Rotary Paddle Level Switch for Solids (RPLS) – Pune Techtrol

Description

The Rotary Paddle Level Switch is designed to detect the level of free-flowing solids or bulk materials and alert users in the event of a disruption in their continuous flow.

Rotary Paddle Level Switch

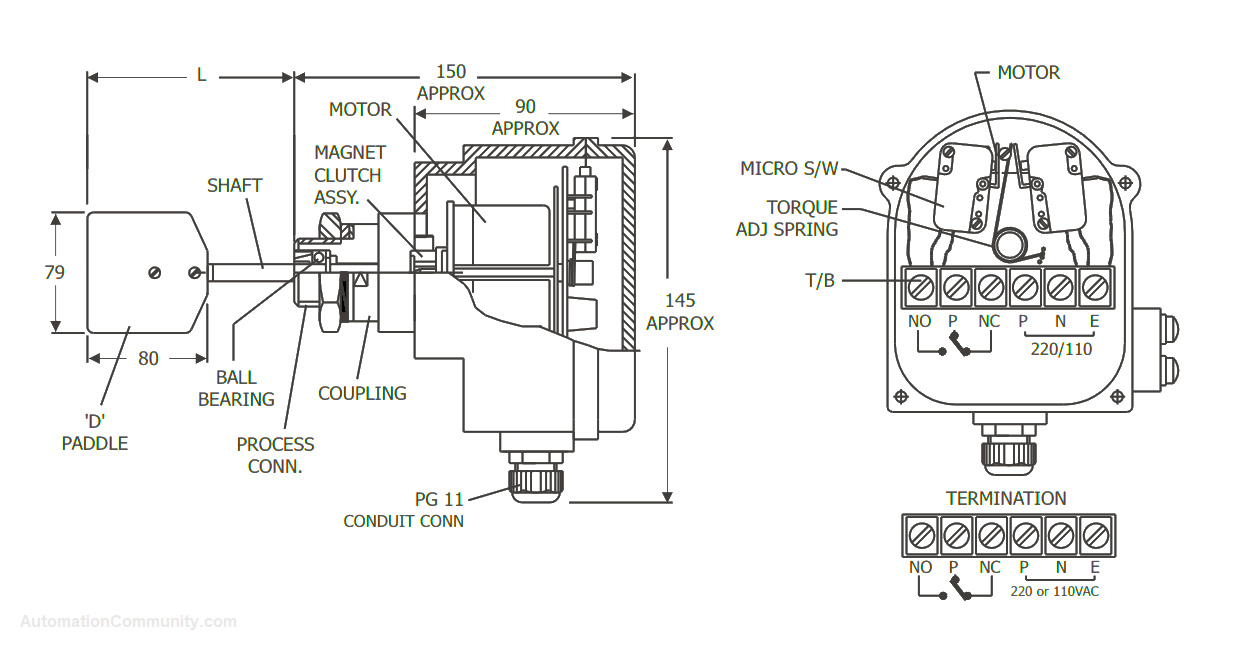

The Rotary Paddle Level Switch includes a synchronous motor, micro switches, and a torque-adjusting mechanism, all housed in an enclosure. The motor powers a paddle that rotates at a low speed, allowing it to rotate freely when it is not in contact with the material.

When the material level rises and comes in contact with the paddle, the paddle is held in place, stopping the motion and generating a reaction torque that triggers the two micro switches.

One switch disengages the motor from the power supply, while the other sends an output signal for the required control action. When the level of solids drops, the paddle is released, causing the micro switches to reverse their action and the motor to restart.

By selecting the appropriate paddle and using the torque adjusting mechanism, the torque can be adjusted to match the bulk density of the material.

Installation of Rotary Paddle Level Switch

Installation Procedure:

- The switch is suitable for indoor/outdoor installation.

- Check that the tank pressure and temperature are within the permissible limits/rating.

- Ascertain whether a “High Level” or “Low Level” switch is required and preset the switching point accordingly.

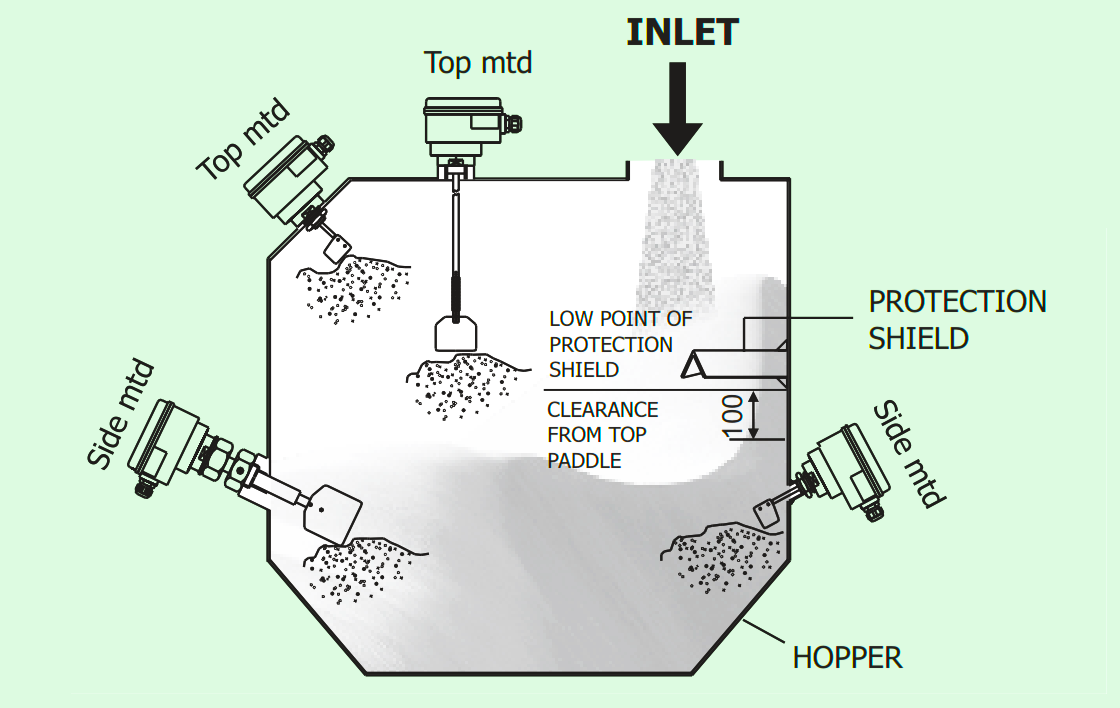

- Determine the location of the tank, taking into account the flowing and arching properties of the material (angle of repose).

- For high-level switching, mount the switch from the top vertically, horizontally, or at an angle, ensuring that the paddle comes in full contact with the material to sense the switching point.

- For low-level switching, mount the switch from the side horizontally or at an angle, ensuring that the residual material (dead stock) sticking to the tank walls does not give a spurious signal.

- If the tank opening is too small for switch insertion, remove the paddle and mount the switch. Reassemble the paddle after mounting.

Specifications of Rotary Paddle Level Switch

- Power Supply: 110 or 220VAC ±10% (50~60Hz) or 24VDC

- Power Consumption: 3.5 VA

- O/P Contact Rating: 5A, 250VAC (1SPDT) / (2SPDT)

- LED Indication: Red/Green to indicate power ON-OFF/Level status

- Rotary Speed: 1RPM

- Sensing Torque: 3 Kg-cm

- Temperature: -10 to 80°C (Std) -10 to 150°C (High Temp)

- Process Connections: 1″ BSP (M) Screwed or 3½” NB, ANSI 150# Flange

- Installation: Side / Top / Angular

- Paddle Type: ‘S’ – Bulk Density more than 1kg, ‘D’ – Bulk Density 700 gm to 1 kg, ‘F’ – Bulk Density 700 gm to 1 kg (can be folded down for insertion in small bore vessels), ‘C’ – Bulk Density 500 gm to 700 gm

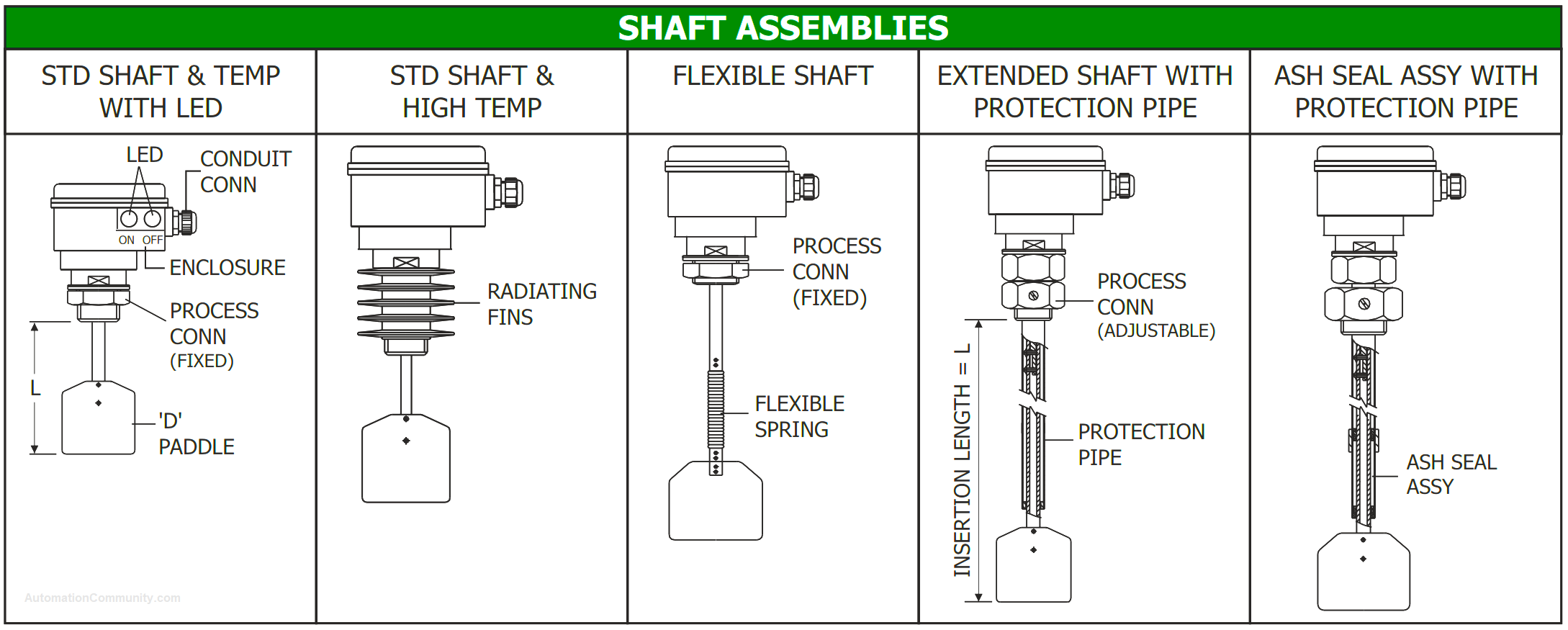

- Insertion Length (standard shaft): L–73mm (‘S’ Paddle ), 118mm (‘D’ & ‘C’ Paddles), 200mm (‘F’ Paddle)

- Insertion Length (with protection pipe): L=200 to 1500mm

- Pressure: Atmospheric

- Flexible Shaft: L=210mm ( ‘D’ & ‘C’ Paddles) (with SS spring) L=170mm (‘S’ Paddle)

- Enclosure: Cast Al x IP-65 or ABS x IP65

- Cable Gland: PG 11, Polymide

Rotary Paddle Level Switch Shaft Assembly

The types of shaft assemblies for rotary paddle level switches are mentioned below.

Troubleshooting of Rotary Paddle Level Switch

If the rotary paddle level switch is not rotating despite the supply being on, follow these troubleshooting steps:

- Check if the wiring is correctly done as per the Wiring Diagram and if the termination is not loose.

- Ensure that the cable is not damaged and none of its core wires are open.

- Check if there is any foreign material that is interfering with the motion of the paddle.

- Check if the motor shaft is not damaged and is straight, to allow the paddle to rotate.

- Ensure that the bearing is working smoothly and is not impaired by any material.

- If the “Supply Micro Switch” is found to be faulty, repair or replace the micro switch.

- If the paddle still does not rotate after ensuring the above steps, it may be necessary to repair or replace the motor.

If the paddle rotates at the preset level when in contact with the material, the following steps can be taken:

- Reset or increase the torque by adjusting the torque setting mechanism if the paddle is rotating at the preset level in contact with the material.

- Change the paddle size to generate sufficient torque.

- Extend the shaft length to reach the material level.

- After ensuring the above steps, if the paddle still rotates, contact the manufacturer or supplier for further assistance.

If the output micro switch does not operate at the preset level, although the paddle is not rotating, the following troubleshooting steps can be taken:

- Ensure that the switch body is not loose.

- Check that the hinge levers of the micro switch are not bent or damaged.

- Verify that the micro switch contacts are not damaged or burnt.

- Ensure that there is no slippage of the magnetic clutch.

- If the above steps do not solve the problem, the magnet or micro switch may need replacement.

Location

Report abuse

Report abuse

Featured