Chamber Float Magnetic Level Switch (CFS) – Pune Techtrol

Description

The Magnetic Level Switch with Chamber Float is a dynamic and versatile solution for accurately monitoring liquid levels in one or two preset levels.

It uses either a single switch mechanism for one level or a double switch mechanism for two levels, making it adaptable for a wide range of applications where precise level control is critical.

Chamber Float Magnetic Level Switch

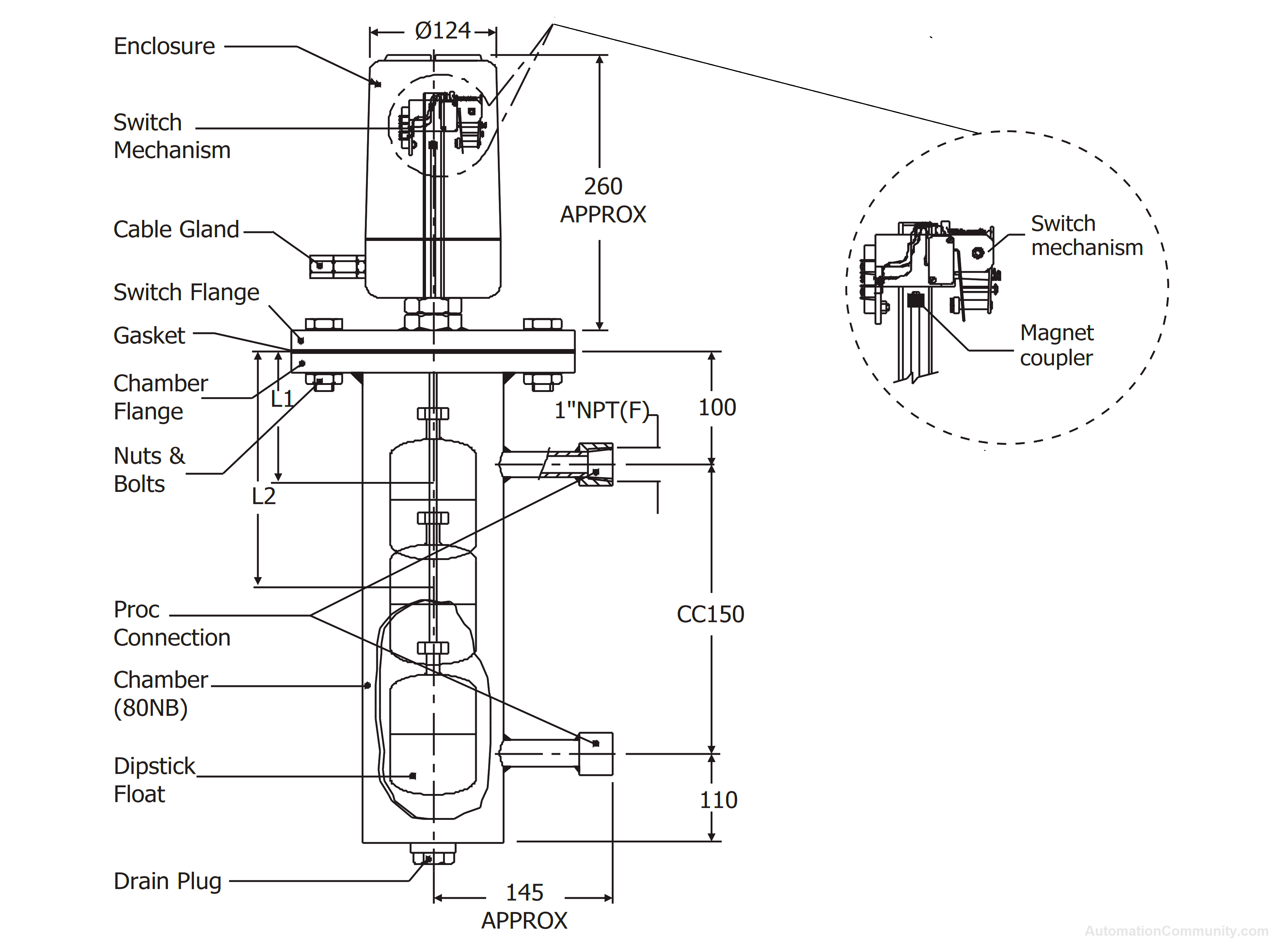

The Chamber Float Magnetic Level Switch operates by using a dipstick float with a magnet coupler located at its top end.

The float rises and falls with changes in the liquid level, and the unique magnetic system within the sealed pipe causes the switch contacts mounted inside the enclosure to make or break, providing a “snap action” bistable latch-on switching mechanism.

Specifications

- Range: 200 – 400mm CCD

- Wtd Parts: CS, SS304, SS316, PP

- Max. Temp: 300ºC

- Max. Pressure: 10 Kg/cm2

- Liquid Density: ≥0.8 g/cm3

- Contacts: 5A,250VAC x SPDT

- Enclosure: Cast Al x IP66 or Ex-P IIB or IIC

Installation of Chamber Float Magnetic Level Switch

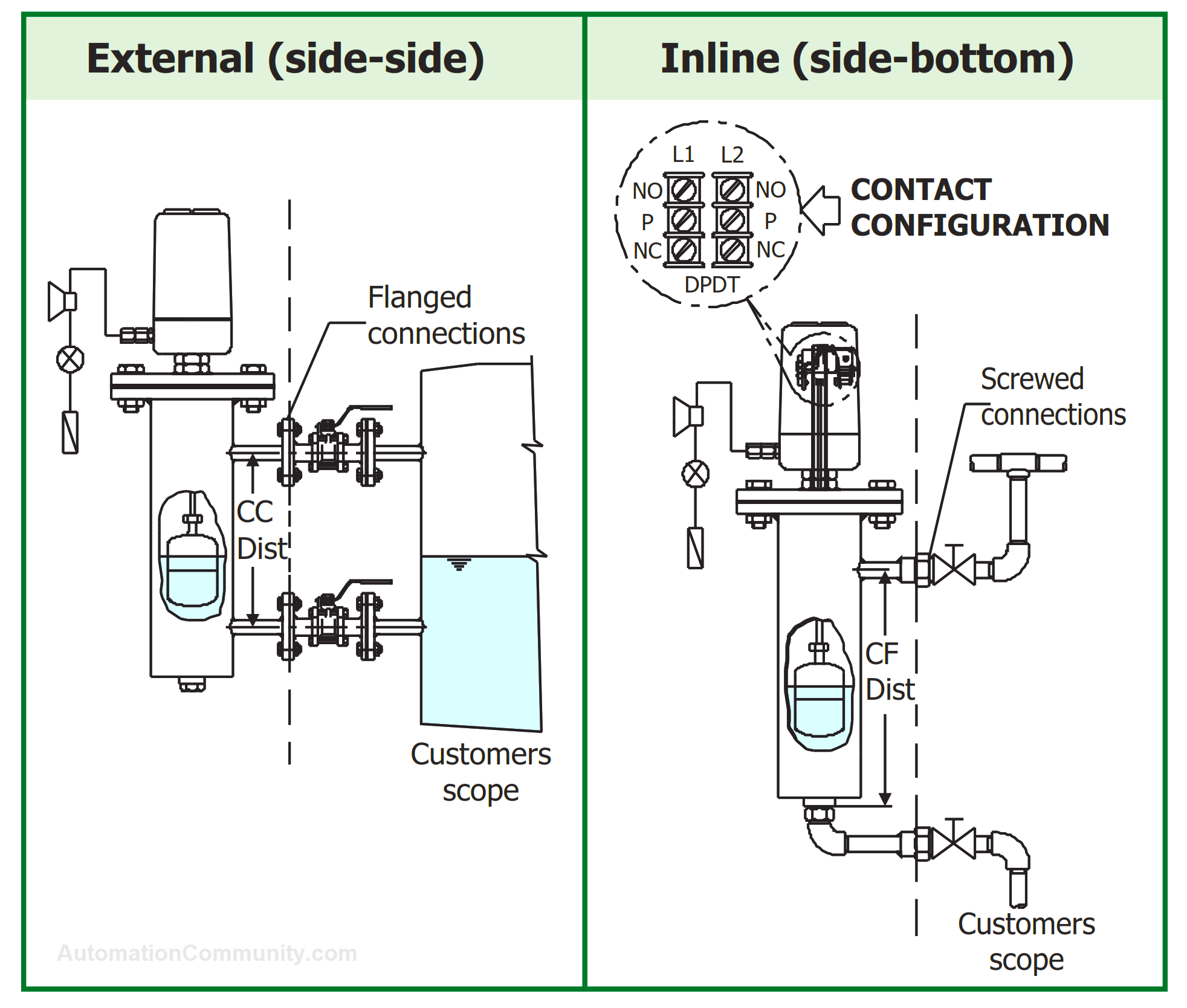

During the installation of the level gauge, it is important to choose a location on the tank with minimal vibrations and ensure that the process connections and center-to-center distance of the gauge match those on the tank.

Flange connections require matching flanges with identical orientations, while screwed/SMS union connections require matching threads and types. Counter connections provided on the tank should be vertical and in a plumb line.

Gaskets should be used between flanges and appropriate thread sealant between threads before bolting to prevent leakage. Pump suction or outlet for the process should not be connected to the drain point of the gauge.

Isolating valves should be provided on the tank for safety and to facilitate the removal of the gauge for repair or maintenance.

Chamber Float Level Switch Maintenance

The maintenance instructions:

- Regularly clean the float and chamber if the liquid contains dirt or suspended particles.

- Clean the switches frequently if the liquid has high viscosity or floating material.

- Check that terminal connection are secure.

- Inspect the switch contacts for pitting or oxidation caused by sparking.

- Always ensure that the enclosure cover is properly secured.

- Before opening the device, disconnect it from the power supply to prevent ignition in hazardous atmospheres

Applications of Chamber Float Level Switch

For optimal performance, it is important to use the Chamber Float Magnetic Level Switch under specific operating conditions such as specific gravity, temperature, and pressure.

The switch is designed for use with fluids having a specific gravity between 0.8 and 1.5, as indicated in the test report that accompanies the instrument. Maintaining these conditions will ensure the accuracy and reliability of the switch.

Typical Services

The Chamber Float Magnetic Level Switch finds application in a variety of services such as level detection, alarms, and pump control for liquid and slurry storage sumps and tanks.

It is also suitable for drum level switching in Non-IBR boilers.

Troubleshooting of Chamber Float Magnetic Level Switch

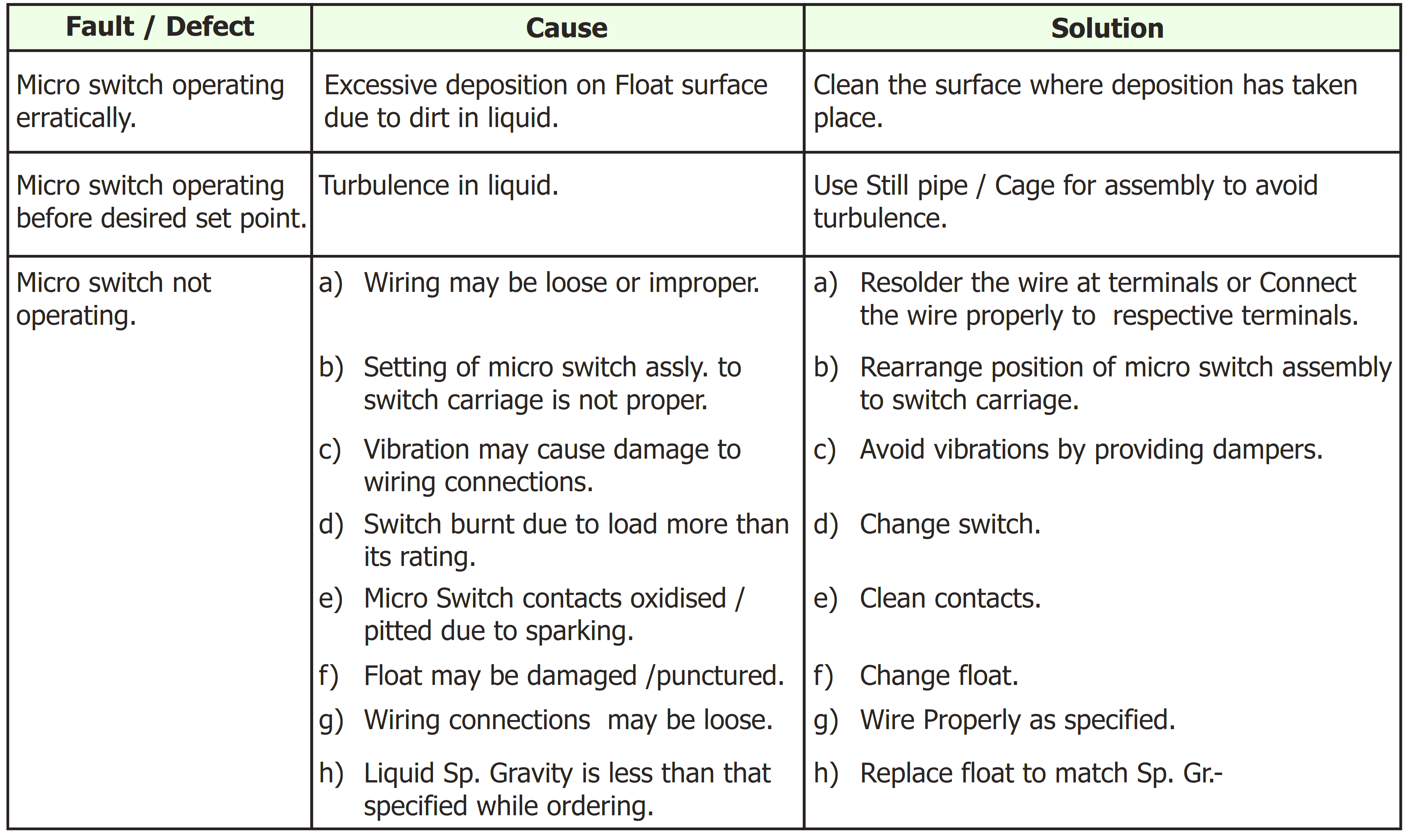

Some of the problems and solutions of Chamber Float Magnetic Level Switch is mentioned below.

Location

Report abuse

Report abuse

Featured