Distributed Control Systems History and Applications

In this article, you will learn the history and applications of distributed control systems. The popular brands of DCS are listed.

Distributed Control Systems History

The history of distributed control systems (DCSs) dates back to the 1960s and 1970s, when the first DCSs were developed for use in the chemical and petrochemical industries.

During this period, the need for more advanced control systems to automate and control large and complex processes became apparent. Traditional hardwired control systems, which relied on a central control room and analog control devices, were becoming increasingly difficult and costly to maintain.

In response to this, companies began to develop new control systems that used digital technology and distributed control elements, such as controllers, to control processes. These systems were known as distributed control systems (DCSs).

The first DCSs used proprietary hardware and software and were developed by companies such as Honeywell and Yokogawa. They were primarily used in the chemical and petrochemical industries to control large and complex processes, such as chemical reactors and oil refineries.

In the 1980s and 1990s, DCSs began to evolve and improve, with the development of new technologies such as advanced programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems. DCSs also began to be used in other industries, such as power generation, water treatment, and manufacturing.

In the 2000s, DCSs continued to evolve with the advent of new technologies such as Ethernet and the Internet, which allowed for remote monitoring and control of processes. DCSs also began to incorporate advanced control algorithms and data analysis capabilities to improve process control and optimization.

Today, DCSs are widely used in many industries to control large and complex processes and are considered to be one of the most advanced and sophisticated control systems available.

DCS Brands List

There are several major brands that produce and sell distributed control systems (DCSs), including:

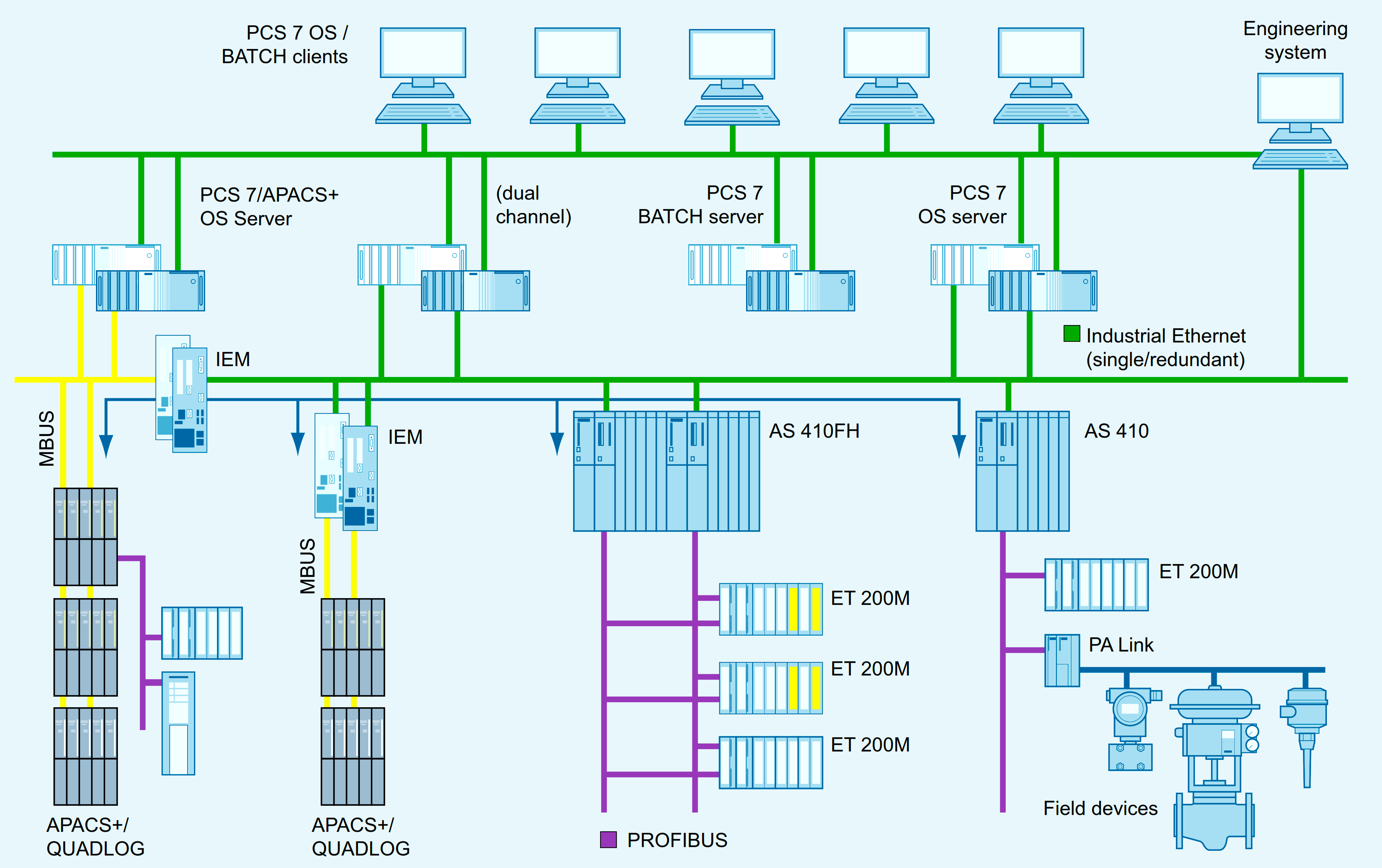

- Siemens: Siemens is a German multinational corporation that produces a wide range of industrial automation and control products, including DCSs. Their DCS is called Simatic PCS 7.

- Yokogawa: Yokogawa is a Japanese multinational corporation that produces a wide range of industrial automation and control products, including DCSs. Their DCS is called CENTUM VP.

- ABB: ABB is a Swedish-Swiss multinational corporation that produces a wide range of industrial automation and control products, including DCSs. Their DCS is called ABB Ability System 800xA.

- Honeywell: Honeywell is an American multinational corporation that produces a wide range of industrial automation and control products, including DCSs. Their DCS is called Experion.

- Rockwell Automation: Rockwell Automation is an American multinational corporation that produces a wide range of industrial automation and control products, including DCSs. Their DCS is called PlantPAx.

- Schneider Electric: Schneider Electric is a French multinational corporation that produces a wide range of industrial automation and control products, including DCSs. Their DCS is called Foxboro Evo.

- Emerson: Emerson is an American multinational corporation that produces a wide range of industrial automation and control products, including DCSs. Their DCS is called DeltaV.

Applications of DCS

Distributed Control Systems (DCSs) are widely used in a variety of industrial and infrastructure applications to control and automate complex processes.

Some examples of applications of DCS include:

- Power generation: DCSs are used to control and monitor power generation processes, such as coal-fired, gas-fired, and nuclear power plants. They are used to control and monitor the process variables such as temperature, pressure, flow, and level, to ensure the safe and efficient operation of the power plant.

- Oil and gas: DCSs are used to control and monitor processes in the oil and gas industry, such as drilling, refining, and petrochemical production. They are used to control and monitor the process variables such as pressure, flow, and level, to ensure the safe and efficient operation of the process.

- Water treatment: DCSs are used to control and monitor processes in water treatment plants, such as water purification, desalination, and wastewater treatment. They are used to control and monitor the process variables such as flow, pH, and temperature, to ensure the safe and efficient operation of the process.

- Pharmaceuticals and biotech: DCSs are used to control and monitor processes in the pharmaceutical and biotech industry, such as fermentation, distillation, and purification. They are used to control and monitor the process variables such as temperature, pH, and pressure, to ensure the safe and efficient operation of the process.

- Manufacturing: DCSs are used to control and monitor processes in manufacturing, such as assembly lines, robotic systems, and packaging systems. They are used to control and monitor the process variables such as temperature, pressure, flow, and level, to ensure the safe and efficient operation of the process.

- Infrastructure: DCSs are also used to control and monitor processes in infrastructure, such as traffic control systems, building automation systems, and transportation systems. They are used to control and monitor the process variables such as temperature, pressure, flow, and level, to ensure the safe and efficient operation of the process.

Read Next: