Displacer Type Magnetic Level Switch (DS) – Pune Techtrol

Description

The Displacer Type Magnetic Level Switch operates using the buoyancy principle and is an effective solution for measuring liquid levels. These sensors are highly versatile and come with various alarm and control options, making them suitable for a wide range of applications, regardless of their complexity.

Displacer Type Magnetic Level Switch

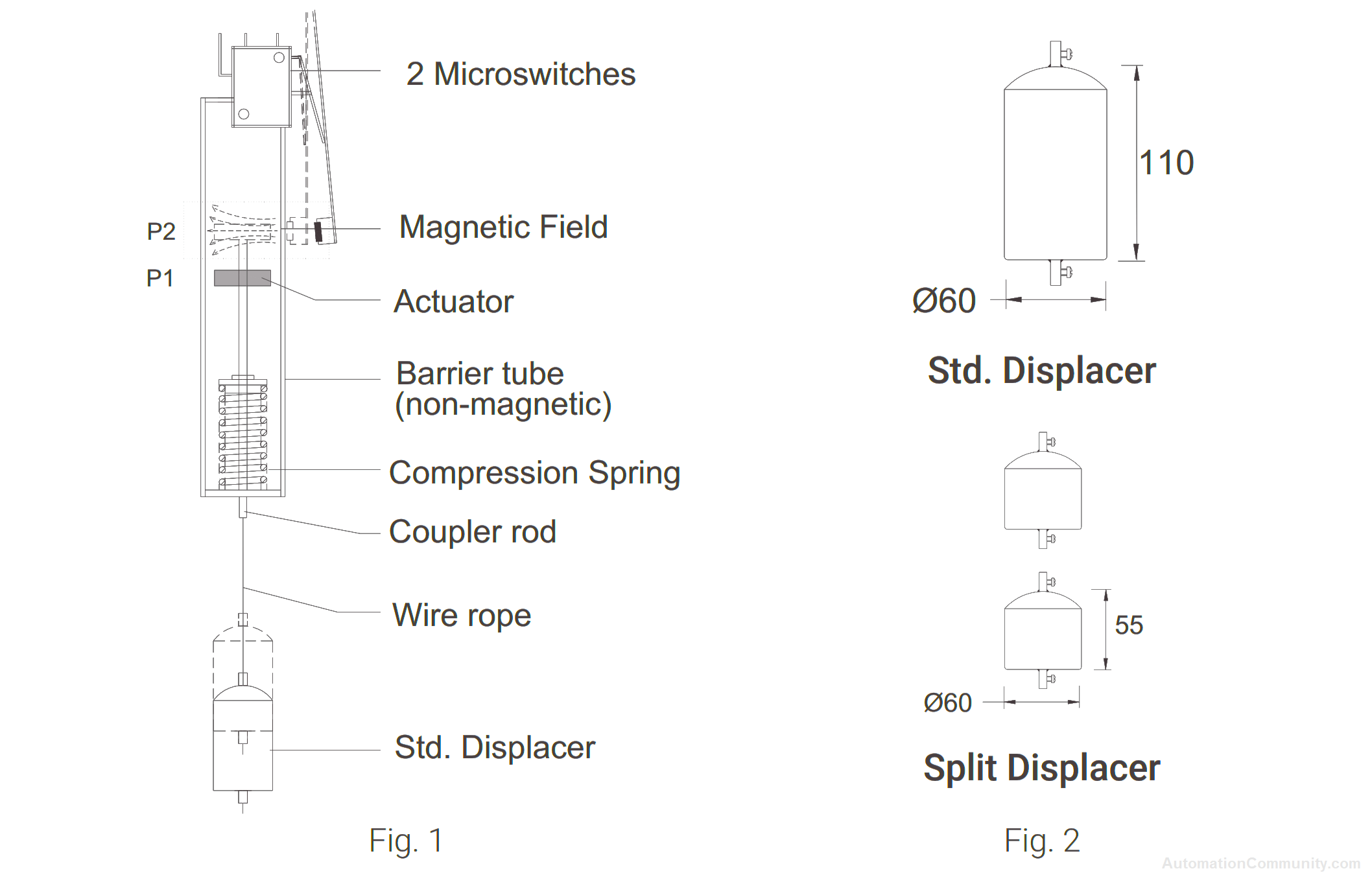

The working principle of a Displacer Magnetic Level Switch involves the suspension of one or two split displacers from a wire rope, which are then connected to a coupler rod.

This rod carries an actuator that moves within a nonmagnetic barrier tube via a compression spring, as shown in Figure 1.

Initially, when the displacer is not immersed in liquid, the spring is compressed due to the weight of the displacer, and the actuator is positioned outside the magnetic field at position P1. As the liquid level rises, the displacer becomes immersed, causing it to undergo weight loss according to Archimedes’ principle. This results in an upward motion of the coupler rod, which allows the spring to assume its original status and move the actuator to position P2 within the magnetic field.

When the actuator moves to P2, it triggers the micro switches, resulting in changeover contacts that provide an indication of the liquid level. This mechanism makes Displacer Type Magnetic Level Switches highly effective at accurately measuring liquid levels.

Precautions During Installation

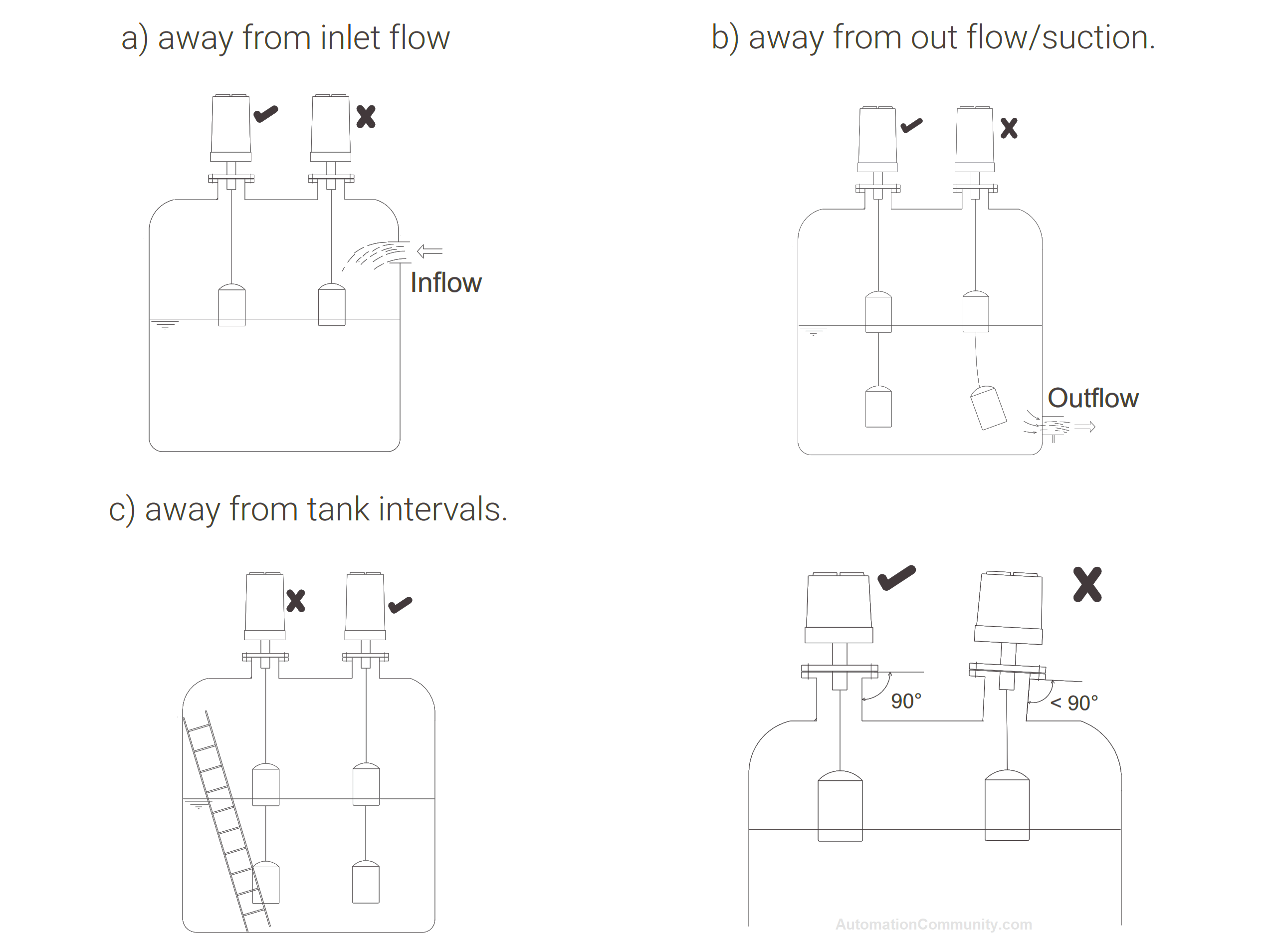

When installing a Displacer Type Magnetic Level Switch, it’s important to take certain precautions to ensure accurate measurement and proper functioning.

These precautions include:

- Ensuring proper location for the switch installation.

- Locating vibration devices such as pumps and generators far away from the tank to avoid any interference.

- Making sure that the tank nozzle is perpendicular to the tank top so that the installed switch is in plumb.

- Ensuring that the PCD (pitch circle diameter) of the process and nozzle flange match.

- Providing a suitable gasket between the flanges to prevent any leakage through the joints.

- Ensuring that the lowest displacer does not touch the tank bottom, keeping it at a distance of 40 to 50mm above the bottom.

- Winding the excess wire rope on the lowest displacer to prevent any interference with the liquid level measurement.

Installation of Displacer Level Switches

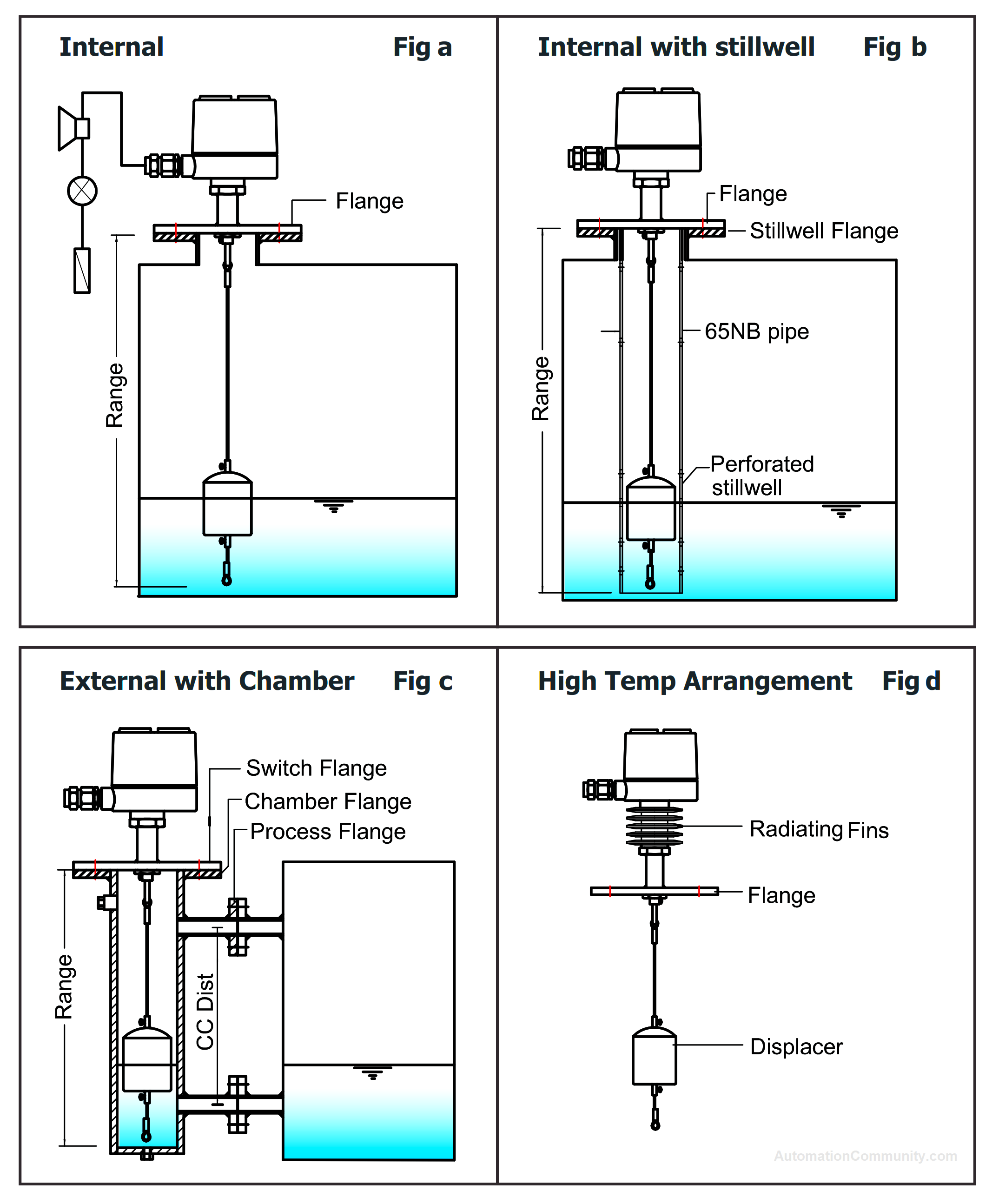

Displacer Level Switches offer a variety of installation options to suit different tank configurations and applications.

These installation options include:

- Internal installation without a Stillwell, as shown in Figure a.

- Internal installation with a stillwell for tanks that experience turbulence, as shown in Figure b.

- External installation in a chamber to overcome limited space within the tank or where mechanical devices such as stirrers operate, as shown in Figure c.

Choosing the right installation option is essential to ensure accurate measurement and reliable performance of the Displacer Type Magnetic Level Switch. By selecting the appropriate installation method, one can effectively monitor liquid levels and prevent any potential issues related to tank overfill or underfill.

Maintenance of Displacer Magnetic Level Switch

Maintenance of a Displacer Type Magnetic Level Switch is essential to ensure accurate measurement and reliable performance.

The following maintenance steps should be followed:

- Switch off the power supply before commencing any maintenance or repair work on the switch.

- Dismount the switch and clean the displacers to remove any deposits or scaling that may have formed on the surface.

- Ensure that all terminal connections are properly tightened.

- Check the contact terminals to ensure that they are not pitted or oxidized.

- Inspect the wiring cable insulation for any signs of brittleness or breakage and replace if necessary.

- In hazardous locations, open the enclosure only after disconnecting the switch from the power supply to prevent explosions.

- After completing maintenance, ensure that the enclosure cover is screwed back on with its gasket to ensure weatherproofness.

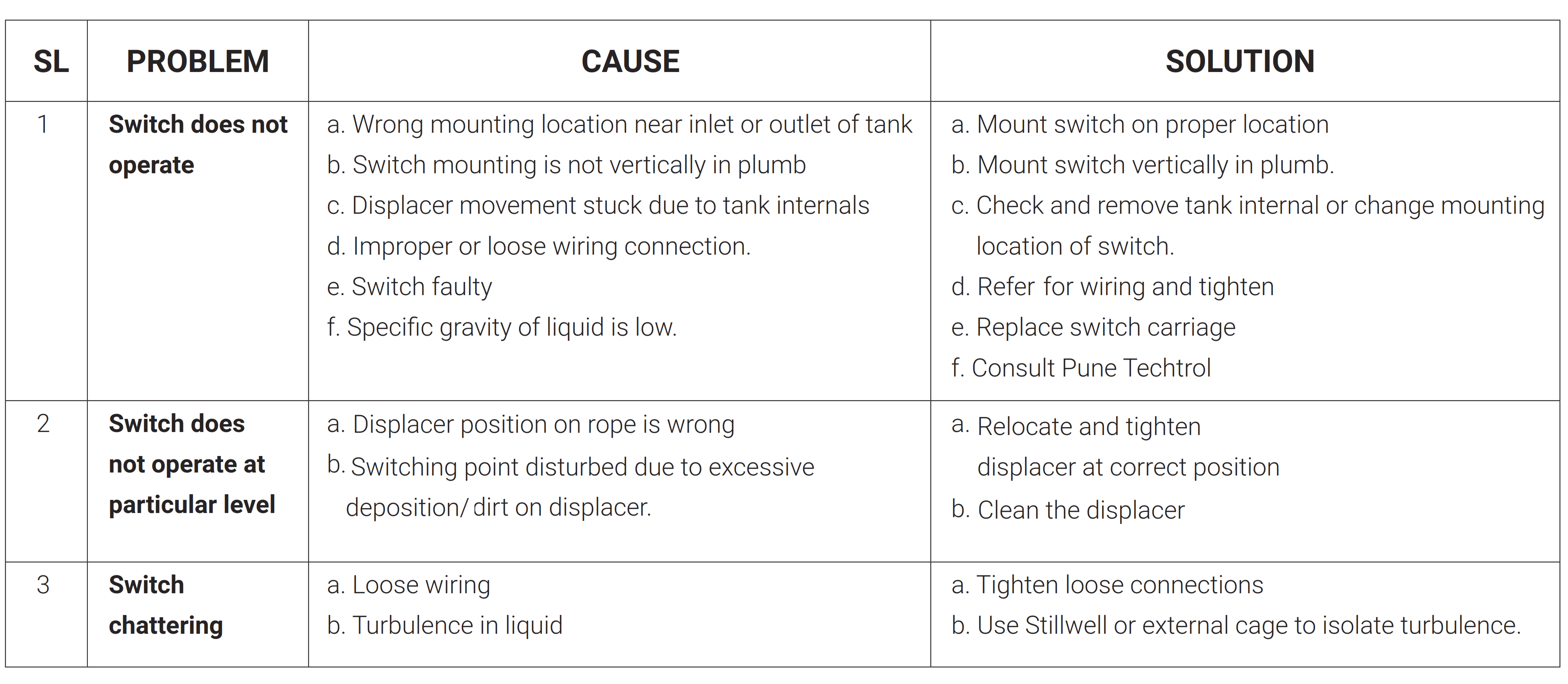

Troubleshooting Displacer Magnetic Level Switch

Some of the common problems and solutions of Displacer Magnetic Level Switches are mentioned below.

Video

Location

Report abuse

Report abuse

Featured