Cable Suspended Tilt Switch (FTS) – Pune Techtrol

Description

Cable Suspended Tilt Switch is designed to detect high levels in silos, chutes, and the presence of material on conveyor belts. This switch comprises a 3-core cable in varying lengths, with an integral cone at one end.

The cone houses a microswitch internally that triggers when the cone tilts in any direction from its normal vertical position.

Cable Suspended Tilt Switch

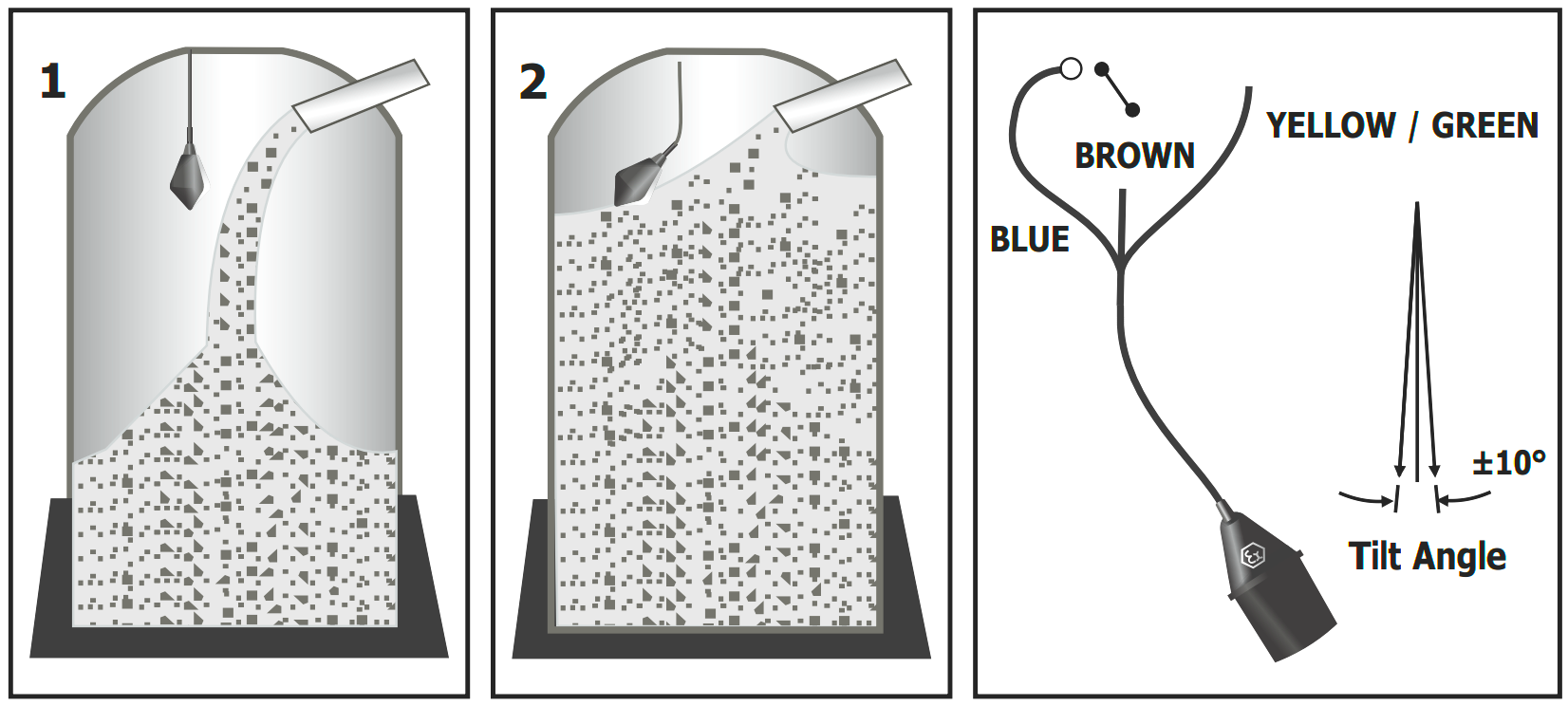

During the filling operation of a silo, the tilt level detector switch remains suspended in a vertical position.

Once the material in the silo reaches a high level, it causes the switch to tilt by more than 10 degrees. This tilting action activates the microswitch inside the cone of the switch, which in turn triggers an auxiliary device to stop the filling operation of the silo.

Types of Tilt Float Switches

Tilt-type float switches are designed to detect liquid levels in tanks of different sizes and shapes. They are suspended from a 3-core cable in plumb and are available in various lengths.

Tilt switches come in three different shapes, including Disc/Bioconical shapes for large tanks, Tubular & Mini-tubular shapes for small tanks, and Cone shapes to detect high levels in Silos.

Applications of Cable Suspended Tilt Switch

Some of the applications of tilt switches are mentioned below.

Silios High-Level Detection

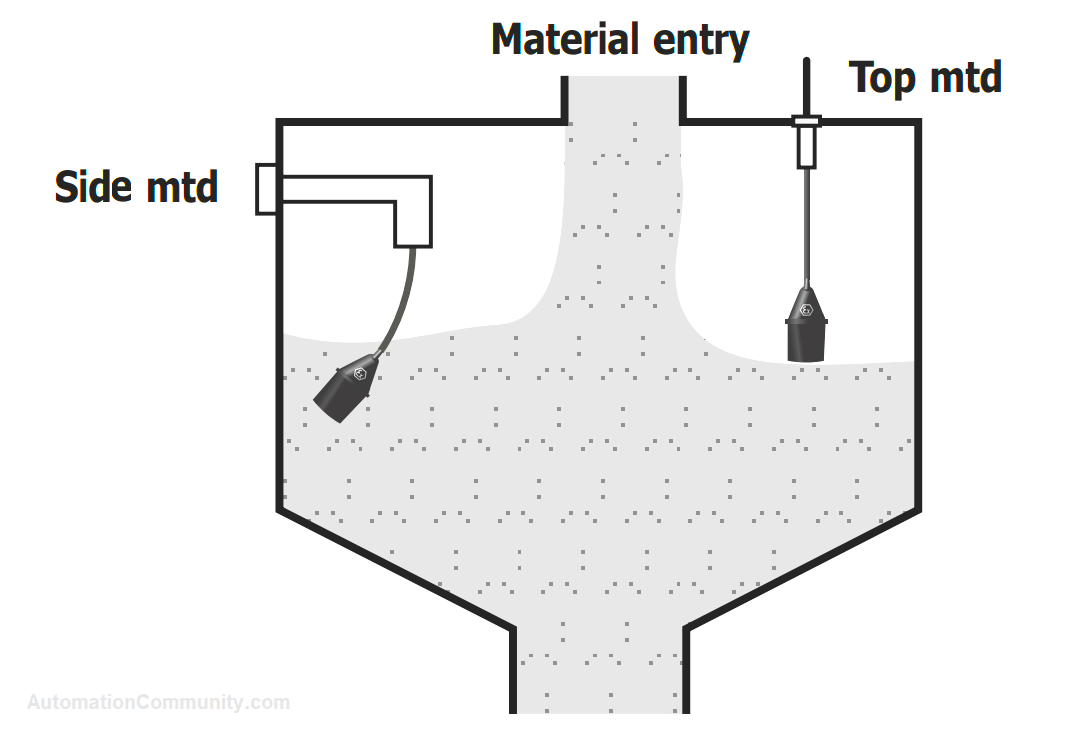

The tilt float switch can be mounted either on the side or the top of the silo for detecting a high level of free-flowing materials entering the silo. The switch is suspended in a vertical position, away from the material entry point.

Once the material reaches the desired high-level detection point, it tilts the cone of the switch, activating the microswitch and stopping the filling operation.

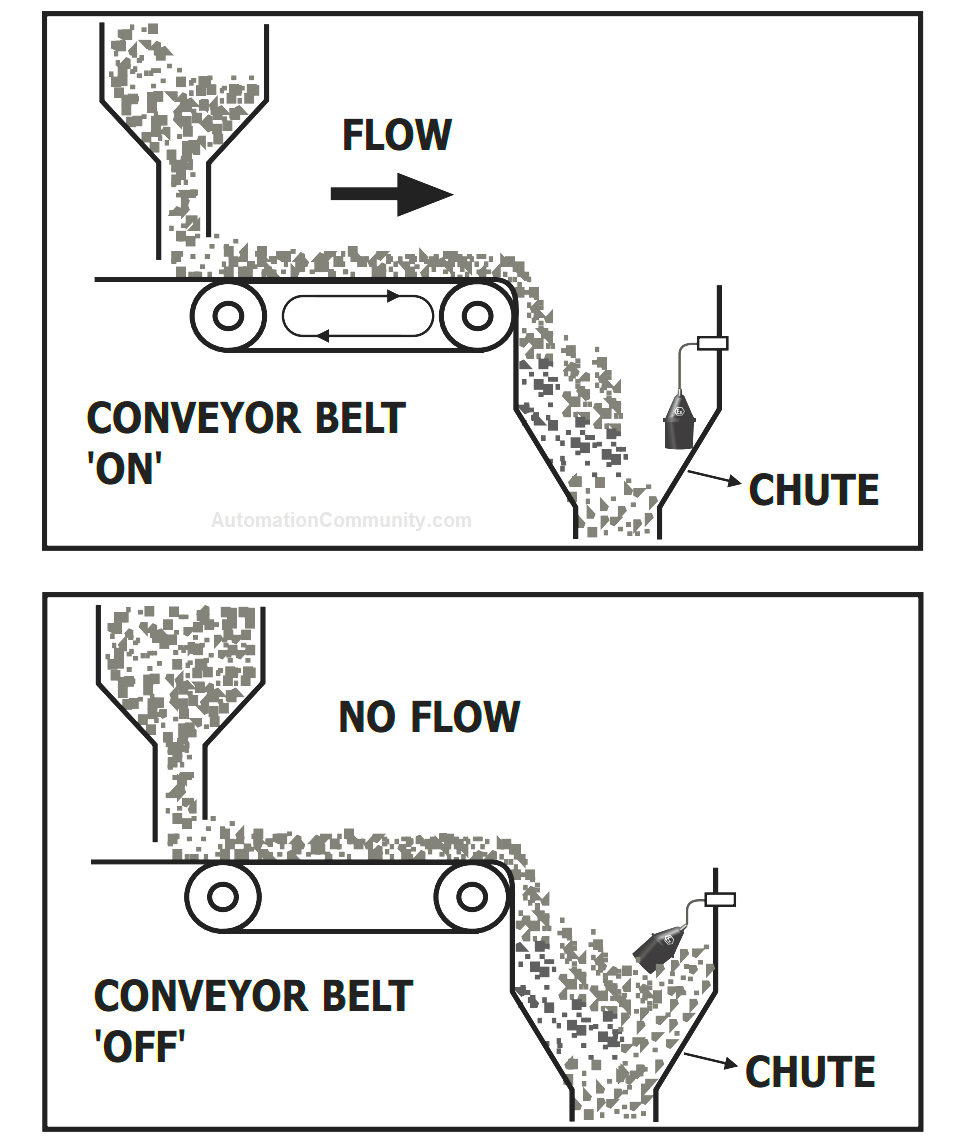

Chute Jam Detection

This type of switch is called a Jamming Switch or a Chute Jam Detector. It is designed to prevent material from accumulating and causing a blockage in the chute, which can lead to equipment damage and downtime.

The switch is typically installed at the top of the chute and suspended vertically with a plumb line. When material builds up and jams the chute, the switch tilts and triggers an alarm or shutdown signal to stop the conveyor belt and prevent further material from entering the chute.

Installation of Cable Suspended Tilt Switches

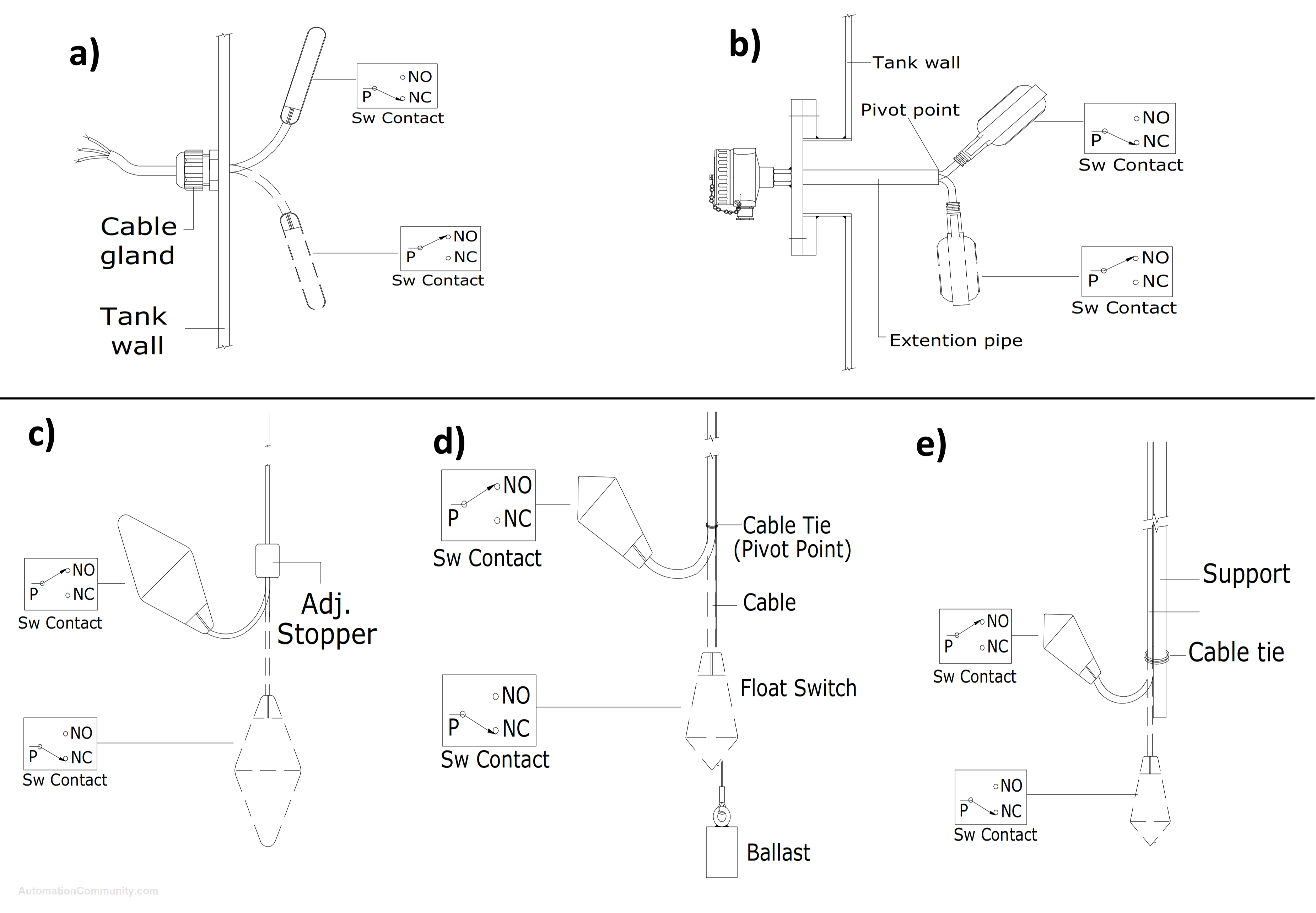

the Installation Cable Suspended Tilt Switch can be installed from both the top and the side of the tank. For side-mounted systems, cable glands or extension pipes can be used for installation, while top-mounted systems can be configured and installed using adjustable stoppers, suspended ballasts, or support pipes.

These different installation options provide flexibility in selecting the most appropriate method for a particular application.

- Figure a – cable gland

- Figure b – extension pipe

- Figure c – adjustable stopper

- Figure d – suspended ballast

- Figure e – support pipe

Maintenance of Cable Suspended Tilt Switch

The Maintenance of the Cable Suspended Tilt Switch is:

- Switch off the power supply during maintenance.

- The switch is completely sealed and requires no maintenance. Replace it, If it malfunctions.

- The temperature and pressure do not exceed the limits.

- Visually examine the float for punctures and the cable for any damage.

- Tighten the bolts and electrical connections if they are loose.

- After maintenance, ensure that the enclosure is weatherproof (IP66) by closing it with its gasket, and make sure that the cable is tightly secured in the cable gland with no gaps.

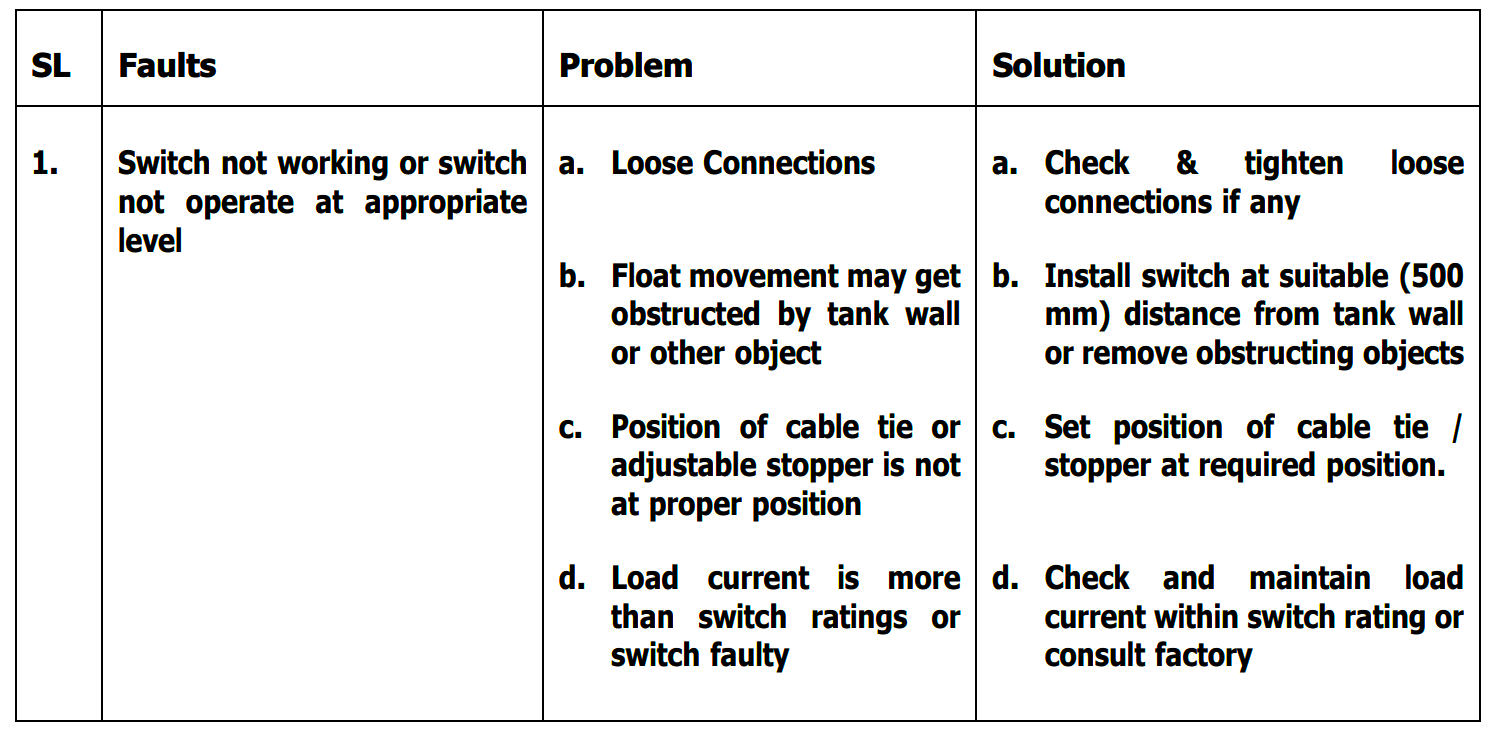

Troubleshooting of Cable Suspended Tilt Switch

Some of the problems and solutions of cable-suspended tilt switches are mentioned below.

Location

Report abuse

Report abuse

Featured