Advantages and Disadvantages of DCS

In this article, you will learn the advantages and disadvantages of DCS (Distributed Control Systems).

Advantages of DCS

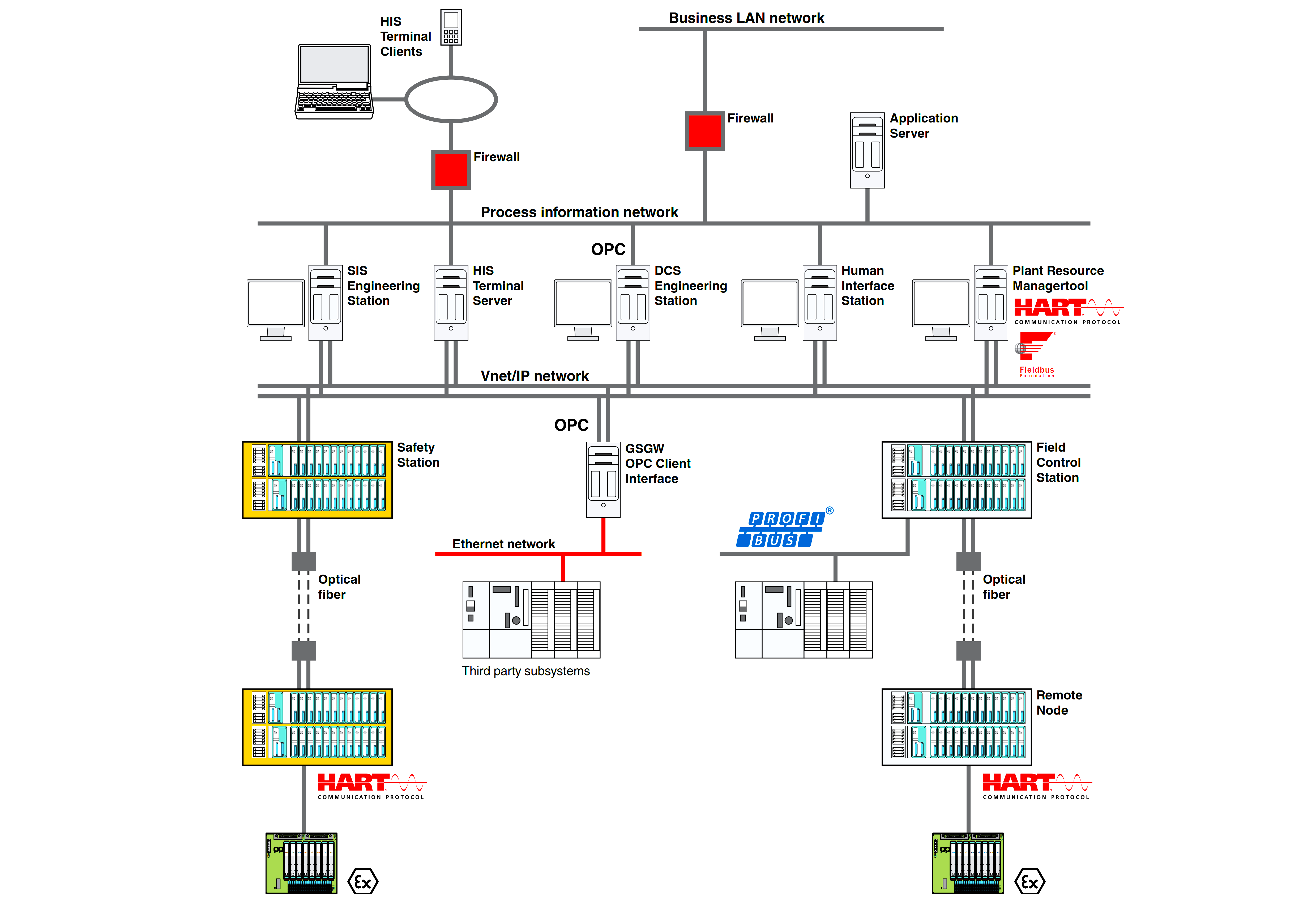

A distributed control system (DCS) is a type of control system that uses decentralized controllers to control a complex process plant.

DCSs have several advantages over other types of control systems, including:

- Improved process control: DCSs use advanced control algorithms, such as PID control, to provide precise and accurate control of processes.

- Scalability: DCSs can be easily expanded to control larger and more complex processes.

- Remote access: DCSs can be accessed remotely using a computer or mobile device, which allows for remote monitoring and control of processes.

- Redundancy: DCSs often have redundant components, such as controllers and servers, which improves the system’s reliability and helps to prevent downtime.

- Flexibility: DCSs can be easily configured to control a wide range of processes and can be used with a variety of input and output devices.

- Improved data collection and analysis: DCSs can collect and store large amounts of process data, which can be used for analysis and process optimization.

- Improved safety: DCSs can be used to implement safety interlocks and alarms to improve the safety of processes.

- Integration: DCSs can be easily integrated with other systems, such as SCADA systems, PLCs, and MES systems, to provide a comprehensive control and monitoring solution.

- Easy Maintenance: DCSs often have a modular design, which makes it easy to maintain, upgrade or replace parts of the system.

- Cost-effective: DCSs are cost-effective solutions for automating and controlling large and complex processes, they are more cost-effective than traditional hardwired control systems.

Disadvantages of DCS

While distributed control systems (DCSs) have many advantages, they also have some disadvantages, including:

- High initial cost: DCSs can be expensive to purchase, install, and maintain.

- Complexity: DCSs can be complex systems with many components, which can make them difficult to understand and operate.

- Training: DCSs require specialized training to operate and maintain, which can be costly.

- Dependency on software and hardware: DCSs rely on software and hardware components, which can make them vulnerable to software bugs and hardware failures.

- Network dependency: DCSs rely on networks to communicate between controllers and servers, if the network goes down the entire system will not work.

- Cybersecurity: DCSs are vulnerable to cyber attacks, which can cause the system to malfunction or shut down.

- Limited compatibility: DCSs are not always compatible with other systems, which can make it difficult to integrate them into existing processes.

- Limited scalability: Some DCSs have limited scalability, which can make it difficult to expand the system as the process grows.

- Limited data visualization: DCSs may not have advanced data visualization capabilities, which can make it difficult to analyze and understand process data.

- Limited mobility: Some DCSs have limited mobility, which can make it difficult to access and control the system remotely.

Read Next:

Comments

1

Good job!