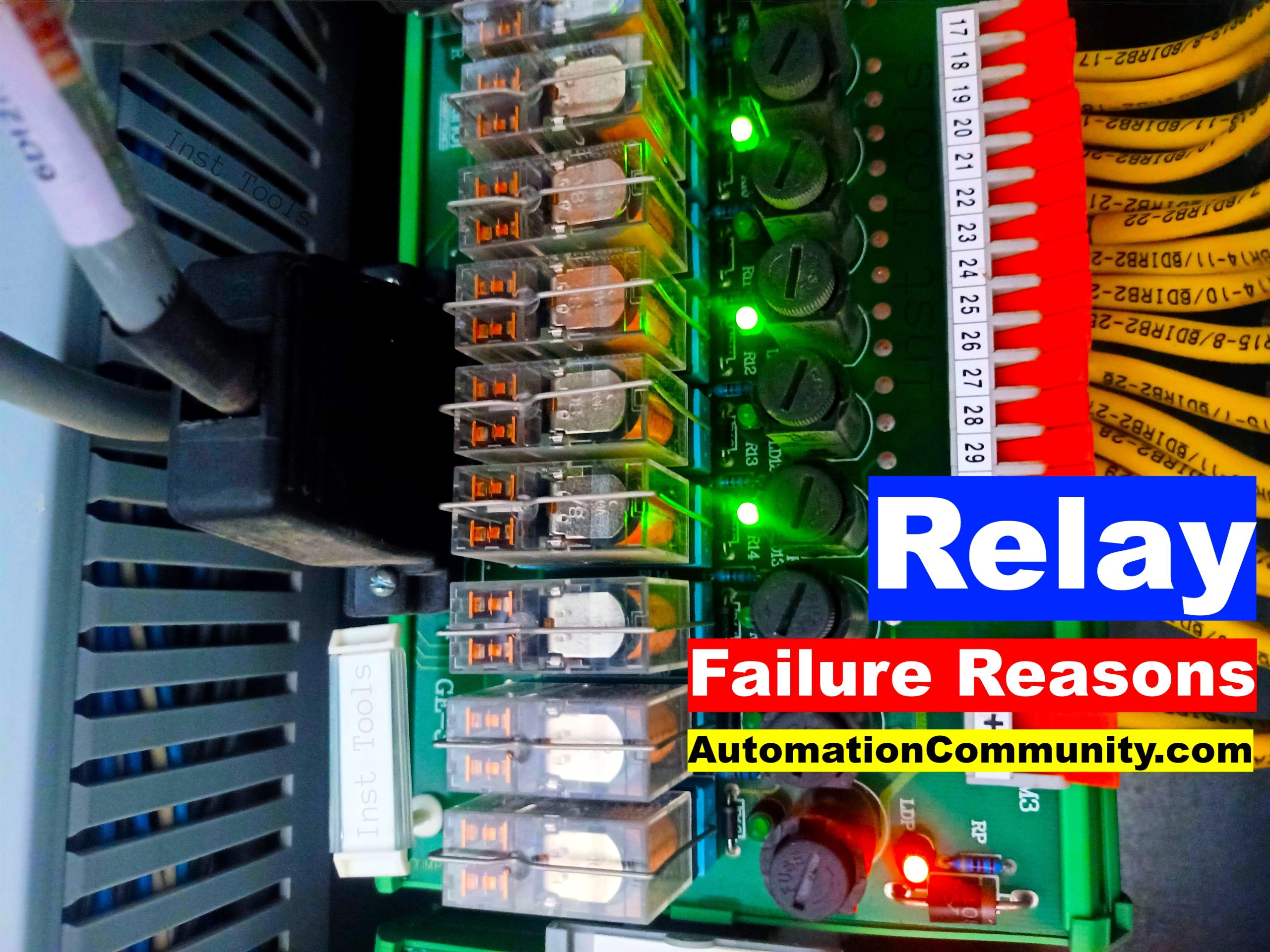

What are the Most Common Relay Failure Reasons?

In this article, you will learn the most common relay failure reasons and how to avoid frequent relay problems.

Most Common Relay Failure Reasons

There are several reasons why a relay may fail, including:

- Excessive current or voltage: A relay may fail if it is exposed to excessive current or voltage, which can burn out the contacts or damage the coil.

- Mechanical wear and tear: Relays that are used frequently can experience mechanical wear and tear, which can cause the contacts to wear out or the actuator to fail.

- Environmental factors: Environmental factors such as temperature, humidity, vibration, and dust can cause a relay to fail.

- Poor quality or manufacturing defects: Poor quality relays or relays with manufacturing defects may be more prone to failure.

- Aging: Relays have a limited life span and will eventually fail, due to aging.

- Overheating: Relays that are placed in an environment with high temperature, or used in an application that generates a lot of heat, may experience overheating and failure.

- Misapplication: Relays that are used in applications for which they are not designed, such as high-frequency switching or high-temperature environments, may fail.

- Lack of maintenance: Some relays require regular maintenance such as cleaning, adjustment, or lubrication to ensure proper operation. If this is not done, the relay may fail.

- Corrosion: Exposure to moisture or chemicals can cause corrosion, which can lead to relay failure.

How to Avoid The Most Common Relay Problems?

There are several steps that can be taken to avoid the most common relay problems:

- Choose the right relay for the application: Make sure to select a relay that is rated for the voltage, current, and environmental conditions that it will be exposed to in the application.

- Properly wire the relay: Make sure that the relay is wired correctly and that the connections are clean and secure.

- Use a properly sized control circuit: Make sure that the control circuit used to activate the relay is properly sized and that the voltage and current levels are within the specified range for the relay.

- Avoid overloading the relay: Make sure that the relay is not being asked to switch more current or voltage than it is rated for.

- Avoid mechanical stress: Make sure that the relay is mounted in a secure location and is not exposed to excessive vibration or shock.

- Regular maintenance: Some relays require regular maintenance such as cleaning, adjustment, or lubrication to ensure proper operation. Make sure to follow the manufacturer’s recommendations for the maintenance of the relay.

- Avoid using the relay beyond its life: Relays have a limited lifespan and will eventually fail. Keep an eye on the usage and environmental conditions and consider replacing the relay if it’s close to the end of its life.

- Avoid modifying the relay: Modifying the relay can affect its performance, which might lead to problems. If a modification is needed, consult the manufacturer or a professional to do it in a safe and professional way.

By following these steps, you can help ensure that your relay is functioning properly and that it will last as long as possible. It’s always good to consult the relay manufacturer’s documentation for specific recommendations for avoiding problems and ensuring a long life for the relay in your specific application.

Read Next: