OPC Questions and Answers – Open Platform Communication

Learn OPC questions and answers to understand Open Platform Communication basics, architecture, protocols, and troubleshooting. This resource provides valuable insights and solutions to enhance your OPC knowledge.

Open Platform Communication

What is OPC?

OPC stands for OLE for Process Control. It is a set of standards and specifications for industrial telecommunication. OPC defines the interface between clients and servers, as well as servers and servers.

OPC, originally ‘OLE (Object Linking and Embedding) for Process Control’, was established to facilitate interoperability in process control and automation systems. The name is now known as ‘OPC’, reflecting its application beyond just OLE.

What are the main components of OPC?

The main components of OPC are OPC Server, OPC Client, and OPC Configurator.

OPC Server manages the hardware interface, OPC Client communicates with OPC Server, and OPC Configurator is used to configure the OPC Server.

Can you explain what OPC is?

OPC stands for OLE for Process Control. It’s a set of standards and specifications that promotes interoperability in industrial automation and process control.

What are the primary components of an OPC system?

The primary components of an OPC system are the OPC Server, OPC Client, and OPC Configurator.

Can you describe the different types of OPC?

The main types of OPC are OPC DA (Data Access), OPC UA (Unified Architecture), OPC HDA (Historical Data Access), and OPC A&E (Alarms and Events).

What is the purpose of an OPC Server?

The OPC Server facilitates communication between the hardware and the OPC Client. It manages the hardware interface and translates data into a format that the OPC Client can understand.

How does an OPC Client function?

An OPC Client communicates with the OPC Server. It requests data from or sends commands to the server, which then communicates with the hardware.

Can you explain OPC DA?

OPC DA stands for Data Access. It allows real-time data communication between OPC Clients and Servers.

What is OPC HDA?

OPC HDA stands for Historical Data Access. It allows access to historical data from process automation systems.

Can you describe OPC A&E?

OPC A&E stands for Alarms and Events. It’s used for event-driven data communication, providing information about process alarms and changes.

What is OPC UA?

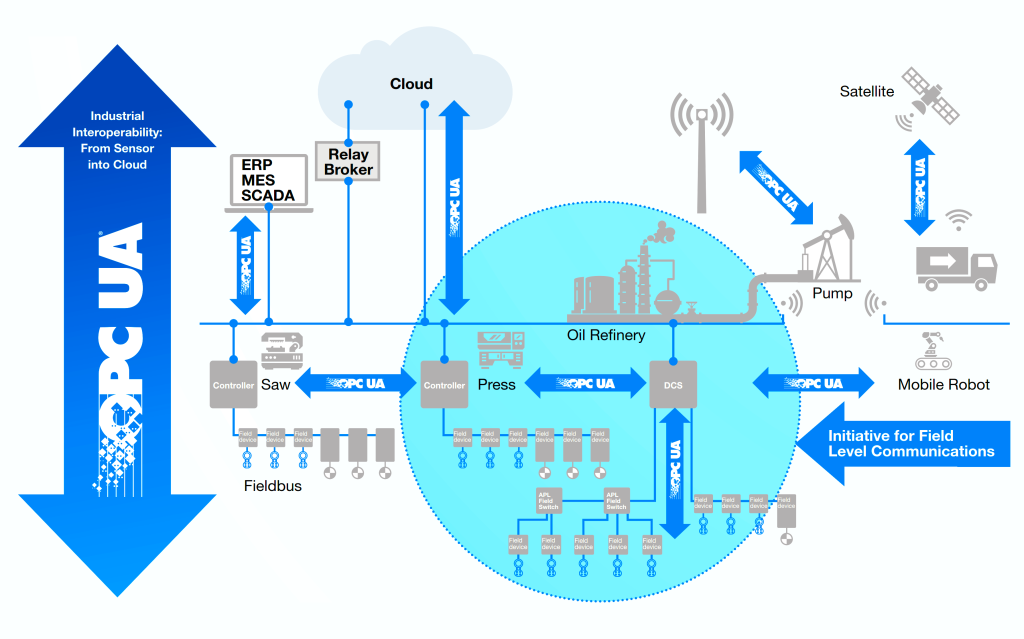

OPC UA stands for Unified Architecture. It’s a platform-independent service-oriented architecture that integrates all the functionality of the individual OPC Classic specifications into one extensible framework.

