Profinet Questions and Answers – Industrial Communication

Expand your knowledge of industrial communication protocols with our unique collection of Profinet questions and answers. Test your knowledge, troubleshoot issues, and optimize your Profinet networks with this unparalleled resource. Enhance your understanding of Profinet and stay ahead in the world of industrial communication.

Profinet Questions

What is Profinet?

Profinet is an industry technical standard for data communication over Industrial Ethernet, designed for collecting and transmitting control information in real-time.

What is the main use of Profinet?

Profinet is used for industrial automation systems where high-speed, deterministic communication is required.

Who developed Profinet?

Profinet was developed by Profibus & Profinet International (PI), a consortium of companies in the automation industry.

What are the key features of Profinet?

Some key features include real-time communication, flexibility, scalability, and the ability to transmit IT data and control information on the same network.

What is Profibus and how does it relate to Profinet?

Profibus is a Fieldbus standard for industrial control systems. Profinet, on the other hand, is designed for real-time data communication over Industrial Ethernet. Both were developed by the same organization.

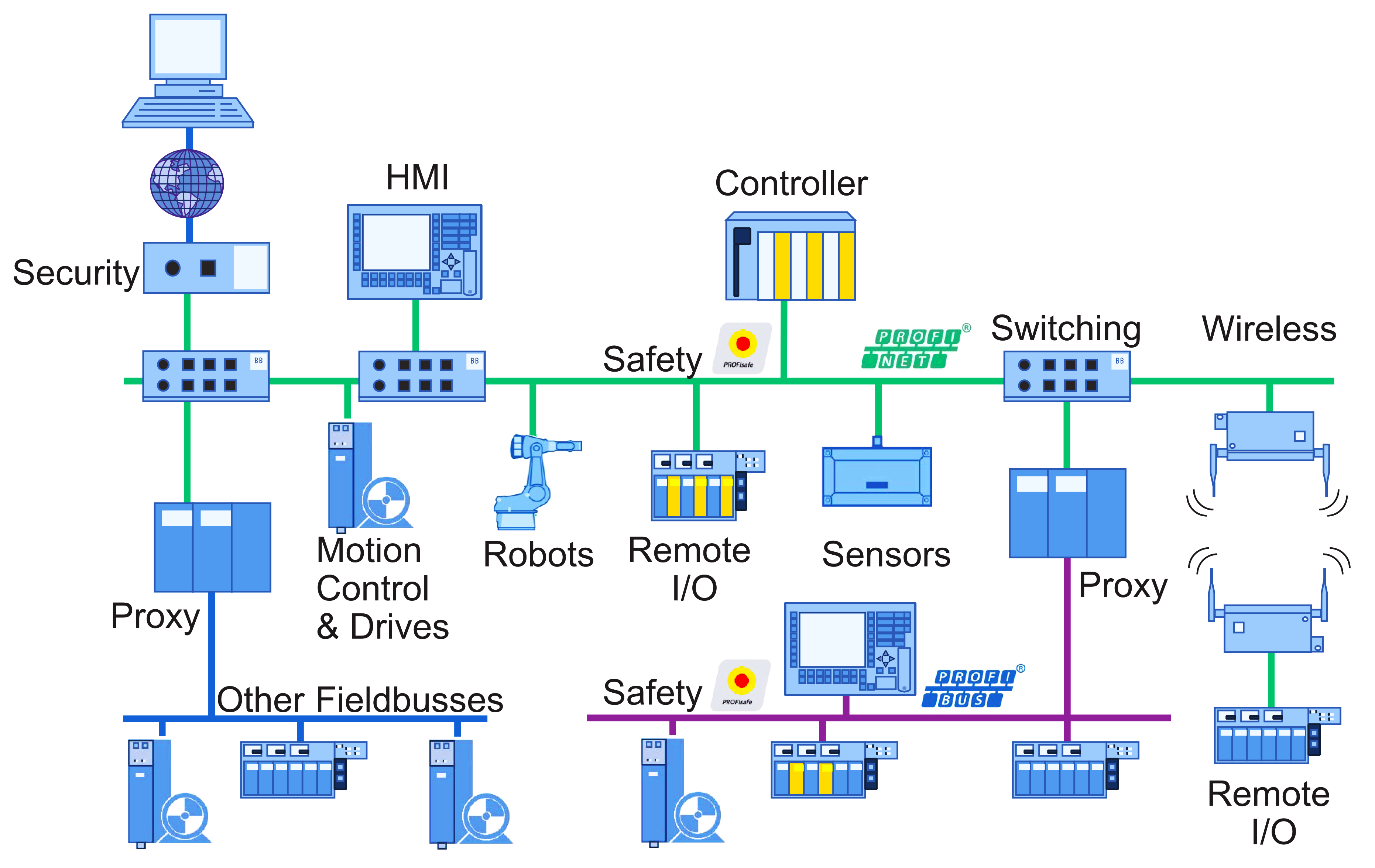

What types of devices can be connected to a Profinet network?

Devices such as programmable logic controllers (PLC), human-machine interfaces (HMI), sensors, drives, and actuators can be connected to a Profinet network.

How does Profinet handle real-time communication?

Profinet has a mechanism called “IRT” (Isochronous Real-Time) for applications that need extremely precise synchronization and low jitter.

Can Profinet work with standard Ethernet equipment?

Yes, Profinet can use standard Ethernet equipment like switches, cabling, and connectors, which can help reduce costs.

How does Profinet ensure network reliability?

Profinet uses a number of mechanisms to ensure network reliability, including redundancy options, ring topology support, and alarms for rapid fault detection and diagnostics.

What kind of data can Profinet transmit?

Profinet can transmit both process data (control data) and IT data (like HTTP, TCP/IP) over the same network.

What does IRT stand for in Profinet?

IRT stands for Isochronous Real-Time. It’s a feature of Profinet designed to ensure precise, deterministic communication for time-critical applications.

What is the maximum number of nodes that can be connected in a Profinet network?

Profinet can theoretically support up to 65,535 nodes per network, which provides extensive scalability for industrial systems.

What are GSD files in Profinet?

GSD (General Station Description) files are used in Profinet to describe the properties and functionalities of devices, such as input/output size, module options, and parameter data.

What does Profinet CBA stand for?

Profinet CBA stands for Component-Based Automation. It’s a part of Profinet designed for distributed, modular systems where components can be interconnected flexibly.

How does Profinet handle network diagnostics?

Profinet supports extensive diagnostic capabilities, allowing for swift identification and localization of faults. Alarms can be issued to signal network or device issues, aiding quick resolution.

What is the data rate of Profinet?

Profinet operates over standard Ethernet and can support data rates of 100 Mbps or 1 Gbps, depending on the network infrastructure.

How does Profinet compare to Ethernet/IP?

Both Profinet and Ethernet/IP are Ethernet-based protocols used for industrial automation. While they have many similarities, Profinet tends to be more prevalent in Europe, while Ethernet/IP is more commonly used in the Americas.

What types of topologies does Profinet support?

Profinet supports various network topologies, including line, star, ring, and tree topologies, allowing flexibility in system design.

What does Profinet RT stand for?

Profinet RT stands for Real-Time. It’s designed to handle real-time communication requirements in automation systems, though it’s not as precise as Profinet IRT.

What is MRP in Profinet?

MRP stands for Media Redundancy Protocol. It’s standard for industrial Ethernet that allows rings of network switches to overcome any single network failure, enhancing network reliability.

How does Profinet support functional safety?

Profinet supports functional safety via PROFIsafe, a profile that enables safe communication between control systems and safety devices, like emergency stops and light curtains.

Can Profinet be used wirelessly?

Yes, Profinet can be used over wireless LAN, ensuring that moving parts or remote components of a system can still communicate effectively.

How does Profinet support device integration and configuration?

Profinet uses a standard XML schema for device descriptions, making it easier for manufacturers to integrate and users to configure devices.

What is the role of a Profinet controller?

A Profinet controller is responsible for controlling the operations of devices connected to the Profinet network. It could be a PLC, PAC, or industrial PC.

What is a Profinet device name?

A Profinet device name is a unique identifier for a device on the Profinet network. It allows the controller to identify and address the device.

What is Profinet DCP?

DCP stands for Discovery and Configuration Protocol. It’s used for setting and getting device properties like the device name and IP address, and for identifying devices in the network.

How is time synchronization handled in Profinet?

Profinet uses the Precision Time Protocol (IEEE 1588) for time synchronization across devices. This ensures accurate timing for the sequence of events and time-stamping.

How does Profinet handle security?

Profinet has multiple layers of security, including physical security, network access control, and defense against network threats. Profinet also recommends additional measures like firewalls and VPNs.

What types of cables are used for Profinet?

Profinet typically uses standard Ethernet cables. However, for high industrial durability, specially designed Profinet cables can be used that resist oil, heat, and other harsh conditions.

How does Profinet support energy management?

Profinet supports energy management through PROFIenergy, a profile that allows coordinated pausing of production equipment during non-productive times to save energy.

What are the benefits of using Profinet?

Benefits of Profinet include real-time communication, high data transparency, extensive diagnostic capabilities, flexible topologies, and easy integration with existing Ethernet networks.

How does Profinet handle motion control?

Profinet supports motion control through the PROFIdrive profile, which standardizes drive technology, allowing for both standard and safety-related drive control.

What is a Profinet IO device?

A Profinet IO device is an end device, such as a sensor or actuator, that is controlled by a Profinet IO controller.

How do you configure a Profinet network?

Profinet networks can be configured with engineering tools that allow the user to set up the network architecture, assign device names and IP addresses, and configure device parameters.

What’s the importance of the Profinet certification?

Profinet certification ensures that a device complies with Profinet standards and will function correctly within a Profinet network.

What are Profinet proxies?

Proxies are devices that act as an interface between Profinet and other Fieldbus systems, like PROFIBUS or AS-i, allowing integration of different network technologies.

Can Profinet work with OPC UA?

Yes, Profinet can work together with OPC UA. While Profinet is ideal for real-time control data, OPC UA can handle higher-level communication for data exchange with IT systems.

What is PROFINET PN/IO?

PN/IO is a part of the Profinet standard that defines how I/O data is exchanged in real-time between Profinet controllers and devices.

How does Profinet support plug-and-play functionality?

Profinet supports plug-and-play through automatic address assignment, device replacement without the need for engineering tools, and easy device identification and commissioning.

What is Fast StartUp in Profinet?

Fast StartUp (FSU) is a feature in Profinet that enables devices to startup and be ready for operation within 500 milliseconds, useful in modular machines and systems with frequent tool changes.

What is the purpose of Profinet’s ‘Shared Device’ feature?

The ‘Shared Device’ feature allows multiple controllers to access the same I/O device. This is useful in redundancy systems or when data from one device needs to be processed by multiple controllers.

How does Profinet integrate safety technology?

Profinet integrates safety technology via PROFIsafe, which allows for standard and safety-related communication over the same network without additional hardware.

What is the ‘I-Device’ feature in Profinet?

The ‘I-Device’ (Intelligent Device) feature allows a device to be both a controller and a device simultaneously. This supports more complex automation structures and enables hierarchical control structures.

How does Profinet deal with network load?

Profinet uses mechanisms like Real-Time (RT) and Isochronous Real-Time (IRT) to handle network load. RT is used for cyclic data exchange, while IRT allows precise scheduling of data exchange to manage network load.

How does Profinet support the commissioning of devices?

Profinet simplifies commissioning by supporting plug-and-play functionality, automatic device naming and addressing, and detailed diagnostics for troubleshooting.

What is ‘Topology Detection’ in Profinet?

‘Topology Detection’ in Profinet allows for the automatic recognition of the network topology. This provides a clear overview of the network and aids in diagnostics and troubleshooting.

Can Profinet networks be remotely monitored?

Yes, Profinet networks can be remotely monitored. Diagnostic data can be accessed remotely, and alerts can be set up to notify the appropriate personnel of any issues.

What are ‘Profiles’ in Profinet?

‘Profiles’ in Profinet standardize certain functionalities for different classes of devices. Profiles like PROFIdrive, PROFIenergy, or PROFIsafe define common functions for drives, energy management, and safety technology respectively.

How does Profinet enable the concept of the ‘Digital Twin’?

Profinet supports the creation of a ‘Digital Twin’ by providing real-time data from devices. This data can be used to create a virtual representation of the system for simulation, diagnostics, and optimization.

How does Profinet support Industry 4.0?

Profinet supports Industry 4.0 through its capabilities for real-time communication, integration of IT systems via TCP/IP and OPC UA, and support for digitalization through features like the Digital Twin.

How is a Profinet system designed and implemented?

Designing a Profinet system involves choosing the appropriate devices and controllers, planning the network topology, and configuring the devices. This is usually done with the help of specialized engineering tools.

How does Profinet fit into the TSN (Time Sensitive Networking) landscape?

Profinet can work with TSN, an upcoming set of standards for deterministic networking. The combination of Profinet and TSN is expected to provide even greater precision in communication and control tasks.

How is error handling managed in Profinet?

Profinet offers extensive diagnostic capabilities. Errors can be detected at the device or network level, and alarm mechanisms can notify operators immediately when errors occur.

How are software updates handled in Profinet?

Software updates for Profinet devices can be handled remotely using firmware update mechanisms. This allows for efficient maintenance and upgrade of Profinet systems.

What makes Profinet suitable for process automation?

Profinet is suitable for process automation due to its real-time communication capabilities, integration of process instruments, extensive diagnostics, and support for functional safety and redundancy.

How does Profinet support machine vision applications?

Profinet can integrate with machine vision systems to allow for real-time communication of image data and control information, enabling high-speed image processing in automation systems.

What is ‘IRT Class 3’ in Profinet?

‘IRT Class 3’ is the highest performance level of Profinet IRT and allows for the most precise synchronization and communication cycle times as low as 31.25 µs.

What is the significance of ‘Asset Management’ in Profinet?

‘Asset Management’ involves the monitoring and management of devices in a Profinet network. This includes tasks like configuration management, device diagnostics, and preventative maintenance.

How can a Profinet device be replaced in case of failure?

Profinet supports easy device replacement. When a device fails, a new device can be installed and will automatically be recognized and configured by the controller, often without the need for any manual intervention.

What is the expected future development of Profinet?

Future development of Profinet includes greater integration with TSN for improved real-time capabilities, further support for OPC UA for IT integration, and continued development of profiles for specialized device functionalities.

What is ‘PROFIsafe Black Channel Principle’ in Profinet?

The ‘Black Channel Principle’ refers to PROFIsafe’s ability to use any type of transmission channel, whether wired or wireless, without needing to be concerned with the channel’s safety-related characteristics.

What is the role of a ‘Conformance Test’ in Profinet?

A ‘Conformance Test’ ensures that a Profinet device has been developed in compliance with Profinet standards and can interact correctly with other Profinet devices.

What types of automation systems typically use Profinet?

Profinet is commonly used in various types of automation systems, including manufacturing automation, process automation, and drive technology. It’s also used in emerging fields like robotics and machine vision.

What is the difference between Profinet ‘Device’ and ‘Interface’?

A ‘Device’ in Profinet is typically an end device, like a sensor or actuator. An ‘Interface’ refers to the Profinet communication interface of a device or controller.

How does Profinet support the concept of ‘Predictive Maintenance’?

Profinet supports ‘Predictive Maintenance’ by providing extensive diagnostic data from devices. This data can be analyzed to detect patterns and predict potential device failures before they occur.

How is ‘Redundancy’ handled in Profinet?

Profinet supports ‘Redundancy’ through features like Shared Device and Media Redundancy Protocol (MRP), which allow for the setup of redundant controllers and network paths to increase system availability.

What is ‘Seamless Redundancy’ in Profinet?

‘Seamless Redundancy’ refers to the ability of Profinet to switch over to a redundant system component without any interruption of communication, ensuring continuous system operation.

What is the role of a ‘Network Supervisor’ in Profinet?

A ‘Network Supervisor’ in Profinet is a tool used to monitor the health and performance of a Profinet network. It can provide detailed diagnostic information and help to optimize network performance.

How does Profinet handle ‘Versioning’?

‘Versioning’ in Profinet involves managing different versions of device descriptions and firmware, ensuring compatibility, and enabling easy upgrades.

What is the role of an ‘Application Profile’ in Profinet?

An ‘Application Profile’ in Profinet defines device functionalities for a specific application domain, like drives or energy management. This allows for easy device interchangeability and standardization across a specific industry.

How does Profinet interact with Cloud-based platforms?

Profinet can interact with Cloud-based platforms via gateways or edge devices. This allows for the collection of data from Profinet networks for further analysis and storage in the Cloud.

How does Profinet integrate with Industrial IoT?

Profinet’s real-time communication capabilities, support for TCP/IP, and ability to work with OPC UA make it an ideal networking technology for the Industrial Internet of Things (IIoT).

What does ‘Distributed Clocks’ mean in Profinet?

‘Distributed Clocks’ in Profinet is a feature that allows for precise synchronization of devices on a Profinet network. This is crucial for coordinated motion control and other time-sensitive applications.

How is data encapsulated in Profinet?

Data in Profinet is encapsulated using standard Ethernet frames. Real-time data is exchanged using special Profinet RT or IRT frames.

Can Profinet be used in hazardous areas?

Yes, Profinet devices can be designed to be used in hazardous areas. They must be specially designed and certified to ensure they don’t pose a risk of ignition.

How are Profinet networks diagnosed?

Profinet networks are diagnosed using tools that can monitor network traffic, check device statuses, and analyze error counters. Profinet also offers extensive built-in diagnostics.

How is device firmware updated in Profinet?

Device firmware in Profinet can be updated remotely from a controller or engineering tool. This allows for easy maintenance and upgrades of Profinet devices.

How can Profinet networks be optimized?

Profinet networks can be optimized by properly planning the network architecture, managing the network load, and using diagnostic tools to identify and fix any issues.

How can Profinet be used in mobile equipment?

Profinet can be used in mobile equipment by using wireless communication. This allows for real-time communication with moving components.

What types of devices can be integrated into a Profinet network?

Various types of devices can be integrated into a Profinet network, including sensors, actuators, drives, cameras, PLCs, and even devices from other networks via proxies.

What is the primary purpose of Profinet?

Profinet’s primary purpose is to provide a robust and flexible communication network for industrial automation, integrating real-time industrial control with standard Ethernet communication.

Can you describe the basic architecture of a Profinet system?

A basic Profinet system consists of Profinet controllers (like PLC) and Profinet devices (like sensors, actuators, and drives). These are interconnected via a standard Ethernet network infrastructure.

How does Profinet handle real-time data?

Profinet handles real-time data using Real-Time (RT) and Isochronous Real-Time (IRT) communication. RT is used for standard real-time data exchange, while IRT provides more precise synchronization for motion control applications.

What is the role of GSD (General Station Description) files in Profinet?

GSD files describe the properties and capabilities of a Profinet device. They are used by the engineering tool to configure the device and set up communication with the controller.

How does Profinet handle device naming and addressing?

Profinet devices are identified by a device name, which is unique in the network. They are also assigned an IP address for standard Ethernet communication.

How does Profinet ensure data security?

Profinet provides security measures like data encryption and access control. It can also be integrated with additional industrial security measures, like firewalls and intrusion detection systems.

What is the difference between a Profinet ‘Class A’ and ‘Class B’ device?

‘Class A’ devices in Profinet support RT communication and basic diagnostics, while ‘Class B’ devices additionally support IRT communication, Media Redundancy Protocol (MRP), and advanced diagnostics.

What types of data can be exchanged in a Profinet network?

Profinet allows for the exchange of various types of data, including cyclic I/O data, acyclic parameter data, and alarms.

How does Profinet enable scalability in industrial networks?

Profinet is highly scalable, allowing for small networks with few devices to large systems with thousands of devices. It supports different network topologies and allows for network extensions and upgrades.

How does Profinet support different network topologies?

Profinet supports various network topologies like line, tree, star, and ring. This flexibility allows for the design of networks that best fit the requirements of the industrial application.

What is the role of ‘Fast Startup’ in Profinet?

‘Fast Startup’ is a Profinet feature that allows devices to start communication within a few hundred milliseconds after power-up or a network interruption. This is particularly useful in applications with high availability requirements.

How does Profinet handle network disruptions?

Profinet handles network disruptions using redundancy features like Media Redundancy Protocol (MRP) for network paths and ‘Shared Device’ for controllers. It also supports ‘Fast Startup’ for quick recovery after a network interruption.

Can you describe the ‘Peer-to-Peer Communication’ in Profinet?

‘Peer-to-Peer Communication’ in Profinet allows for direct communication between Profinet controllers or between devices, bypassing the usual master-slave communication pattern. This can be useful for distributed control applications.

How does Profinet ensure the interoperability of devices?

Profinet ensures the interoperability of devices by defining clear standards and profiles. All Profinet devices must pass a conformance test to ensure that they comply with the Profinet standards.

What are the benefits of using Profinet in industrial automation?

Benefits of using Profinet in industrial automation include real-time communication, integration with IT systems, high scalability, flexibility in network design, extensive diagnostics, and support for functional safety and energy efficiency.

How is time synchronization achieved in Profinet?

Time synchronization in Profinet is achieved using the Precision Time Protocol (PTP) and the Distributed Clocks feature. This allows for precise synchronization of actions across multiple devices.

How does Profinet support energy efficiency?

Profinet supports energy efficiency via the PROFIenergy profile, which allows for coordinated power management of devices during production breaks, reducing energy consumption.

What is the function of the ‘Application Relation (AR)’ in Profinet?

The ‘Application Relation (AR)’ in Profinet is the connection between a Profinet controller and a device, including the configuration of the device and the communication parameters.

What types of applications typically use the Profinet IRT communication class?

Profinet IRT is typically used in applications that require precise synchronization and low jitter, such as coordinated motion control.

How does Profinet support the integration of legacy fieldbuses?

Profinet supports the integration of legacy fieldbuses using ‘proxy’ devices, which act as gateways between the Profinet network and the legacy fieldbus devices.

Read Next: