclosure, and FGSI, which is fitted with a plug-in connector or epoxy potted cable.

Zener Barrier can also be provided for intrinsic safety. The switch’s low-power potential-free reed contacts can be directly connected to PLC, DCS, or SCADA, and their contact rating can be amplified to SA, 250VAC, through the use of a controller (TLC-F) for driving higher load devices.

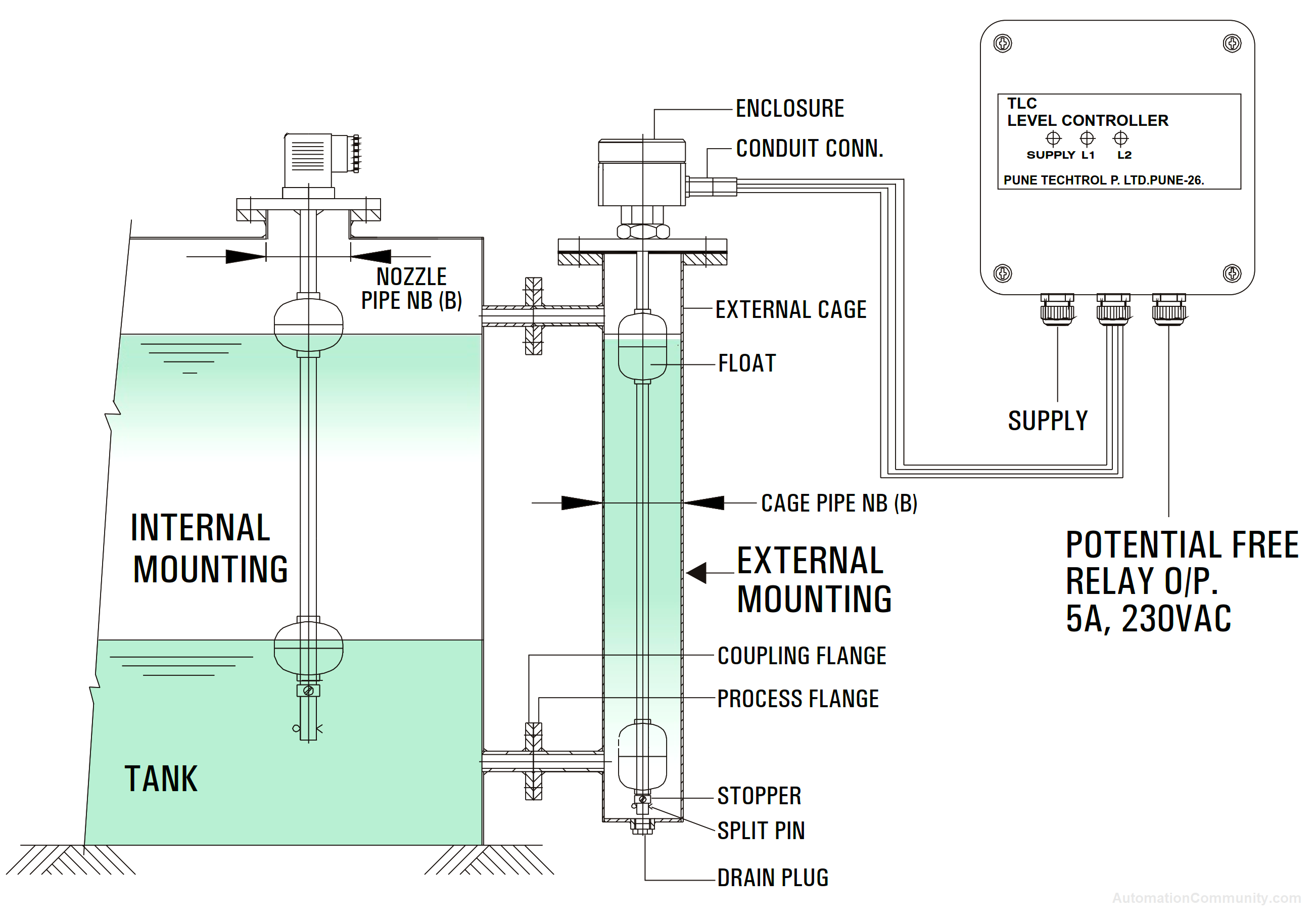

The Magnetic Float Guided Level Switch is suitable for detecting liquid levels in tanks and can be installed internally or externally. It requires minimal maintenance and is commonly used for high and low alarms in process tanks, water treatment and filtration systems, and pump and cooling circuit protection.

Magnetic Float Guided Level Switch Specifications

FGSO Model

- Range: upto 3000mm

- Wtd Parts: SS304/316, PP or PVDF

- Max. Temp: 150ºC

- Max. Pressure: 10 Kg/cm2

- Liquid Density: ≥0.6 g/cm3

- Contacts: 40VA (NO), 60VA(C/O)

- Enclosure: IP66 or Ex-P Gr IIB or IIC

- Options: Intrinsically Safe, Small /Large/Multiple Floats, In-Situ Test Device

FGSI Model

- Range: upto 1000mm

- Wtd Parts: SS304/316

- Max. Temp: 100ºC

- Max. Pressure: 10 Kg/cm2

- Liquid Density: ≥0.6 5g/cm2

- Contacts: 40VA (NO), 60VA(C/O)

- Termination: Flying Leads, Plug-in Connector

- Options: Intrinsically Safe

Installation of Magnetic Float Guided Level Switch

To install the Magnetic Float Guided Level Switch, follow the below procedure:

- Choose a suitable location on the tank where vibrations are minimal.

- Ensure that the liquid in the tank does not contain excessive contaminants that may inhibit float operation.

- Ensure that the internal diameter of the mounting nozzle is larger than the diameter of the float.

- If the float diameter is greater than the nominal bore, remove the float from the guide tube and reinsert it from the bottom of the guide tube after installation.

- Make sure that the process connection of the level switch matches that on the tank.

- In the case of an externally mounted version, ensure that the center-to-center distance of the external cage matches that of the tank.

- In the case of an externally mounted version, provide a separate isolation valve on the tank for safety and removal of the level switch for repairs or maintenance.

- Ensure that the internal diameter of the tank mounting nozzle allows its insertion without float removal and its length allows switch operation at the desired preset level.

- Provide a suitable gasket between the flanges and appropriate thread sealant between threads before bolting/tightening to ensure zero leakage through joints.

Magnetic Float Guided Level Switch Maintenance

Maintenance of the Magnetic Float Guided Level Switch is important to ensure its proper functioning.

Here are some steps for maintenance:

- Wipe the float and guide tube to remove any deposits or scaling formed on them.

- Clean the switch frequently if the liquid is highly viscous or contains floating material.

- Check and tighten any loose terminal or stopper screws.

- Visually examine the float for any punctures, and check the guide tube for bending or other damage.

- After maintenance, make sure to close the enclosure with its protective cover and gasket to ensure waterproofness (IP66).

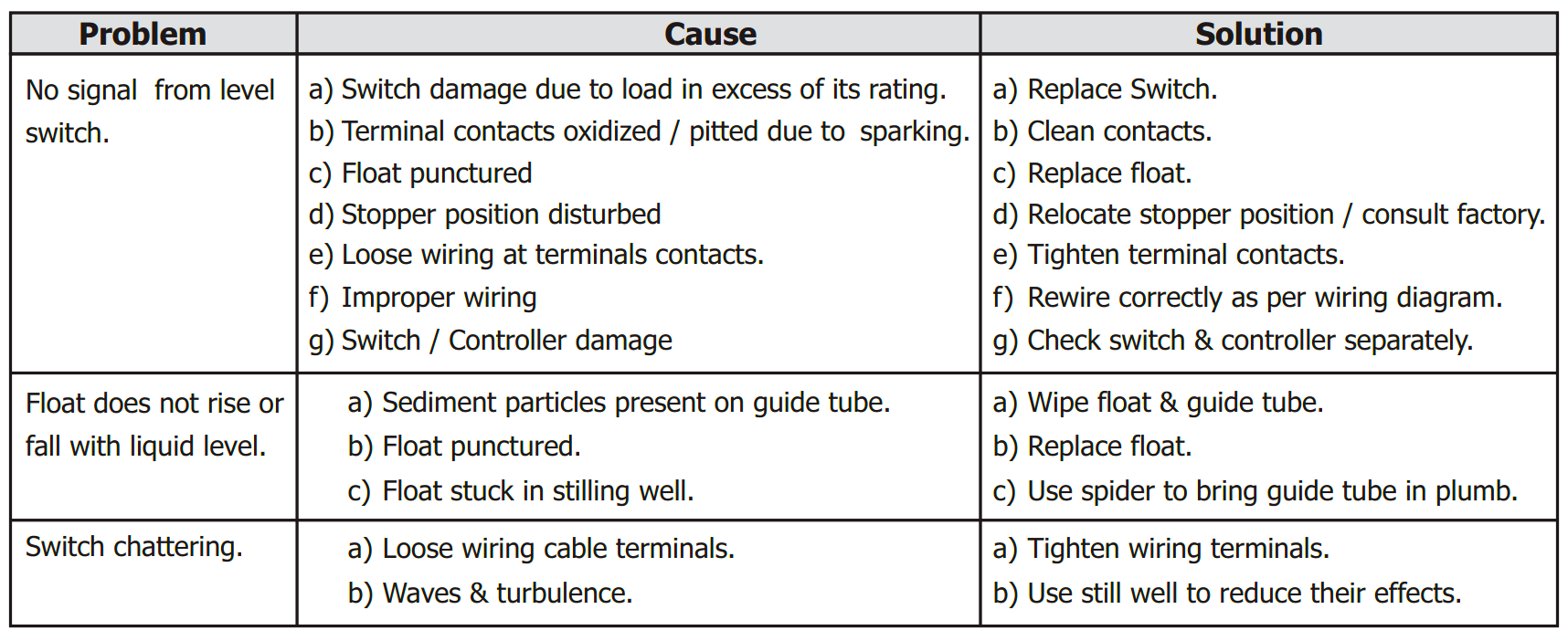

TroubleShooting Magnetic Float Guided Switch

Some of the problems and solutions of Magnetic Float Guided Level Switches are mentioned below.

Video

Location

Report abuse

Report abuse

Featured