What is the role of the OPC Configurator?

The OPC Configurator is used to configure the OPC Server. This can include setting up communication parameters and specifying what data should be made available to the OPC Clients.

How does OPC promote interoperability?

OPC promotes interoperability by providing a set of standards that manufacturers can use to ensure their devices are compatible with others. This helps to reduce the risk of devices being incompatible and unable to communicate.

Why is OPC important in industrial automation?

OPC provides a reliable and standardized communication interface for industrial automation systems. It allows for the integration of different systems, ensuring smooth and effective operation.

What is COM in relation to OPC?

COM stands for Component Object Model. It’s a Microsoft technology that allows objects to interact across different programs, and it’s the foundation for OPC.

What is DCOM in OPC?

DCOM stands for Distributed Component Object Model. It extends COM to support communication among objects on different computers on a network, and it’s used in OPC for remote communication.

What is the purpose of an OPC Proxy?

An OPC Proxy is used to facilitate communication between an OPC Client and an OPC Server when they can’t communicate directly, such as when they’re on different networks or use different protocols.

How does OPC DA handle data quality?

OPC DA uses a system of quality flags that indicate the status of a particular data point. These flags can show if data is good, uncertain, or bad, providing essential information about the reliability of the data.

How is OPC UA different from OPC DA?

OPC UA integrates all the OPC Classic specifications (including OPC DA) into a single, extensible framework. It’s also platform-independent, meaning it can operate on any system, not just Windows.

What is the role of an OPC Browser?

An OPC Browser is a tool that allows users to view and interact with the data and objects in an OPC Server.

Can you describe the function of OPC Tunneling?

OPC Tunneling is used to facilitate communication between an OPC Client and Server over a network, bypassing DCOM, which can be difficult to configure and maintain.

What are the common challenges with OPC implementation?

Some of the common challenges include managing DCOM security, ensuring data quality, handling network disruptions, and configuring OPC Servers and Clients correctly.

How can OPC security be ensured?

OPC security can be ensured through methods like using firewalls, implementing DCOM security settings, encrypting communications, and using OPC UA, which has built-in security features.

Can you discuss OPC redundancy?

OPC redundancy involves having backup OPC Servers to ensure continuous operation even if the primary server fails. This is crucial in industrial applications where downtime can be costly.

How is OPC used in SCADA systems?

In SCADA (Supervisory Control and Data Acquisition) systems, OPC can be used to facilitate communication between different devices and systems, enabling data exchange and process control.

Can you describe the difference between synchronous and asynchronous communication in OPC?

In synchronous communication, the client waits for the server to respond before continuing. In asynchronous communication, the client can continue doing other tasks without waiting for the server’s response.

What is OPC XML-DA?

OPC XML-DA is a specification that allows OPC data to be exchanged using XML over HTTP. It’s designed for data exchange over the internet and is more firewall-friendly than DCOM.

What are some examples of OPC Clients?

Examples of OPC Clients include SCADA systems, HMI (Human-Machine Interface) software, and custom applications designed to communicate with OPC Servers.

Can you describe the role of the Group in OPC?

A Group in OPC is a collection of items in an OPC Server. They’re used to manage items that need to be updated or polled together.

How does OPC handle data updates?

OPC can handle data updates through polling, where the client requests updates at set intervals, or through subscriptions, where the server sends updates when data changes.

What is OPC AE?

OPC AE stands for Alarms & Events. It’s an OPC specification that handles event-driven (as opposed to continuous) data, like alarms and process changes.

What is OPC DX?

OPC DX (Data eXchange) is a specification for direct data exchange between OPC Servers, without needing an intermediary client.

Can OPC work over the Internet?

Yes, with OPC UA and OPC XML-DA, OPC can work over the Internet. These specifications are designed to work with internet protocols and are more firewall-friendly.

What is the role of the OPC Foundation?

The OPC Foundation is the organization that manages the OPC standards. They provide specifications, test tools, and certification services for OPC products.

Can OPC connect to a database?

Yes, OPC can connect to a database through an OPC Server. The server can write data to the database, and OPC Clients can read this data.

How does OPC deal with real-time data?

OPC DA is specifically designed to handle real-time data. It allows OPC Clients to read and write real-time data from the OPC Server.

What is OPC Compliance Testing?

OPC Compliance Testing is a process conducted by the OPC Foundation to ensure that OPC products meet the OPC specifications and will interoperate correctly with other OPC products.

How does OPC handle data conversion?

OPC Servers handle data conversion. They take data from the hardware in its native format and convert it into a standard format that OPC Clients can understand.

What is OPC Custom Interface?

OPC Custom Interfaces are interfaces that an OPC Server can provide beyond the standard OPC interfaces. They allow for additional functionality that isn’t covered by the standard OPC specifications.

Can you explain how OPC interacts with PLC?

OPC interacts with Programmable Logic Controllers (PLCs) through an OPC Server. The server communicates with the PLC, reads data from it, and makes it available to OPC Clients.

What is an OPC Item?

An OPC Item is a single point of data in an OPC Server. It represents a specific piece of data from the hardware, like a sensor reading or a device status.

How does OPC handle timestamps?

OPC attaches a timestamp to each data value. This indicates when the data was collected, which is critical for tracking changes over time and diagnosing issues.

What are OPC Properties?

OPC Properties provide additional information about OPC Items, like the item’s description, engineering units, or maximum and minimum values.

How does OPC handle error handling?

OPC has a system of error codes that indicate if a request was successful or why it failed. This helps with diagnosing and resolving issues.

Can OPC work with wireless devices?

Yes, OPC can work with wireless devices. As long as the device can communicate with the OPC Server, it doesn’t matter if the connection is wired or wireless.

What is OPC Batch?

OPC Batch is a specification for batch processing in OPC. It provides standards for executing and managing batch processes.

What are the benefits of using OPC UA over OPC Classic?

OPC UA offers several benefits over OPC Classic, including platform independence, improved security features, a unified framework that includes all the functionality of OPC Classic, and better compatibility with modern internet protocols.

How does OPC handle large amounts of data?

OPC can handle large amounts of data through efficient data handlings mechanisms, like subscriptions, where updates are only sent when data changes, and data buffering in the OPC Server.

Can OPC be used in cloud computing?

Yes, OPC, especially OPC UA, can be used in cloud computing. OPC UA’s platform independence and internet compatibility make it well-suited to cloud applications.

What is OPC .NET?

OPC .NET is a set of .NET APIs for OPC communication. It allows developers to create OPC Clients using .NET.

Can OPC work with non-Microsoft systems?

While OPC Classic is based on Microsoft’s COM and DCOM and primarily works on Windows, OPC UA is platform-independent and can work on non-Microsoft systems.

What is an OPC Wrapper?

An OPC Wrapper is software that facilitates communication between OPC DA and OPC UA, allowing them to work together despite using different technologies.

What is the fundamental principle behind OPC communication?

The principle behind OPC communication is interoperability. It aims to enable different industrial automation devices and software to communicate effectively by following a set of standard protocols.

How does OPC improve efficiency in industrial processes?

By enabling communication between various hardware and software, OPC eliminates the need for custom interfaces, thus reducing system complexity and increasing efficiency in data exchange and process control.

Can you describe how OPC interfaces with sensors and actuators in an industrial setting?

OPC interfaces with sensors and actuators through the OPC Server. The server communicates with these devices, reading sensor data and sending commands to actuators, and then makes this data available to OPC Clients.

Can OPC be used in the pharmaceutical industry? If yes, how?

Yes, OPC can be used in the pharmaceutical industry. It can be used for process control, monitoring equipment, managing data from various systems, ensuring regulatory compliance, and more.

What role does OPC play in Industry 4.0?

OPC, particularly OPC UA, plays a crucial role in Industry 4.0 as it provides a standardized means for machine-to-machine communication, interoperability, and data exchange – all key aspects of the Industry 4.0 vision.

What are OPC Namespaces?

OPC Namespaces are used in OPC UA to organize data and ensure the unique identification of objects, variables, and other elements within the OPC Server’s information model.

Can OPC work with IoT devices?

Yes, OPC, especially OPC UA, can work with IoT devices, enabling secure and reliable data exchange between such devices and other systems or applications.

What are the key elements of an OPC XML-DA Schema?

An OPC XML-DA schema includes elements such as Read, Write, and Browse that represent different operations, and complex types like OPCItemProperty, OPCQuality, and OPCError that represent different kinds of data.

Can OPC handle batch processes in industrial automation?

Yes, OPC Batch is a specification specifically designed to handle batch processes. It provides standards for the management and execution of batch processes.

What is an OPC Data Logger?

An OPC Data Logger is a software application that collects and logs data from an OPC Server. The logged data can then be used for analysis, reporting, and other purposes.

How does OPC interface with control systems like DCS or PLC?

OPC interfaces with control systems like DCS or PLC through the OPC Server. The server communicates with these control systems, exchanging data with them, and makes this data available to OPC Clients.

How can OPC be used in predictive maintenance?

OPC can be used in predictive maintenance by providing real-time and historical data that can be analyzed to predict when a piece of equipment might fail or need maintenance.

What is the role of OPC in energy management systems?

In energy management systems, OPC can be used to gather real-time data from various equipment and sensors, enabling the monitoring and optimization of energy use.

What benefits does OPC offer in terms of system integration?

OPC offers several benefits in system integration, including standardization of data exchange, enabling interoperability between different systems, reducing system complexity, and increasing overall system efficiency.

Can OPC work with MES (Manufacturing Execution Systems)?

Yes, OPC can be used to facilitate communication between MES software and the devices and systems it needs to monitor and control.

Can OPC be used for data analysis?

Yes, by providing access to real-time and historical data, OPC can support data analysis. This data can be used to analyze system performance, troubleshoot issues, optimize processes, and more.

What’s the role of OPC in a smart grid system?

In a smart grid system, OPC can facilitate communication and data exchange between various components of the grid, enabling real-time monitoring, control, and optimization of the grid.

Can OPC be used in a distributed control system (DCS)?

Yes, OPC can be used in a DCS to facilitate communication between the DCS software and the devices and systems it needs to monitor and control.

How can OPC support fault detection in industrial processes?

OPC can support fault detection by providing real-time data on system operation. This data can be monitored to detect any anomalies or deviations from the expected performance that might indicate a fault.

Can OPC support remote monitoring and control?

Yes, OPC, especially with OPC UA or OPC Tunneling, can support remote monitoring and control by facilitating secure and reliable data exchange over networks and the internet.

What is an OPC Test Client?

An OPC Test Client is a software tool used to test the functionality of an OPC Server, ensuring that it’s working correctly and adhering to OPC standards.

How does OPC support alarm management in industrial processes?

OPC Alarms & Events (A&E) is a specification that handles event-driven data, like alarms and process changes. This enables effective alarm management in industrial processes.

Can OPC support mobile devices?

Yes, OPC, particularly OPC UA, can support mobile devices. Its platform independence and compatibility with internet protocols make it suitable for use on mobile devices.

What is an OPC Bridge?

An OPC Bridge is a software application that allows direct data exchange between two OPC Servers, bypassing the need for an OPC Client as an intermediary.

Can OPC be used for asset management in industrial settings?

Yes, OPC can facilitate asset management by providing access to real-time and historical data from various systems and devices. This data can be used to monitor asset performance, plan maintenance, and manage asset lifecycle.

How does OPC deal with network failures or interruptions?

OPC has various mechanisms to handle network failures, including data buffering in the OPC Server, automatic reconnection features, and the use of redundant OPC Servers.

Can OPC support condition monitoring in industrial processes?

Yes, OPC can support condition monitoring by providing real-time data on equipment and process conditions. This data can be monitored to detect any changes that might indicate potential issues.

How can OPC support quality control in manufacturing?

OPC can support quality control by providing real-time data on manufacturing processes. This data can be monitored and analyzed to ensure that processes are operating within the required parameters and that product quality is maintained.

Can OPC handle high-speed data?

Yes, OPC, particularly OPC DA, is designed to handle high-speed, real-time data, making it suitable for applications that require rapid data updates.

Can OPC be used for machine learning applications?

Yes, the data provided by OPC can be used in machine learning applications. The real-time and historical data can be used to train and run machine learning models for tasks like predictive maintenance, process optimization, and more.

What are the security features of OPC UA?

OPC UA includes several security features, including encryption for data confidentiality, authentication to verify the identity of clients and servers, authorization to control access to data, and integrity checks to ensure data has not been tampered with.

Can OPC work with ERP (Enterprise Resource Planning) systems?

Yes, OPC can facilitate data exchange between ERP systems and the various devices and systems in a facility, helping to ensure that the ERP system has accurate, up-to-date information.

How does OPC handle redundancy?

OPC handles redundancy through redundant OPC Servers. If one server fails, a backup server can take over, ensuring continuous operation.

Can OPC handle complex data types?

Yes, OPC UA can handle complex data types. It supports structured data types, allowing it to represent complex data structures.

How can OPC help with regulatory compliance in industries?

OPC can help with regulatory compliance by providing accurate, reliable data logging and traceability. This data can be used to demonstrate compliance with regulatory requirements.

Can OPC be used in water and wastewater management systems?

Yes, OPC can be used in water and wastewater management systems to monitor and control various processes, like treatment processes, pumping operations, and more.

How does OPC support virtualization and cloud technologies?

OPC UA, being platform-independent and compatible with internet protocols, can work well with virtualization and cloud technologies. It can be run on virtual machines and cloud platforms, and it can facilitate data exchange over the Internet.

What is OPC Router?

OPC Router is a software application that can route data between OPC Servers, OPC Clients, and other software and systems, facilitating data exchange and interoperability.

How does OPC handle the synchronization of data?

OPC handles data synchronization through its timestamping feature. Each data value is timestamped when it’s collected, which allows data from different sources to be accurately correlated and synchronized.

Can OPC support collaborative robotics applications?

Yes, OPC, particularly OPC UA, can support collaborative robotics applications. It can facilitate data exchange and coordination between robots, other devices, and control software.

What are the uses of OPC in the oil and gas industry?

OPC can be used in the oil and gas industry for applications like process control, equipment monitoring, data logging, alarm management, and more.

Can OPC be used for building automation systems?

Yes, OPC can be used for building automation systems, facilitating communication and data exchange between various building systems like HVAC, lighting, security, and more.

Can OPC work with SCADA systems?

Yes, OPC can be used to facilitate communication between SCADA software and the devices and systems it needs to monitor and control.

How does OPC handle versioning?

OPC has a clear versioning system for its specifications. Each version of a specification is clearly labeled with a version number, and backward compatibility is maintained where possible.

Can OPC support autonomous vehicles?

Yes, OPC UA, with its platform independence and strong security features, can be used in the development of autonomous vehicles, enabling data exchange and coordination between various vehicle systems.

Can OPC support green energy applications?

Yes, OPC can be used in green energy applications to monitor and control various systems, like wind turbines or solar panels, and to manage data from these systems.

What is OPC Publisher?

OPC Publisher is a component of an OPC UA Server that manages subscriptions and sends data updates to OPC UA Clients.

Can OPC handle multi-threading?

Yes, OPC Servers can support multi-threading, allowing them to handle multiple requests in parallel.

How can OPC be used in the food processing industry?

OPC can be used in the food processing industry for monitoring and control of production processes, ensuring quality control, data logging for traceability, and more.

Can OPC support edge computing applications?

Yes, OPC, particularly OPC UA, can support edge computing applications. It can facilitate data exchange between edge devices and other systems or applications, enabling real-time processing and decision-making at the edge of the network.

What problems might occur when integrating OPC into a system?

Some potential problems include compatibility issues between different OPC versions or vendors, network issues affecting data transfer, security vulnerabilities if proper security measures are not implemented, and issues with handling large volumes of data.

How might DCOM configuration problems affect OPC?

DCOM configuration problems can cause issues with OPC Classic communication. These can include difficulties establishing connections, slow performance, or even complete failure of the OPC communication.

What issues might arise when dealing with high-frequency data in OPC?

Issues might include network congestion, difficulties in handling large volumes of data quickly enough or overloading the OPC Server or OPC Clients.

How might firewall settings affect OPC communication?

Firewall settings could block OPC communication, particularly OPC Classic, which uses dynamic port allocation that can be problematic for firewalls. OPC UA typically has fewer firewall issues as it can work well with fixed ports.

What challenges might you encounter when implementing OPC redundancy?

Challenges could include synchronizing data between redundant OPC Servers, managing failover and switchover processes, and ensuring that OPC Clients can successfully reconnect to the backup server when needed.

What problems could arise from a poor-quality network connection in OPC?

A poor-quality network connection could cause slow data transfer, incomplete or lost data, and connection failures in OPC.

What are the common challenges when securing OPC communication?

Challenges could include setting up secure communication channels, managing authentication and authorization, protecting data confidentiality and integrity, and dealing with potential security vulnerabilities in the system.

What difficulties might you encounter when migrating from OPC Classic to OPC UA?

Difficulties could include compatibility issues, needing to update or replace hardware or software, training staff in the new technology, and dealing with any disruptions to operations during the migration process.

What problems might you face when integrating OPC with non-Windows systems?

Problems could include compatibility issues, as OPC Classic is based on Microsoft technologies. OPC UA overcomes these issues as it’s platform-independent.

How might data modeling issues affect OPC UA?

Poor data modeling could make it difficult to effectively organize and access data in OPC UA. It could also affect interoperability if different systems have different interpretations of the data model.

What challenges might arise when implementing OPC in a large-scale, distributed system?

Challenges could include managing network complexities, ensuring data consistency and synchronization across the system, dealing with large volumes of data, and ensuring system performance and reliability.

What problems might arise from improper OPC Server configuration?

Problems could include failed communication with devices, incorrect data values, performance issues, and inability to handle the required number of OPC Clients or data items.

How can multithreading issues affect OPC?

Multithreading issues could cause performance problems or errors in OPC if not handled correctly. They could lead to concurrency issues, such as race conditions, or overloading of the OPC Server.

How might timestamping issues affect OPC data?

Timestamping issues could affect the accuracy and synchronization of OPC data. If timestamps are incorrect or inconsistent, it can make it difficult to correlate data from different sources.

What challenges might you face when scaling OPC to handle more devices or data?

Challenges could include maintaining performance as the volume of data increases, managing network traffic, ensuring data consistency, and managing the increased complexity of a larger system.

How could legacy system compatibility issues affect OPC integration?

Legacy system compatibility issues could make it difficult to integrate OPC, potentially requiring additional hardware or software solutions, custom interfaces, or modifications to the legacy system.

What problems could be encountered when bridging between different OPC specifications?

Problems could include data loss or corruption if the different specifications handle data differently, compatibility issues, and difficulties in maintaining data consistency and synchronization.

How could incorrect OPC Client implementation affect system performance?

Incorrect OPC Client implementation could cause various issues, including incorrect data values, slow performance, failed communication with the OPC Server, and potential impacts on other clients or the server.

What difficulties might arise when implementing OPC in a high-security environment?

Difficulties could include setting up secure communication, managing user authentication and authorization, dealing with potential security vulnerabilities, and ensuring compliance with security regulations or standards.

What problems might be encountered when debugging OPC communication issues?

Problems could include difficulty identifying the cause of the issue due to the complexity of OPC communication, lack of detailed error information, and difficulties in reproducing the issue for debugging.

What challenges could occur when connecting OPC to a database?

Challenges could include managing data formats and conversions, dealing with large volumes of data, ensuring real-time data updates, and maintaining database performance and security.

How could device compatibility issues affect OPC?

Device compatibility issues could cause problems like failed communication with the device, incorrect data values, or limited functionality if the device does not fully support the OPC standards.

How can OPC handle software and hardware malfunctions?

OPC can handle these through its error handling and reporting mechanisms. OPC Clients can receive error codes or status codes from the OPC Server indicating any issues. OPC also supports redundancy to mitigate the impact of hardware malfunctions.

What difficulties can occur when implementing OPC data aggregation?

Difficulties could include managing data consistency and synchronization, dealing with large volumes of data, handling the additional processing load, and ensuring accurate and meaningful aggregation of data.

How might virtualization or cloud deployment issues affect OPC?

Issues could include network latency affecting OPC performance, security vulnerabilities in the cloud, difficulties in managing OPC Server instances in a virtual or cloud environment, and potential compatibility issues with certain virtualization or cloud technologies.

What are some issues that can occur due to improper OPC server sizing?

Issues due to improper OPC Server sizing could include poor performance, inability to handle the required number of OPC Clients or data items, and potential system instability or crashes.

What problems might be encountered when implementing OPC Alarms & Events?

Problems could include managing a large number of alarms, ensuring real-time alarm notification, dealing with alarm flooding, and integrating alarms with other systems or processes.

What challenges might arise when handling time-sensitive data in OPC?

Challenges could include ensuring real-time data updates, managing network latency, synchronizing data from different sources, and handling time-sensitive operations like control actions or alarms.

How can network configuration issues affect OPC?

Network configuration issues could affect OPC by causing slow data transfer, connection issues, or even complete failure of OPC communication. These could be due to issues like incorrect IP settings, network congestion, or firewall restrictions.

What challenges can arise from implementing OPC in a highly distributed environment?

Challenges could include managing network complexities, ensuring data consistency and synchronization across the system, dealing with potential latency or bandwidth issues, and maintaining system performance and reliability.

What challenges could arise when integrating OPC with different IT systems?

Challenges could include compatibility issues, dealing with different data formats or protocols, managing data exchange and synchronization between systems, and maintaining security and performance across all systems.

What difficulties could arise when handling large volumes of historical data in OPC?

Difficulties could include managing data storage, ensuring quick and efficient data access, maintaining data integrity, and dealing with the potential performance impact of handling large volumes of data.

How might synchronization problems affect OPC?

Synchronization problems could cause issues with data accuracy and consistency in OPC. If data from different sources or systems are not correctly synchronized, it can cause problems with data analysis, control actions, and system coordination.

What challenges could arise when implementing security certificate management in OPC UA?

Challenges could include managing the issuance, renewal, and revocation of certificates, ensuring secure storage and handling of certificates, and dealing with any potential security vulnerabilities related to certificate management.

What challenges might occur when integrating OPC with custom or proprietary systems?

Challenges could include compatibility issues and a lack of support for OPC standards.

Read Next: