Yokogawa Centum VP Distributed Control Systems (DCS)

In this article, you will learn the overview of Yokogawa Centum VP distributed control systems (DCS).

Distributed Control Systems

Yokogawa is a Japanese multinational corporation that produces a wide range of industrial automation and control products, including distributed control systems (DCSs). Their flagship DCS is called CENTUM VP, which is an open and integrated control system that can be used to control and automate large and complex processes.

Yokogawa is a leading manufacturer of industrial automation and control systems, including Distributed Control Systems (DCSs). The Yokogawa DCS is a product line of DCSs that is designed to control and monitor industrial processes, such as those found in the oil and gas, power generation, and water treatment industries.

The Yokogawa DCS typically includes a central control unit, called the controller, which acts as the brain of the system, and a network of field devices, such as sensors, actuators, and transmitters that are distributed throughout the process. These field devices are connected to the controller through a communication network, such as Ethernet, or serial communication protocols like Modbus.

One of the advantages of Yokogawa DCS is that it can be configured to fit the specific needs of the application and can be integrated with other systems such as SCADA, historian, MES, and ERP systems.

Some of the features of Yokogawa DCS include:

- High reliability and availability

- Flexibility and scalability

- Advanced process control and optimization

- Cybersecurity

- Remote monitoring and control

- Data management and analysis

- Interoperability and open standards

Yokogawa DCSs are widely used in various applications such as oil and gas, petrochemicals, chemicals, power, water, and pharmaceuticals. Yokogawa provides also a wide range of services such as automation consulting, engineering, and system integration, as well as training, maintenance, and support services to ensure the smooth operation of their systems.

Learn about Yokogawa DCS and SIS Systems – Click Here

Yokogawa DCS Evolution

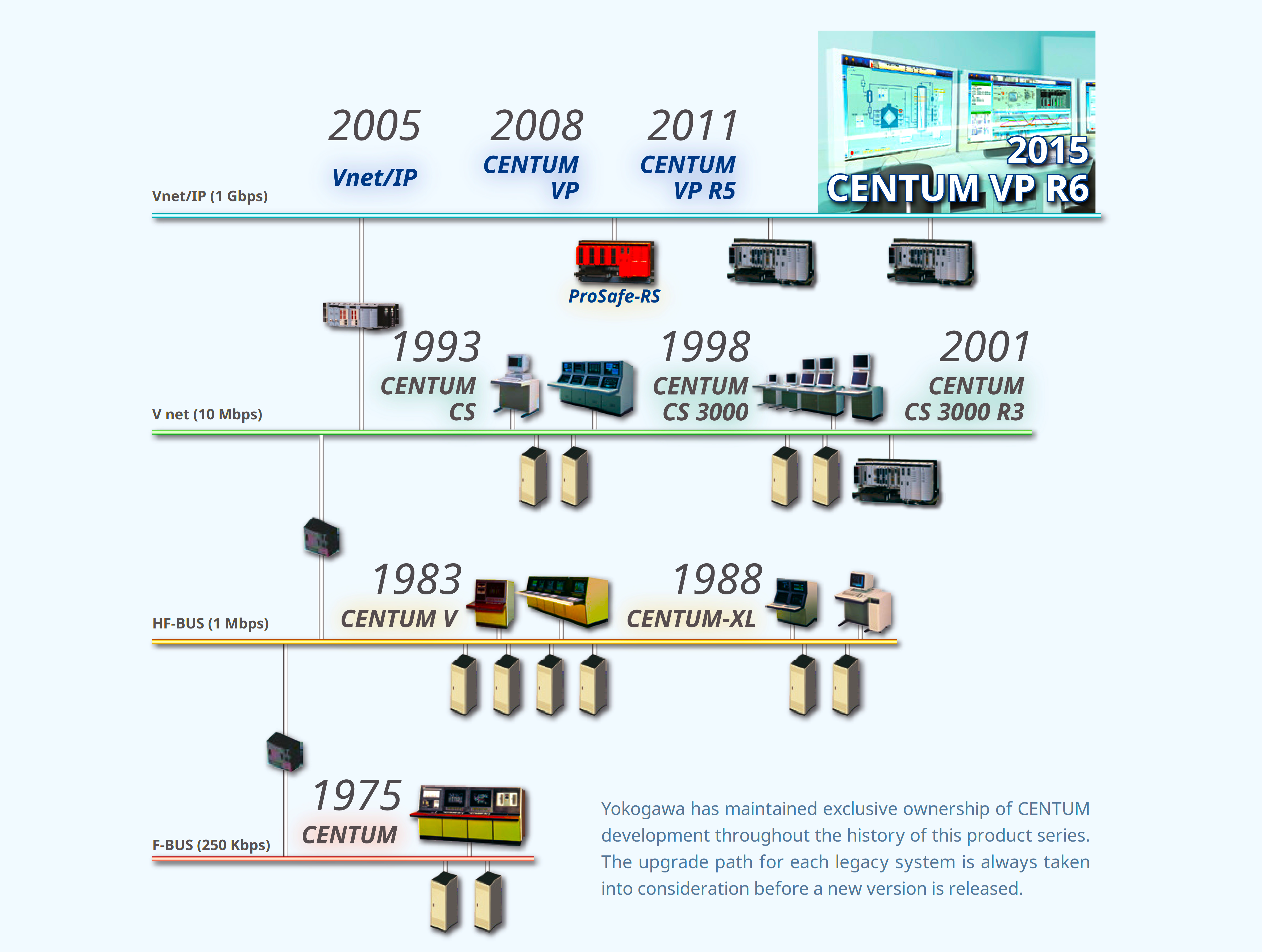

Yokogawa is a Japanese multinational corporation that has been producing distributed control systems (DCSs) for several decades. The evolution of Yokogawa’s DCSs has been driven by advances in technology and the need to improve process control and automation.

The history of Yokogawa DCS can be divided into several key phases:

- Early DCSs (1970s-1980s): Yokogawa developed its first DCS, called the CENTUM System, in the 1970s. It was a proprietary system that used analog technology to control large and complex processes.

- Digital DCSs (1980s-1990s): Yokogawa began to develop DCSs that used digital technology, such as the CENTUM XL and CENTUM CS systems. These systems provided improved process control and automation capabilities.

- Integrated control and safety systems (1990s-2000s): Yokogawa developed an integrated control and safety system called the ProSafe-RS. This system provided advanced safety and control capabilities for critical processes.

- Open architecture DCSs (2000s-current): Yokogawa began to develop DCSs that use open architecture, such as the CENTUM VP system. This allowed for easy integration with other systems and improved flexibility.

- Advanced control and optimization (2000s-current): Yokogawa began to incorporate advanced control algorithms, such as model predictive control (MPC) and artificial intelligence (AI), to improve process control and optimization.

- Cybersecurity (current-future): Yokogawa has been focusing on the integration of cybersecurity measures to protect its DCSs against cyber-attacks.

- Mobility and remote access (current-future): Yokogawa is developing mobile applications and cloud-based technologies to provide new opportunities for remote monitoring and control of processes.

As technology continues to evolve, Yokogawa’s DCSs are likely to become even more sophisticated, with improved control algorithms, and better connectivity, security, and mobility options.

Yokogawa Centum VP DCS

The architecture of a Distributed Control System (DCS) from Yokogawa is typically based on a distributed, multi-level structure.

The Yokogawa DCS architecture typically includes the following components:

- Controllers: The controllers are the processing units that perform the control and monitoring functions of the DCS. They are responsible for collecting data from field devices, processing the data, and generating control signals.

- Network: This connects the controllers and the central computer and allows them to communicate with each other. Yokogawa’s DCS uses a redundant, high-speed network to ensure reliable communication between controllers and the HMI.

- I/O (input/output) devices: These are used to interface with the process and include sensors, actuators, and other devices that provide input to the system and receive output from the system. Yokogawa’s DCS supports a wide range of I/O devices, including digital and analog inputs and outputs, as well as Fieldbus communication protocols.

- Engineering workstations: Engineering workstations are used to configure, program and maintain the Yokogawa DCS system, they are where the engineers will be working on the programming and configuration of the DCS

- Operator interface: The operator interface is the means by which operators interact with the DCS. It typically includes a Human-Machine Interface (HMI) or a graphical user interface (GUI) that provides operators with a real-time view of the process and allows them to make adjustments to the control parameters as needed.

- Database: The database stores the configuration and process data of the DCS. This data can be used for historical trending, reporting, and analysis purposes.

- Field devices: These are the sensors, actuators, and transmitters that are distributed throughout the process and are used to measure and control the process variables. Field devices are connected to the system via communication networks such as Ethernet or serial communication protocols like Modbus.

Some Yokogawa DCSs can be configured to work with different field devices and communication protocols, making them more adaptable and flexible.

List of Yokogawa Software

Yokogawa is a global company that produces a wide range of industrial automation and control products and systems.

Some of their software products include:

- CENTUM VP: A distributed control system (DCS) for large-scale process control applications

- ProSafe-RS: A safety instrumented system (SIS) configuration and programming software

- FAST/TOOLS: A comprehensive suite of software tools for monitoring and controlling industrial processes

- Exaquantum: A plant information management system (PIMS) for collecting, storing, and analyzing process data

- Plant Resource Manager (PRM): A centralized database for managing and maintaining control system configuration and documentation

- Yokogawa Test & Measurement Software: Software for data acquisition, analysis, and control, and software for test and measurement equipment such as oscilloscopes and multimeters

- Data Management Software: Software for data collection, management, and analysis.

- Remote Monitoring and Control Software: Software for remote monitoring and control of industrial processes

- Alarm Management Software: Software for managing and analyzing alarms in industrial processes

- Maintenance Management Software: Software for managing and scheduling maintenance activities in industrial plants.

- Industrial Cybersecurity Software: Software for protecting industrial control systems from cyber threats.

Read Next:

Comments

1

valuable information, thank you.