Conductivity Contamination Level Sensor – Pune Techtrol

Description

The Conductivity Contamination Level Sensor is a solid-state level switch that is specifically designed to detect the presence or absence of electrically conductive liquids in diesel/fuel oil or any hydrocarbon.

Conductivity Contamination Level Sensor

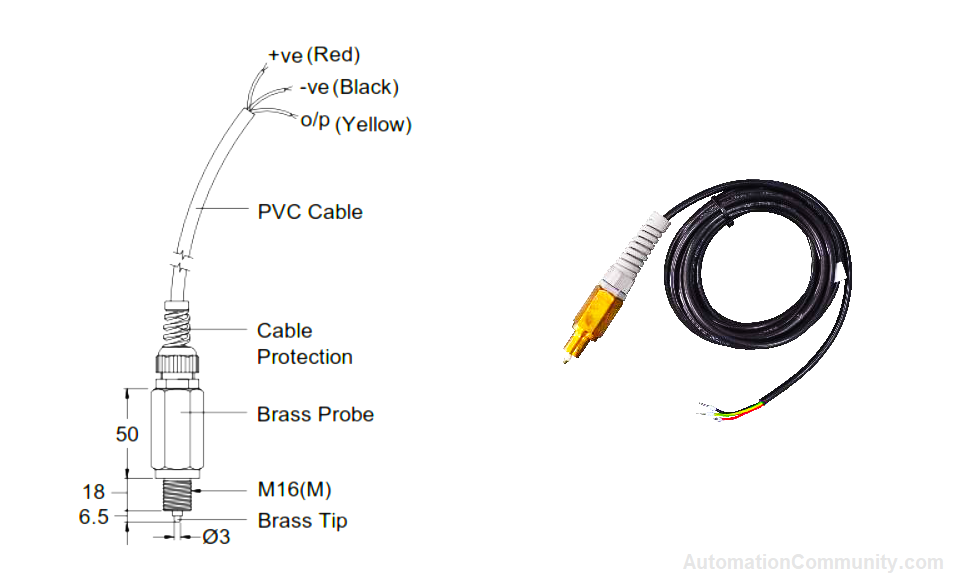

The Conductivity Contamination Level Sensor comprises a brass probe that houses integral electronics, which generate an alternating voltage to its brass tip.

When the sensor detects the presence of water or any other electrically conductive liquid, it completes the circuit, leading to a change in the condition of the transistor output.

The probe can be side-mounted using a screwed mounting, and the other end is connected to a PVC cable, which allows it to be submerged in a tank to detect contamination. The brass tip is insulated with PTFE to prevent electrical bridging with the probe.

The sensor can provide a signal output in the form of PNP or NPN to activate a relay, indication light, or interface with a PLC or SCADA system.

Specifications of Conductivity Contamination Level Sensor

- Probe: Brass

- Mounting: M16 (M) x1.5 pitch

- Probe Tip: Brass x Ø3

- Tip Insulation: PTFE

- Protection: IP-68 (submersible)

- Resistance: 40K ohms (max)

- Signal Voltage: 6VAC, 20mA

- Extended Cable: 3 Core, PVC x 1mtr long 0.75 mm2

- Supply: 12 VDC

- Output: PNP or NPN

- Temp. Range: -10 to +80°C

- Max Test Pressure: 3Kg/cm2

Applications

The Conductivity Contamination Level Sensor finds its applications in various industries for detecting the presence of electrically conductive liquids. It is widely used for fuel contamination and leak detection purposes, especially in diesel and fuel oil tanks.

It can also be used for monitoring coolant levels in radiators and water levels in oil separators. It can be utilized in various other applications where the presence of electrically conductive liquids needs to be detected.

Installation of Conductivity Contamination Level Sensor

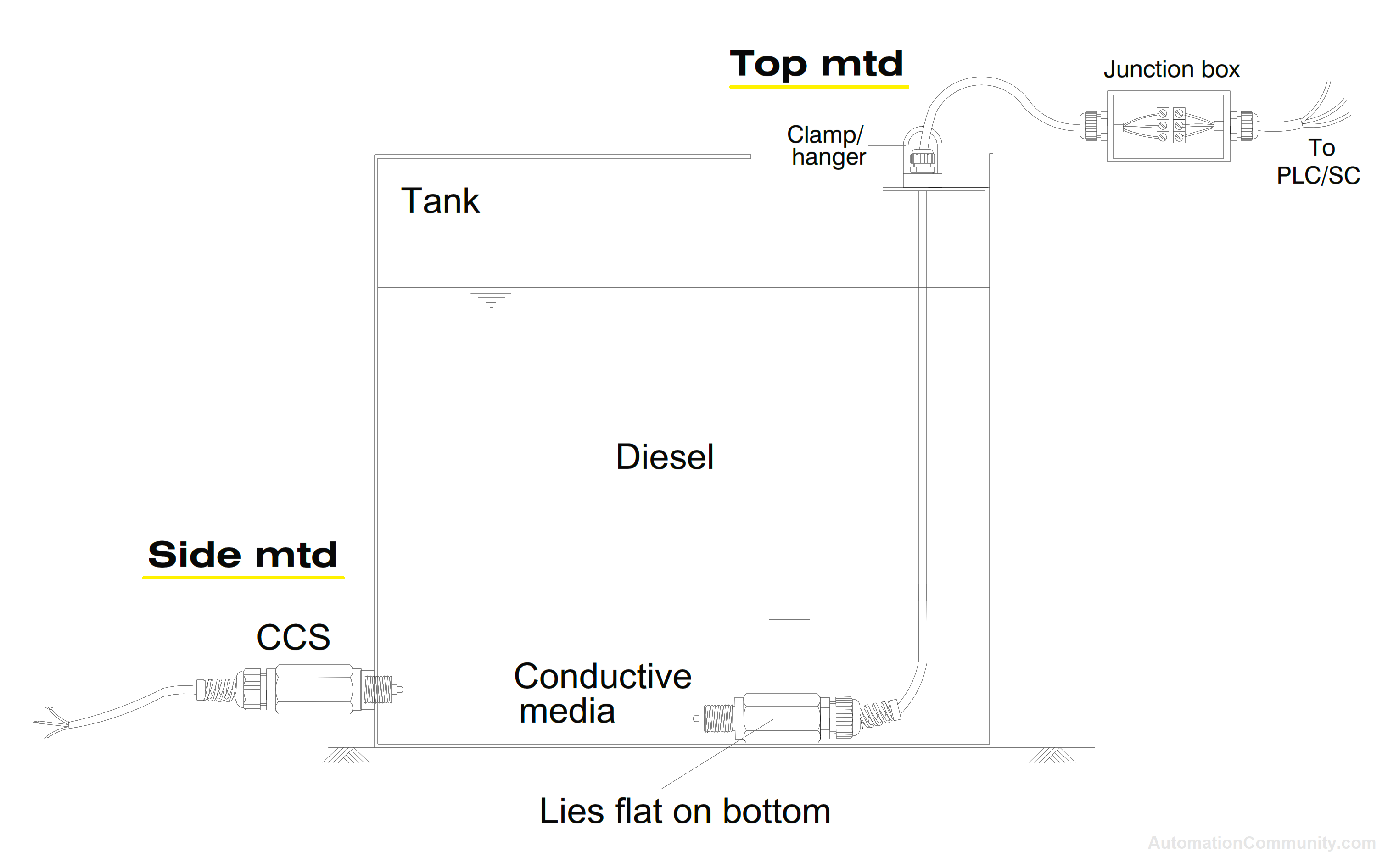

For top installation, the level sensor probe should be lowered into the tank and submerged in the liquid until its probe body is lying flat at the bottom. The probe should then be suspended through a cable gland that is fitted on a clamp, and the wire should be terminated at an appropriate junction box for further connections to PLC/SCADA.

For side installation, the mounting position of the probe should be located where the conductive liquid is likely to be present. The probe is provided with a screwed connection and should be fitted on the side of the tank.

Precautions

When installing the sensor, it is important to take certain precautions. These include:

- Avoid sharp bends in the wire during installation.

- Ensure that the probe is mounted in a way that its tip, along with the partial probe, comes in contact with the conductive liquid.

- Do check the wiring before turning on the power supply.

- Do not exceed the temperature and pressure limits to prevent damage to the sensor.

Conductivity Level Sensor Maintenance

To perform maintenance on the sensor, follow these steps:

- Switch off the power supply to the sensor before starting maintenance work.

- Check all connections for looseness and tighten them if necessary.

- Use a soft cloth or brush to periodically clean the probe tip. Avoid using a hard wire brush, which can damage the probe.

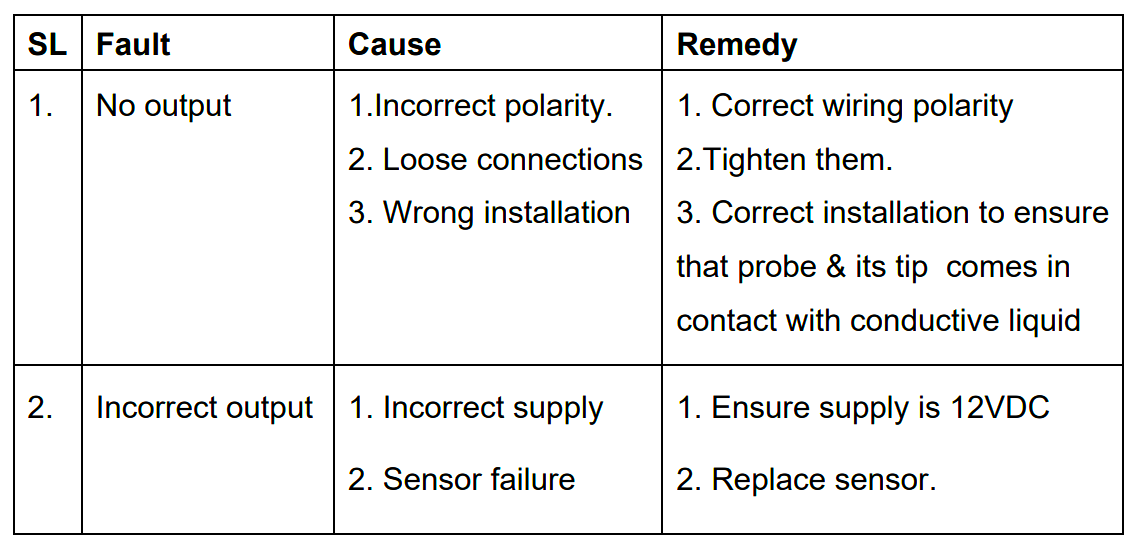

Troubleshooting Conductivity Level Sensor

Some of the problems and solutions of Conductivity Contamination Level Sensors are mentioned below.

Location

Report abuse

Report abuse

Featured