Vibrating Fork Level Switch for Solids (VFSS) – Pune Techtrol

Description

The vibrating fork level switch (VFSS) uses piezoelectric-driven vibrating fork technology, and it has been specifically designed to detect free-flowing powders, grains, and granular solids in bins, silos, or hoppers.

Vibrating Fork Level Switch

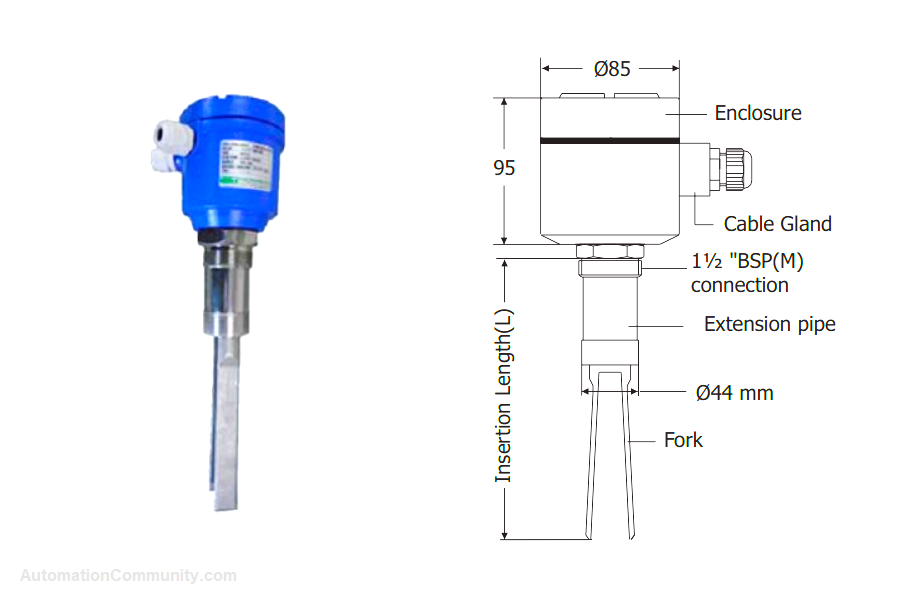

The Vibrating Fork Point Switch is a versatile point-level switch available in two versions – Integral (Standalone) and Two Part. The Integral system integrates the sensing probe and controller, while the Two Part system separates the controller from the probe for remote mounting. With rugged construction, the sensing probe is offered in standard and high-temperature designs. It features an enclosure at the top end to house the control electronics, while the bottom end has a stainless steel tuning fork.

The piezo crystal within the tuning fork causes it to vibrate at a frequency of 120 Hz when exposed to air. However, if covered by solid material, the vibrations are dampened, which is detected by the control electronics. This results in a change in the output relay contact status, allowing for the accurate detection of free-flowing powders, grains, and granular solids in a variety of industries, including building materials, food, plastics, and mining.

Applications of Vibrating Fork Level Switch

The Vibrating Fork Point Switch has various applications across multiple industries. It can be used to detect building industry materials such as cement, sand, and lime, as well as foodstuff industry items like milk powder, flour, salt, and food grains.

It is also useful in the plastic industry to detect powder granules and in the timber industry, chemical, and mining sectors, among others.

Operation

The Vibrating Fork Point Switch relies on electronically stimulated fork technology to vibrate at a mechanical resonance frequency of roughly 125Hz. When bulk material covers the fork, its vibrations are electronically dampened, and the corresponding signal is triggered.

The fork’s vibration has a self-cleaning feature, which means that even light deposits on the container wall will not impact its performance.

Vibrating Fork Level Switch Specifications

Sensing probe

- Enclosure: Cast Al, WP -IP 66, Cast Al, Ex-Proof Gr. IIB

- Conduit Connection: Polyamide PG 16 x W-Proof Const. Brass 3/4″ ET x Ex-Proof

- Mounting: SS304 x 1½” BSP (M) screwed

- Fork MOC: SS316

- Extension Pipe MOC: SS304 or SS316

- Standard Insertion Length (L): 250 mm

- Max Insertion Length (L): 2500 mm

- Resonance Frequency: 120 Hz

- Max Temperature: 150°C/200°C (With temp standoff)

- Max Pressure: 10Kg/cm2

- Particle Size: Max 10 mm

Controller (Integral)

- Enclosure Dimensions: Ø120 x 165 height

- Conduit connection: Polyamide PG 16 x 2 Nos

- Supply: 110 or 230 VAC 50-60 Hz or 24VDC

- Relay Contacts: DPDT x 5A, 230 VAC resistive load

- Signal Delay: Fork covered to free about 2-3 secs. Fork free to cover 2 secs.

- Switching Delay: Continuously adjustable from 2 to 20 secs for fork free or covered

- Safety Operation: Field selectable fail safe high & low

- LED Status Display: Power ON-Yellow; Normal-Green; Alarm-RED

- Power Consumption: 2VA

- Amb Temperature: 60ºC

- Amb Humidity: 95% Rh noncondensing

Controller (Two-part) All specs as in Integral except

- Enclosure Dimensions: Ø122 x 150 height

- Interconnecting Cable: 3 core x 1.5mm2 PVC Insulated (Buyer’s Scope)

Installation of Vibrating Fork Level Switch

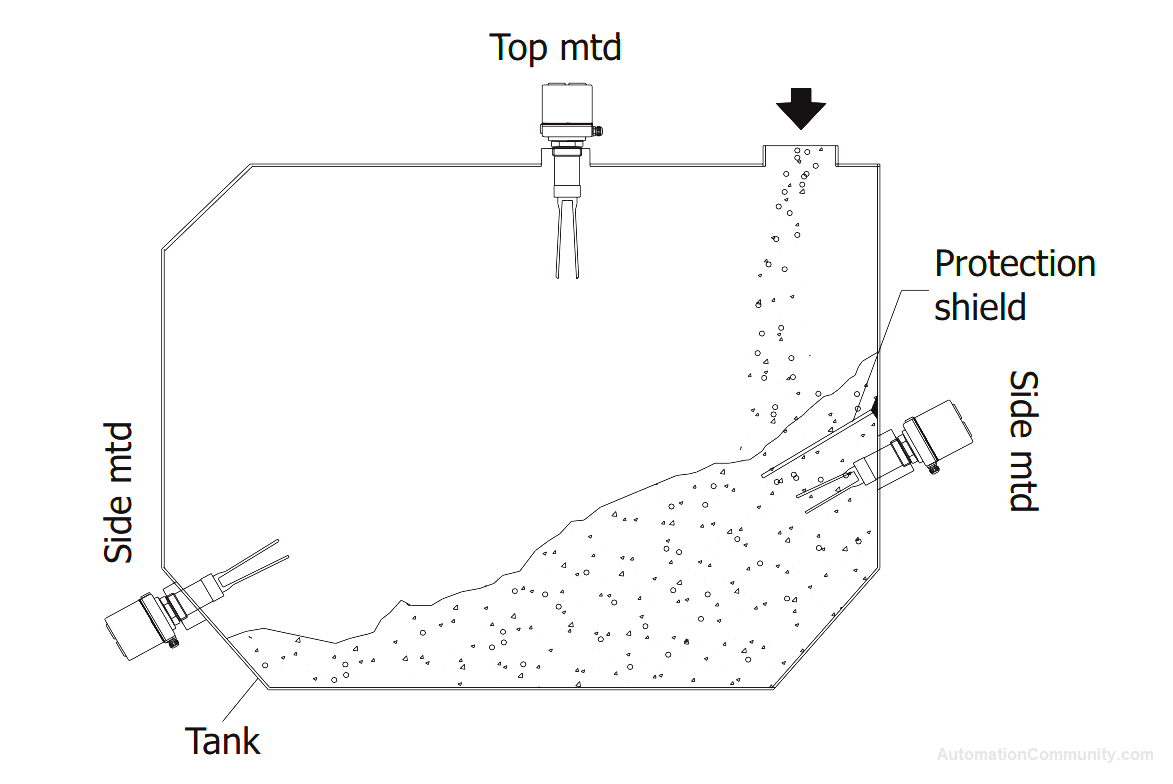

The standard unit of the Vibrating Fork Point Switch can be laterally mounted on the container wall using screwed mounting at the desired level of material control. The fork tines should either be horizontal or slightly pointing downwards.

During installation, it is important to avoid bending or distorting the tines. If the material falls directly on the tines during filling operations, a protective shield must be used.

When installing the probe using screwed mounting, the hexagonal mounting nut should be turned, not the housing. For side mounting, the tines should be positioned in a way that allows the material to flow freely through them. The knife edges of the tines should face the ground plane when horizontally mounted.

The tines should extend far enough into the vessel to vibrate freely, despite any build-up on the vessel wall. It is also important to mount the extended probe no further than necessary in the vessel. Turbulence during pneumatic conveying can cause operational problems, which can be prevented by shielding the tines with a windscreen.

If remotely mounting the Electronics Switching unit, the probe connection cable gland of the Cast Aluminium housing of the Switching unit should face the ground plane.

Fail Safe Mode

The Vibration Switch offers the flexibility to select either minimum or maximum fail-safe modes based on the process requirement. By default, the relay is energized in the Vibration Switch. However, when the level changes state, the relay gets de-energized.

Therefore, not only does the operator receive an alarm during level alarm conditions but also during instances of instrument failure or mains failure, thereby enhancing the overall reliability of operation. In maximum fail-safe mode, the relay de-energizes when the level surpasses the desired level or when there is a main supply failure.

Conversely, in minimum fail-safe mode, the relay de-energizes when the level falls below the desired level or in the event of mains supply failure. It is important to note that the contacts depicted on the Logic Card Panel are for Fail Safe Low Mode and will vary when the Fail Safe Mode is altered.

Maintenance

Maintenance for the Vibration Switch is minimal, as it does not require regular upkeep. However, in cases where the material has a tendency to build up, the tines should be cleaned as needed. It is also important to ensure that the cable glands and housing lid are properly sealed to prevent moisture from entering.

Location

Report abuse

Report abuse

Featured