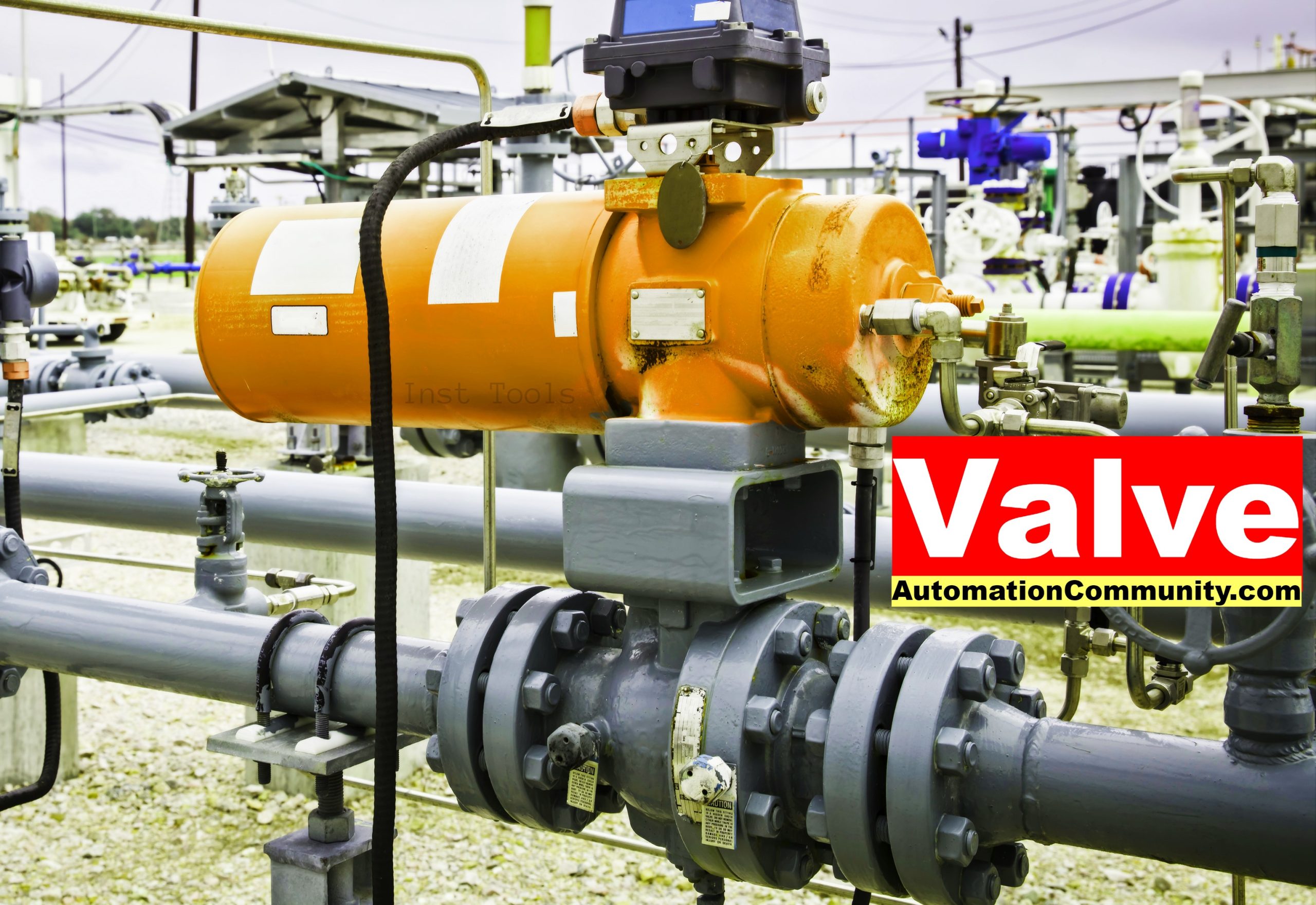

14 Valve Questions

We will learn the top 14 valve questions and answers related to control valve calibration, characteristics, and parameters.

Valve Questions

In valve calibration, what is the purpose of measuring the travel of a control valve?

a) To determine the valve’s operating range

b) To estimate the valve’s frictional losses

c) To calculate the valve’s installed characteristic

d) To verify the valve’s response time

Answer: a) To determine the valve’s operating range

Explanation: Measuring the travel of a control valve helps determine the range of movement the valve can achieve during operation. This information is essential for establishing the valve’s operating parameters and ensuring it can effectively control the fluid flow within the desired range.

Which instrument is commonly used to measure the travel of a control valve during calibration?

a) Positioner

b) Transducer

c) Manometer

d) Flowmeter

Answer: a) Positioner

Explanation: A positioner is a device commonly used to measure and control the travel of a control valve during calibration. It helps accurately position the valve’s stem or actuator based on the control signal it receives, allowing for precise control of fluid flow.

During valve calibration, what does the term “deadband” refer to?

a) The range of valve travel where no response occurs

b) The area where the control signal has no effect

c) The difference between setpoint and actual valve position

d) The zone in which the valve’s hysteresis is most prominent

Answer: b) The area where the control signal has no effect

Explanation: Deadband refers to the range of valve travel where the control signal has no effect on the valve’s position. It represents a zone of inactivity in the control system, where changes in the control signal do not result in any movement or response from the valve.

What is the purpose of a leak test during valve calibration?

a) To ensure the valve’s response time is within specifications

b) To assess the valve’s frictional losses

c) To measure the valve’s installed characteristic

d) To verify the valve’s tightness and sealing integrity

Answer: d) To verify the valve’s tightness and sealing integrity

Explanation: During valve calibration, a leak test is conducted to verify the valve’s tightness and sealing integrity. This test aims to ensure that the valve does not have any leaks or potential points of leakage that could affect its performance and compromise the control system’s efficiency and accuracy.

Which type of actuator is commonly used in control valves?

a) Pneumatic actuator

b) Electric actuator

c) Hydraulic actuator

d) Manual actuator

Answer: a) Pneumatic actuator

Explanation: Pneumatic actuators are commonly used in control valves due to their quick response, reliability, and suitability for various industrial applications. These actuators use compressed air to control and position the valve, making them widely employed in control systems.

What is the purpose of bench set calibration for control valves?

a) To calibrate the valve’s response time

b) To measure the valve’s installed characteristic

c) To verify the valve’s leak tightness

d) To set the valve’s operating range

Answer: d) To set the valve’s operating range

Explanation: Bench set calibration is performed to set the operating range of a control valve. This calibration process involves adjusting the valve’s stem or actuator position to correspond with specific control signals, ensuring that the valve operates within the desired range for optimal control of fluid flow.

Which characteristic of a control valve relates to the change in flow rate with respect to a change in valve position?

a) Gain

b) Deadband

c) Hysteresis

d) Installed characteristic

Answer: d) Installed characteristic

Explanation: The installed characteristic of a control valve describes the relationship between the valve’s position and the resulting change in flow rate. It illustrates how the flow rate varies in response to adjustments in the valve’s position. Understanding the installed characteristic is crucial for accurate control system design and calibration.

During valve calibration, what does the term “repeatability” refer to?

a) The ability of the valve to consistently achieve the same position for the same control signal

b) The degree of accuracy in measuring the valve’s travel

c) The capability of the valve to respond quickly to changes in the control signal

d) The ability of the valve to maintain a stable flow rate

Answer: a) The ability of the valve to consistently achieve the same position for the same control signal

Explanation: Repeatability in valve calibration refers to the valve’s ability to consistently reach the same position when subjected to the same control signal. It ensures that the valve responds predictably and reliably, allowing for precise control of fluid flow based on the control system’s input signals.

What is the purpose of a stroking test during valve calibration?

a) To verify the valve’s response time

b) To measure the valve’s installed characteristic

c) To assess the valve’s frictional losses

d) To ensure smooth and consistent valve movement

Answer: d) To ensure smooth and consistent valve movement

Explanation: A stroking test is conducted during valve calibration to ensure that the valve moves smoothly and consistently throughout its entire range of travel. It helps identify any irregularities or sticking points that may affect the valve’s performance and control system stability.

What does the term “stem packing” refer to in valve calibration?

a) The sealing material used in the valve stem

b) The protective coating applied to the valve body

c) The measurement of valve stem travel

d) The positioner used to control the valve’s stem movement

Answer: a) The sealing material used in the valve stem

Explanation: Stem packing in valve calibration refers to the sealing material used to prevent leakage along the valve stem. It ensures a tight seal between the stem and the valve body, maintaining the integrity of the control system and preventing fluid leakage.

Which type of calibration curve is typically associated with equal percentage control valves?

a) Exponential

b) Linear

c) Logarithmic

d) Step

Answer: a) Exponential

Explanation: Equal percentage control valves exhibit an exponential calibration curve. This means that for equal increments of valve position, there is a consistent percentage change in the flow rate. It allows for more precise control at lower flow rates while still accommodating higher flow rates.

Which type of control valve characteristic is commonly associated with quick opening valves?

a) Linear

b) Parabolic

c) Hyperbolic

d) Sigmoidal

Answer: b) Parabolic

Explanation: Quick opening valves are characterized by a parabolic control valve characteristic. This means that the flow rate increases rapidly initially with small valve position changes and then gradually approaches linearity as the valve opens further.

Which type of actuator is commonly used in control valves requiring high thrust and precision?

a) Pneumatic actuator

b) Electric actuator

c) Hydraulic actuator

d) Manual actuator

Answer: b) Electric actuator

Explanation: Electric actuators are commonly used in control valves that require high thrust and precision. These actuators offer precise positioning control and can generate substantial force, making them suitable for applications that demand accurate and powerful valve operation.

What does the term “backlash” refer to in valve calibration?

a) The difference between setpoint and actual valve position

b) The non-linear response of a valve

c) The zone where no valve movement occurs

d) The mechanical play or looseness in the valve mechanism

Answer: d) The mechanical play or looseness in the valve mechanism

Explanation: Backlash in valve calibration refers to the mechanical play or looseness present in the valve mechanism. It causes a delay or deadband in valve movement, where the valve does not respond immediately to changes in the control signal. Minimizing backlash is crucial for improving the valve’s accuracy and control system performance.

What does the term “bench range” refer to in valve calibration?

a) The maximum allowable flow rate through the valve

b) The distance traveled by the valve during calibration

c) The range of the control signal applied to the valve during calibration

d) The allowable deviation from the setpoint in valve operation

Answer: c) The range of the control signal applied to the valve during calibration

Explanation: Bench range in valve calibration refers to the range of the control signal that is applied to the valve during the calibration process. It represents the span of control over which the valve’s movement and response are evaluated to ensure accurate and effective control system operation.

Read Next: