Vibrating Rod Point Switch (VRS) – Pune Techtrol

Description

Vibrating Rod Point Switches are commonly used for level detection of granules and powders in small silos and bins. These switches are based on piezo-driven vibration technology. Unlike vibrating fork switches, they have a round-shaped vibrating rod that prevents typical bridging problems resulting in false alarms.

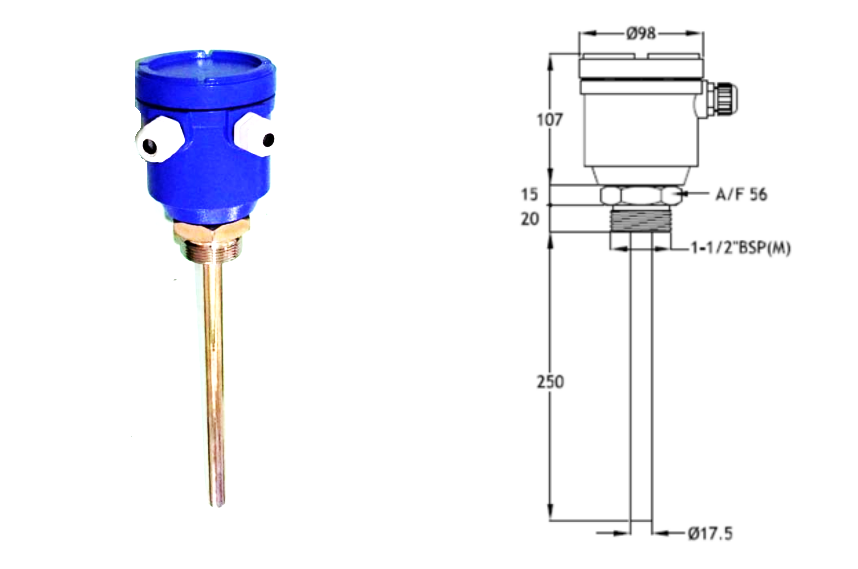

Vibrating Rod Point Switch

The vibrating rod point switches use a sensing rod with integral electronics that are housed in an enclosure at its top. When power is supplied, the sensing rod is set into mechanical vibrations at its resonance frequency, driven by piezo crystal.

As the rod gets covered with material, the vibrations are damped, which is sensed by the electronics. This change in vibration is used to trigger change over contacts, which can be used for alarm indication/control or connected to PLC/DCS.

The vibrating rod point switches are easy to install and are commonly used in the food and beverage, chemical, and pharmaceutical industries.

Generally, We use a protective shield to protect the vibrating rod from the direct impact of material falling on the rod at the inlet or during loading, which may cause damage to the rod.

Applications of Vibrating Rod Point Switch

The Vibrating Rod Point Switch finds its applications in a wide range of materials including milk, chocolate, coffee powder, flour, spices, coffee beans, tea, salt, sugar, grains, peanuts, sweets, candy, animal and pet food, cellulose, polystyrene, glass fine powder, cement, dry soot, soda ash, coal ash, foundry sand, gravel, granular plastics, plastic pellets, wood shavings, and chalk.

Vibrating Rod Point Switch Specifications

Sensing probe

- Mounting: Top/Side

- Vibrating Rod MOC: SS304

- Pr. Connection MOC: SS304 (Screwed), CS /SS304 (Flange)

- Process Connection: 1-1/2” BSP (M) Screwed or 1-1/2” ASME 150# Flange

- Insertion Length: 250 mm to 3000 mm

- Resonance Freq: 300 Hz

- Particle/ Grain Size: upto 20 mm :

- Min. Bulk Density: >0.5 g/cm3

- Max Temperature: 150 ⁰C

- Test Pressure: -1 to 10 bar

Electronics (Integral)

- Enclosure: Cast Al. IP66 protection

- Cable Gland: PG13.5 x 2 nos, Polyamide

- Supply: 65 to 265 V AC or 24 VDC ±10%

- Output: Potential free relay contacts 5A, 230VAC, 2 x SPDT

- Power Consumption: 1.8VA (AC), 1.5W (DC)

- LED Indication: Green (Normal) & Red (Alarm)

- Fail-Safe Selection: High (FSH), Low (FSL) field selectable

- Switching Delay: 2 to 20-second adjustable probe free to probe covered (Optional)

- Amb. Temperature: 0 to 60 ⁰C

Attachments

Location

Report abuse

Report abuse

Featured