Vibrating Fork Point Level Switch for Liquids – Pune Techtrol

Description

A vibrating Fork Point Level Switch uses piezo-driven vibrating fork technology to detect the presence or absence of liquids in tanks. It is specifically designed for point-level detection and is ideal for applications where reliable and accurate liquid-level monitoring is required.

Vibrating Fork Point Level Switch

The Vibrating Fork Point Level Switch is available in two different versions, the Integral (Standalone) and Two Part system. The Integral system has a controller integrated with the sensing probe, while the Two Part system has a separate controller that can be mounted remotely.

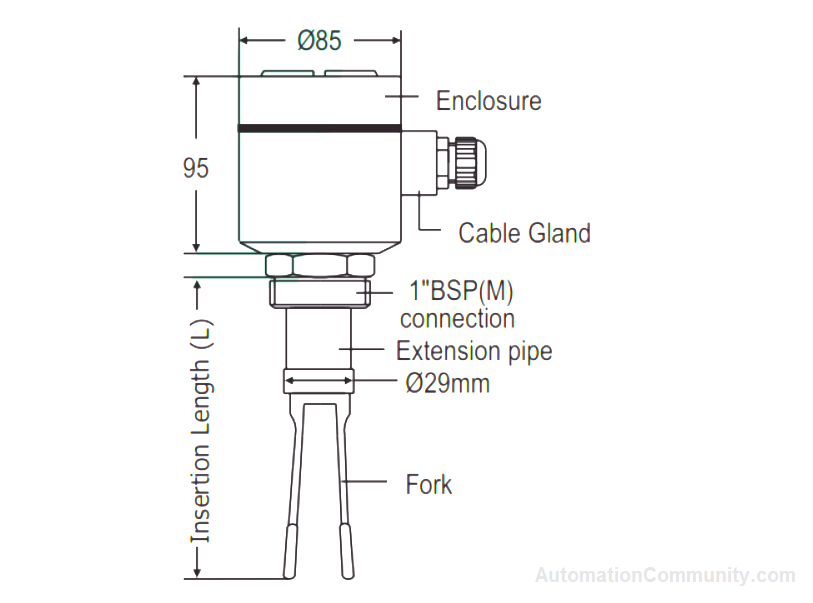

The sensing probe is constructed to be rugged, and it is equipped with an enclosure at its top end to hold the control electronics. At its lower end, the probe holds a SS tuning fork that vibrates at its mechanical resonance frequency of 400 Hz, created through a piezo crystal when in the air.

However, when the tuning fork is covered with liquid or slurry, its vibrations get damped, which is then sensed by the control electronics. This leads to a change in the status of the output relay contacts.

Applications

“The Vibrating Fork Point Level Switch is a versatile device that can be used to detect all types of liquids, as well as various materials in the plastic industry such as powders and granules. It is also suitable for detecting light and free-flowing powders.”

Specifications

- Insertion Length: 125 to 2500mm

- Wtd Parts: SS304/316

- Max. Temp: 150ºC

- Max. Pressure: 10 Kg/cm2

- Density: ≥0.5Kg/m3

- Output: 5A, 250VAC x DPDT

- Enclosure: Cast Al x IP66 or Ex-P IIB

- Options: Integral, Two-part

Installation

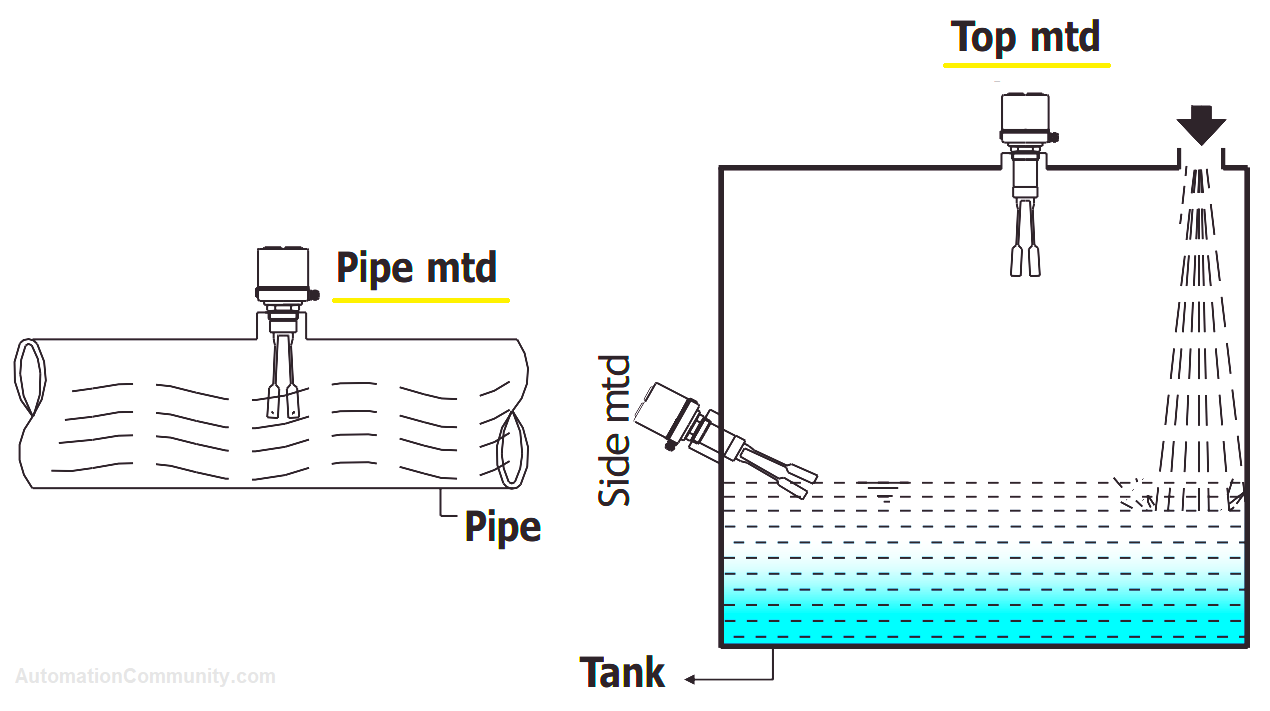

The Vibrating Fork Point Level Switch can be side-mounted on the container wall or from the tank top. When side-mounted, the fork tines should be horizontally or pointed slightly downward to ensure proper functioning. It is also important to ensure that the switch is mounted at the desired level of the material to be controlled.

Precautions

To ensure proper installation of the Vibrating Fork Point Level Switch, several precautions should be taken. These include making sure that the fork tines are not bent or distorted and that materials do not fall directly onto them during filling operations.

When installing the probe with screwed mounting, it’s important to turn the hexagonal mounting nut of the probe instead of the housing. For side mounting, the tines should be positioned in a way that allows the material to flow freely through them, and their knife edges should face the ground plane in horizontal mounting positions.

It’s also important to ensure that the tines extend far enough into the vessel to vibrate freely despite any build-up on the vessel wall, without extending further than necessary. Shielding the tines with a windscreen can prevent operational problems caused by turbulence during pneumatic conveying.

If the electronics switching unit/controller is mounted remotely, the probe connection cable gland of the Cast Aluminum housing of the Switching unit should point towards the ground plane.

Calibration of Vibrating Fork Level Switch

The Vibrating Fork Switch with an integral controller comes equipped with a DIP switch, with the following functions: SW1 – S/L: NA – should be OFF; SW2 – FSS: Fail Safe Switch+; SW3 – OND: On-time delay settings; SW4 – OFD/CAL: Off-delay settings and calibration.

For the two-part system, a push switch for fail-safe high and low selection is provided, and calibration is not required. While all switches are usually calibrated at the factory, it may be necessary to calibrate the switch.

To calibrate the switch for liquid applications, ensure that the instrument is switched off. Dip the fork blades in liquid, ensuring that only approximately 30% of the blades are submerged. Switch on the 4th DIP switch and power on the instrument, and the red LED will blink five times.

During calibration, the fork blades should not be moved and should be fixed at 30%. After five LED blinks, switch the 4th switch to OFF condition, and the calibration is complete. Finally, check the functioning of the instrument.

Maintenance

Maintenance of the Vibrating Fork Point Level Switch involves periodic cleaning of the tines if there is a tendency for the material to build up over time. It is important to ensure that the cable glands and housing lid are properly sealed to prevent moisture from entering the switch.

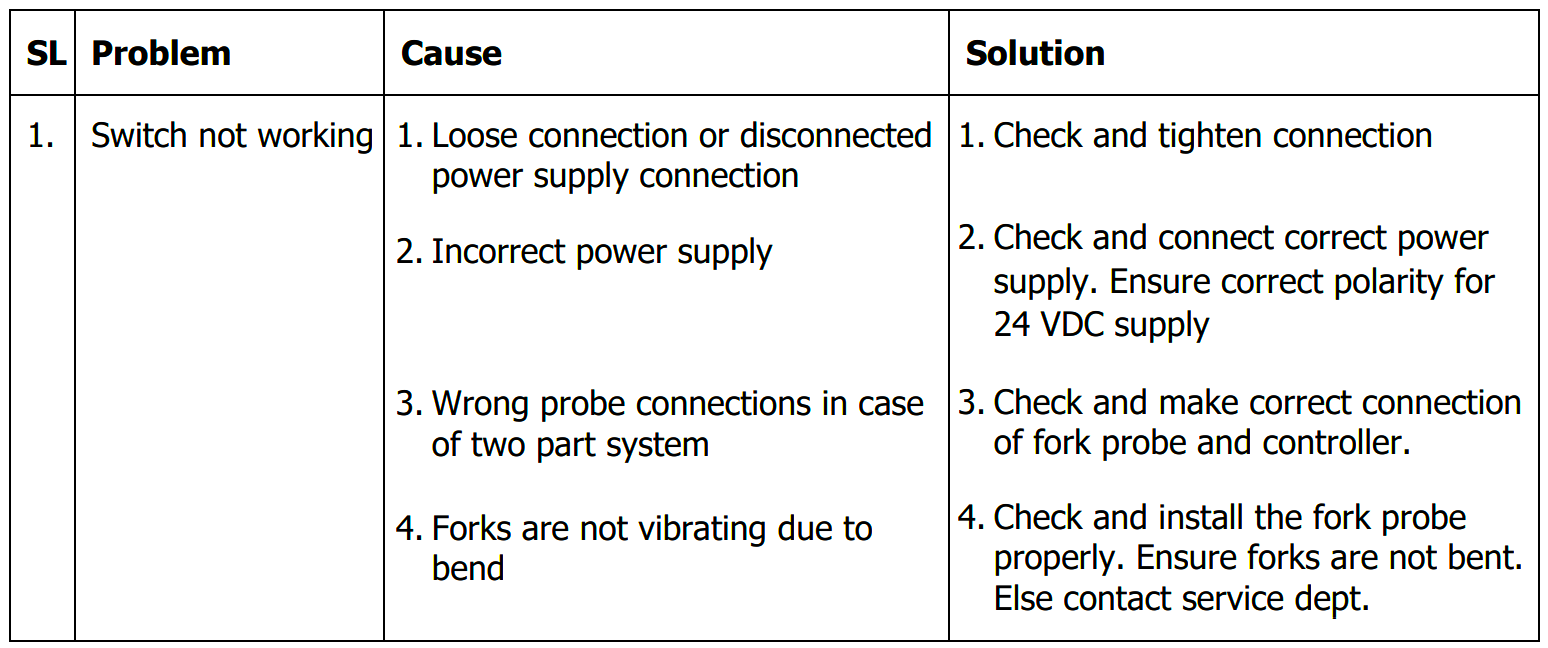

Trouble Shooting Vibrating Fork Point Level Switch

Some of the common problems and solutions of Vibrating Fork Point Level Switches are mentioned below.

Location

Report abuse

Report abuse

Featured