Conductivity Type Level Switch (CNS) – Pune Techtrol

Description

The conductivity type level switch is a cost-effective and reliable level control device, specifically created to identify conductive liquids that do not emit fumes.

Conductivity Type Level Switch

The Conductivity type level switch (CNS) is a device used for detecting the level of conductive liquids and the interface level between conductive and non-conductive liquids.

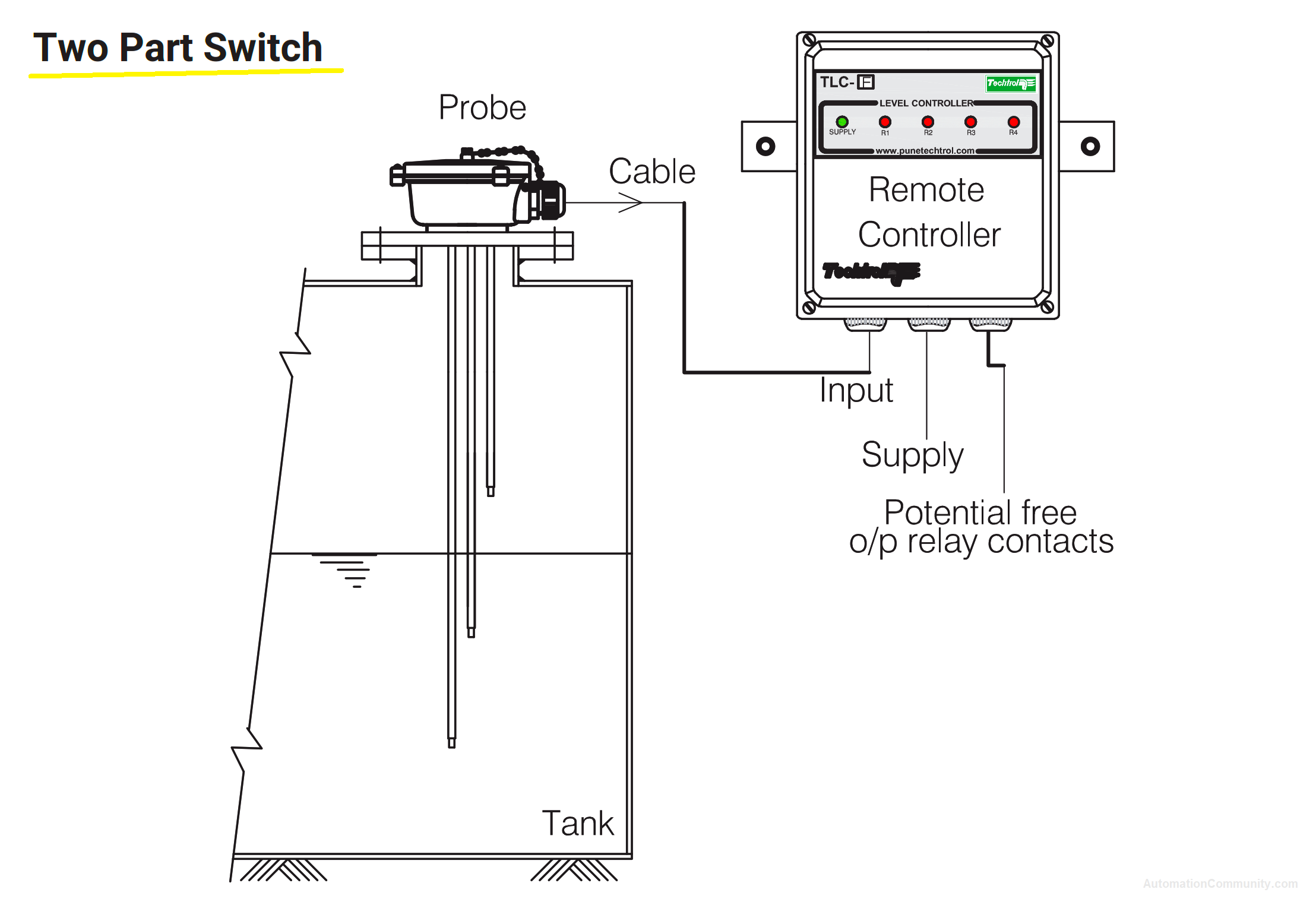

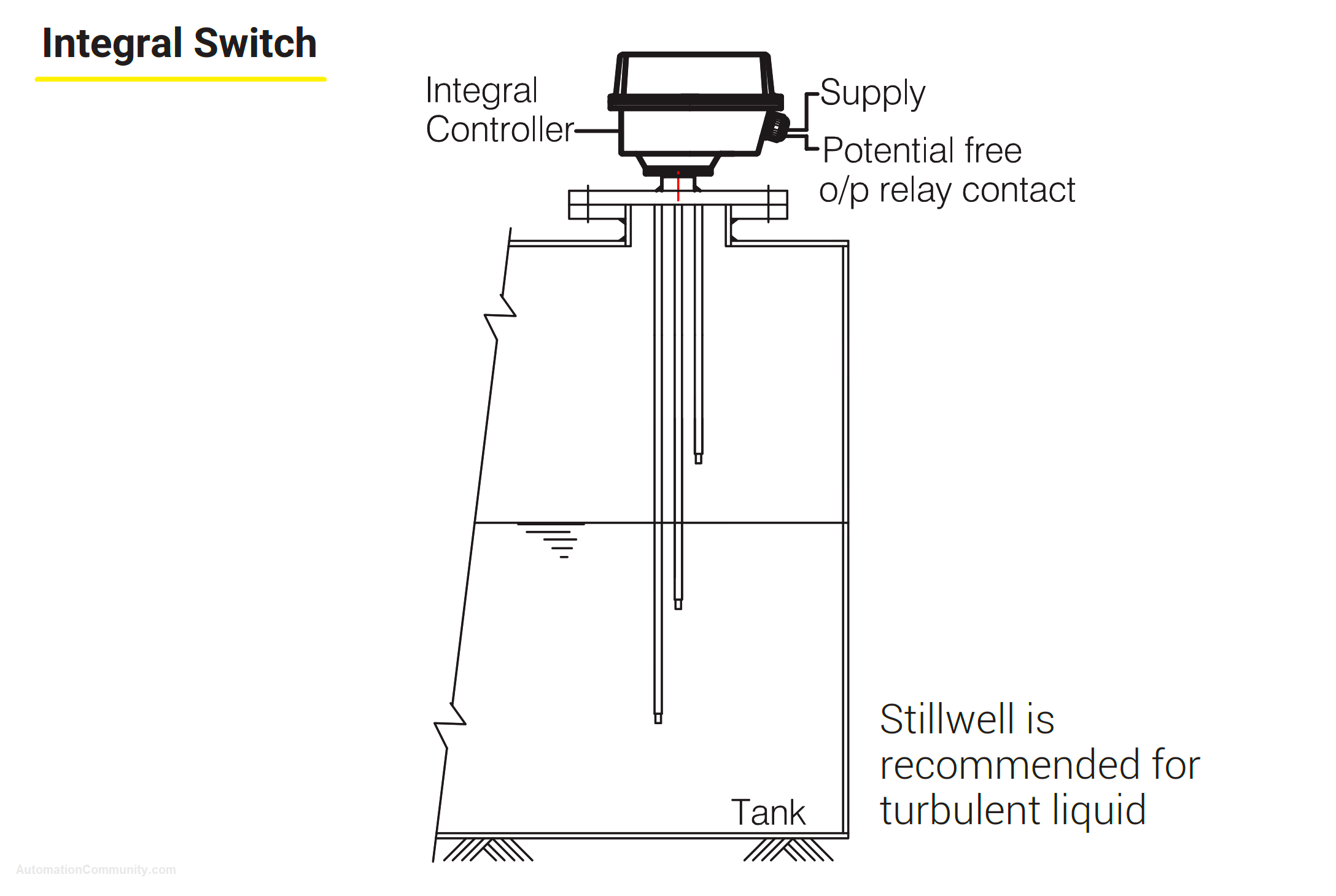

The conductivity level switch consists of a probe and a controller, which activate potential free contacts at preset levels to operate auxiliary devices such as pumps, solenoid valves, and DCS.

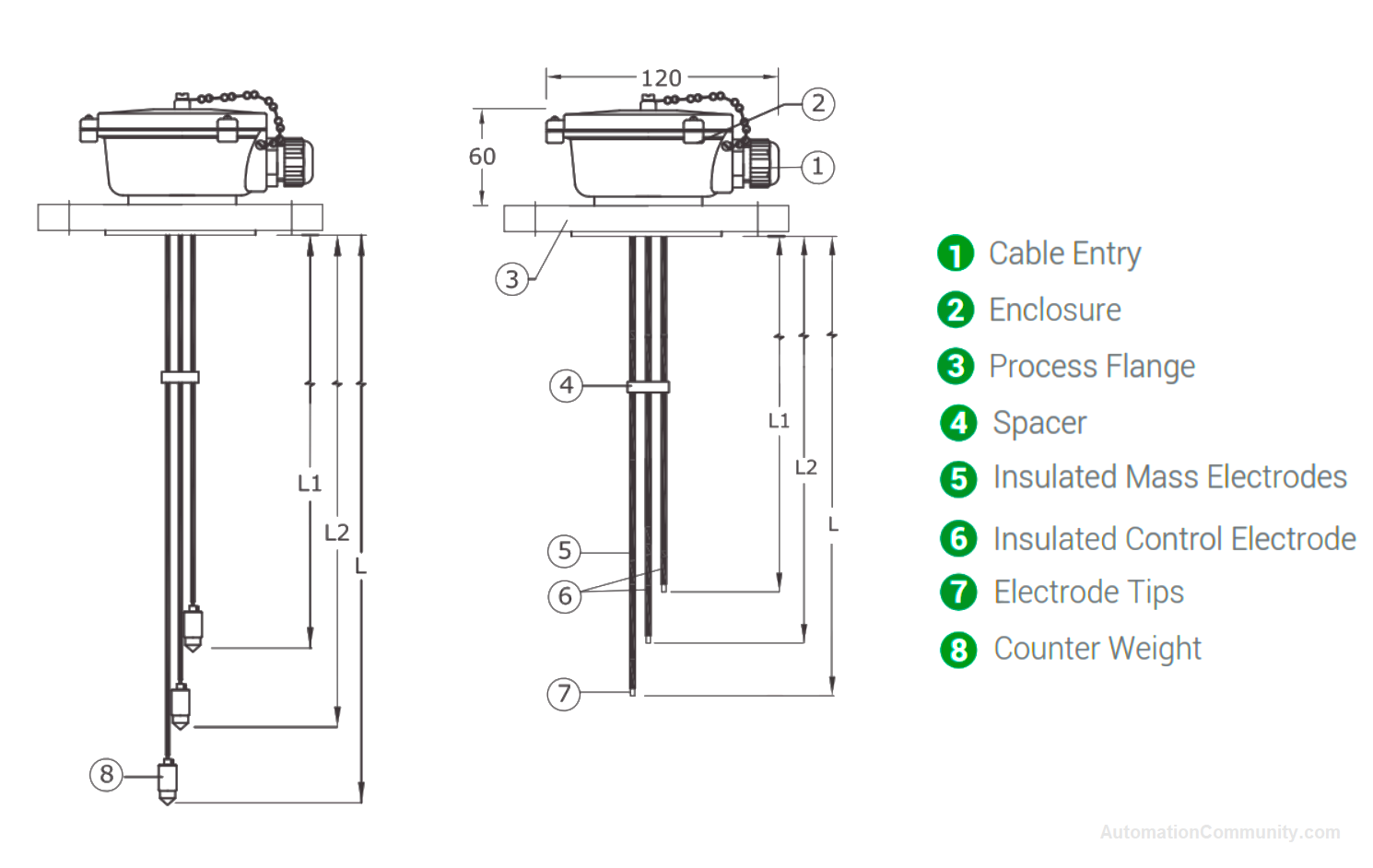

The probe has a mass electrode and one or more control electrodes that correspond to the number of preset levels and location of sensing points, respectively. The rising liquid level comes in contact with the tip of the sensing electrode, completing the circuit, and actuating the relay for control action.

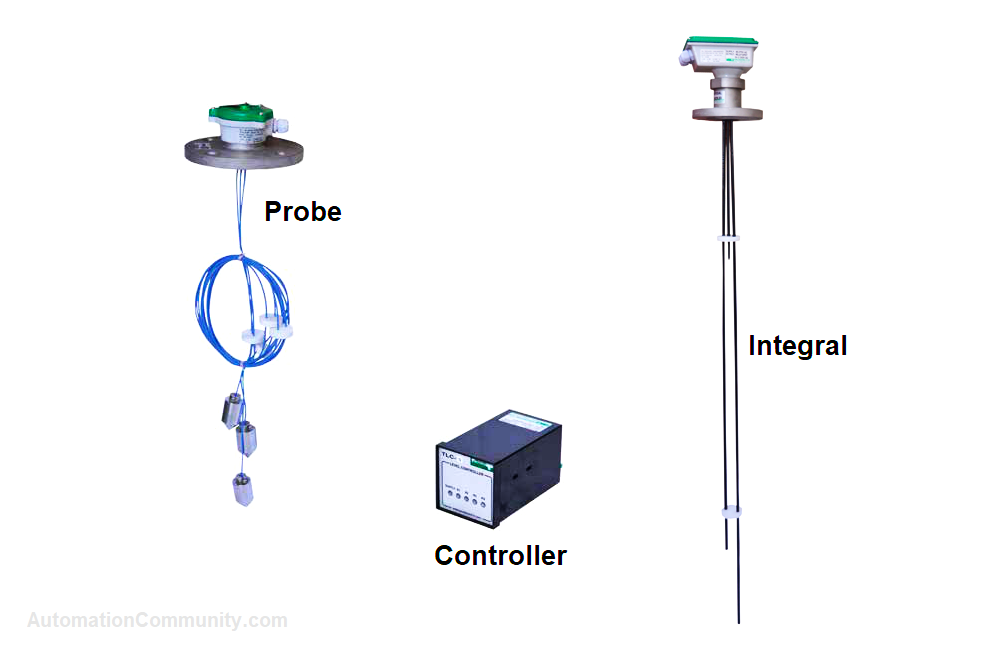

The CNS is available in two constructions: one with a separate probe and controller and the other with an integral probe and controller. The control unit is available in three types of enclosures: a two-part system, an integral system, and a CNS-TLC-N system.

This level switch applications in industries such as process industry, sumps, reservoirs, cooling towers, water treatment, ETP, building automation systems, and filtration systems.

Conductivity Probes

When mounting the CNS probe, it’s important to ensure that the process connection matches the tank’s counter connection and to use a suitable gasket to prevent leakage.

For outdoor mounting, the cable termination should be routed downwards before the cable gland to prevent water seepage into the enclosure.

To adjust the electrodes to the required preset level, the mass electrode should match the tank depth and other control electrodes should be cut to the appropriate length without damaging the insulation.

Solid electrodes require 10/15 mm of insulation to be removed from the tip to ensure conductivity, while suspended electrodes require 5/10 mm of insulation to be removed and the counterweight should be fixed to the wire rope with the given screw.

Specifications of Conductivity Type Level Switch

Probe

- Probe Enclosure: Cast Al. IP66 x PG 11 Cable Gland (Nylon) or Conduit Conn. Cast Al. Exd Gr. IIB T6 IP66 x 1/2″ NPT DC Cable Gland (Brass)

- Process Connection: Flanged or screwed

- Process Conn. MOC: CS or SS304 or SS316

- Electrode Types: Rigid, 100 to 2000 mm; Flexible, 500 to 10000 mm

- Electrode MOC: PVC/ PTFE insulated SS304 or SS316, PVC/ PTFE insulated SS316 with Hastelloy Tip, PVC /PTFE insulated SS316 with Titanium Tip

- Mass Electrode: One

- Control Electrode: One to Four

- Max. Temperature: 700 C (PVC insulation), 1000 C (PTFE insulation)

- Max.Test Pressure: 5 kg/cm2

- Liquid Conductivity: ≥25 us

- Contacts: 5A, 250VAC x SPDT

- Enclosure: Cast Al, IP66 or Ex-P IIB

Maintenance of Conductivity Type Level Switch

For maintenance of the conductivity type level switch, it is important to clean the electrode tip to remove any scaling deposits. If the liquid is viscous or contains suspended material, regular cleaning is necessary.

The terminal screws should be checked and tightened if needed. The probe should be visually examined for any damage like sleeving breakage or probe rod bending. In the case of a wall-mounted controller, the inside should be cleaned to remove any dust or foreign particles.

After maintenance, it is important to ensure weather-proofed by closing the enclosure with its cover and gasket. If the switch is located in a hazardous area, the enclosure cover should not be opened before disconnecting the switch from the supply to prevent ignition or explosion.

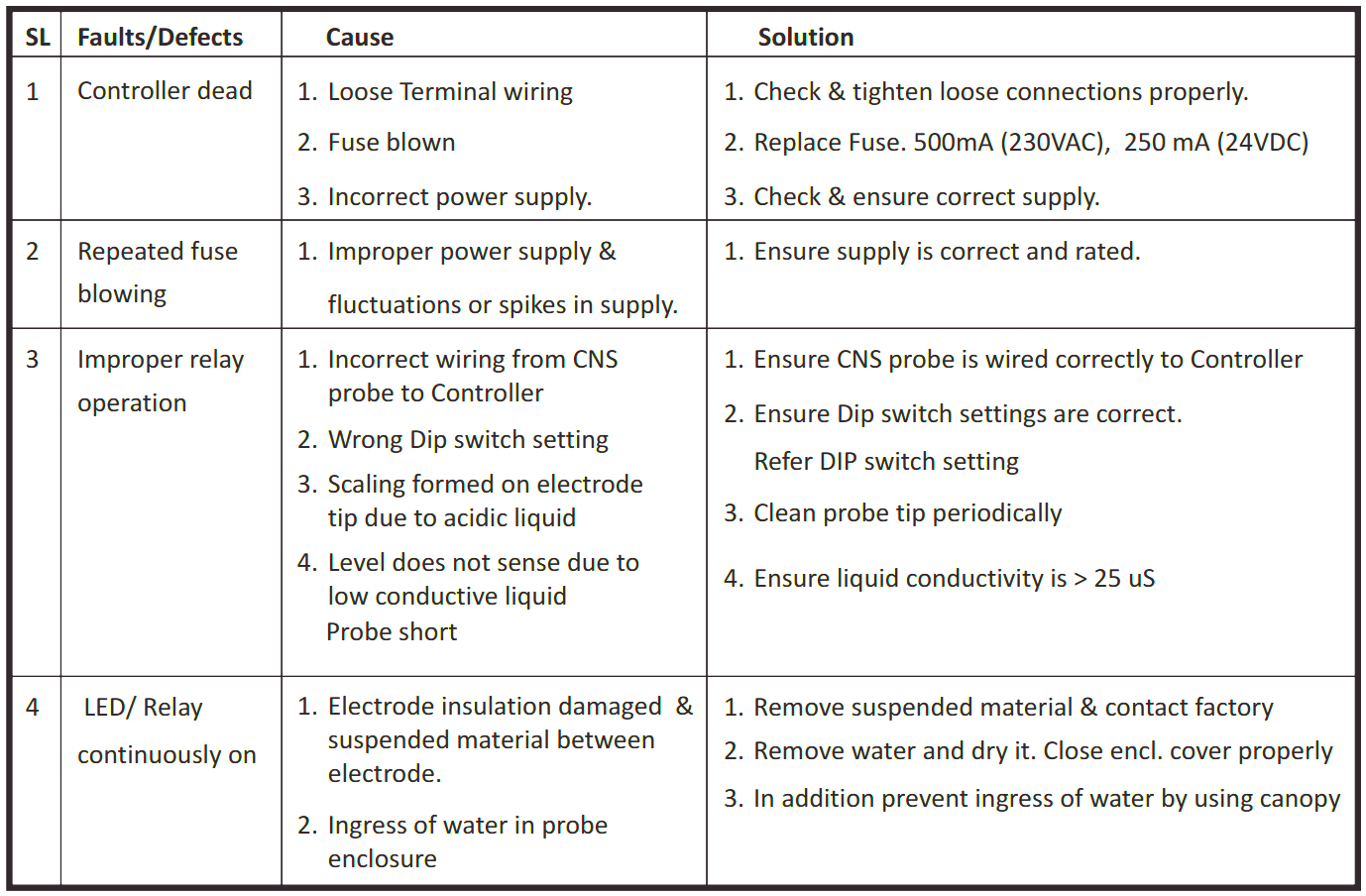

Troubleshooting Conductivity Type Level Switch

Some of the problems and solutions of the Conductivity Type Level Switches are mentioned below.

Location

Report abuse

Report abuse

Featured