Level Sensors and Transmitters Questions and Answers

Level Sensors and Transmitters are crucial components in numerous industrial processes, playing an essential role in maintaining optimal operations by precisely measuring and controlling the level of liquids, granular, or slurries within a specified space. Understanding their principles, types, applications, and nuances is key for professionals in instrumentation and control systems.

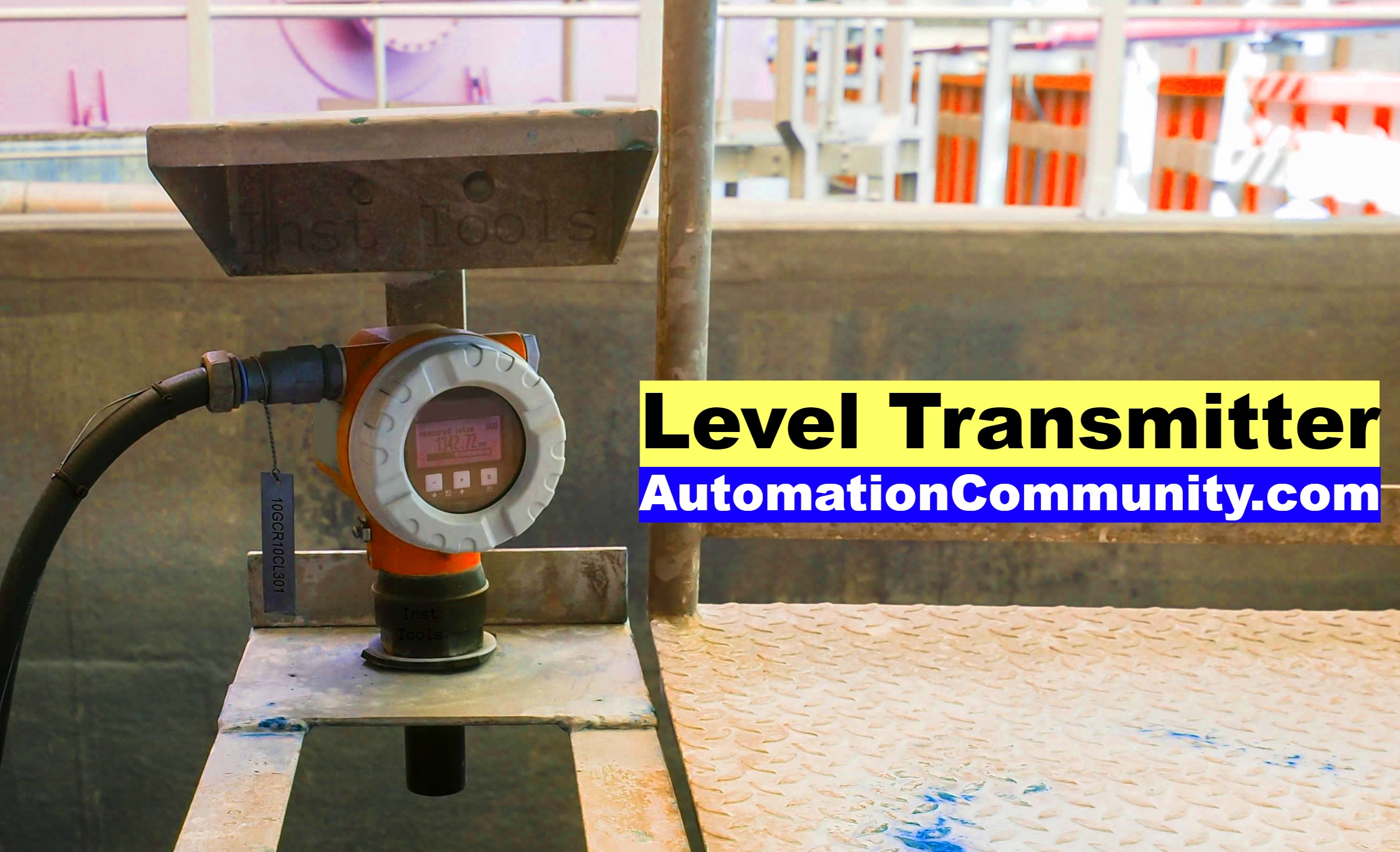

Level Sensors and Transmitters

Level Sensors and Transmitters Questions and Answers help you to learn key concepts, operation principles, and various types of level measurement technologies. This guide is an invaluable resource for anyone studying or working in the field of process instrumentation and control.

Can you explain what a level transmitter is?

A level transmitter is a device that measures the level of a fluid or solid material within a container, such as a tank, silo, or other storage vessel. It generates a signal that corresponds to the level of the material, and this signal is used by control systems to monitor or regulate the level.

Can you describe the two types of level measurement?

Yes, there are direct level measurements and indirect level measurements. Direct measurement involves observing the actual height of the substance, while indirect measurement infers the level based on other parameters like pressure or temperature.

What are some common applications for level transmitters?

Level transmitters are used in a variety of industries such as oil and gas, water treatment, food and beverage, pharmaceuticals, and energy. They are often used to monitor the levels of liquids, granulars, slurries, and interfaces in tanks, silos, and hoppers.

Can you explain how a radar-level transmitter works?

A radar-level transmitter emits radio waves toward the surface of the material. These waves reflect back to the transmitter. By calculating the time it takes for the waves to return, the transmitter can determine the distance and, therefore, the level of the material.

What is the difference between a contact and a non-contact level transmitter?

Contact level transmitters are in direct contact with the material they are measuring, like float level transmitters. Non-contact level transmitters do not come into contact with the material, such as radar and ultrasonic level transmitters.

What is the principle behind ultrasonic-level transmitters?

Ultrasonic level transmitters work on the principle of time of flight. They emit an ultrasonic pulse toward the material. This pulse reflects back to the transmitter, and by calculating the time it took for the pulse to return, the transmitter can determine the level.

Why might a company choose a guided wave radar level transmitter?

Guided wave radar level transmitters are a good choice when dealing with heavy dust, vapor, or turbulent surface. They also perform well in narrow tanks or with complex internal structures.

What is the role of a differential pressure transmitter in level measurement?

Differential pressure transmitters measure the pressure difference at two points in a tank. This pressure difference can be used to calculate the level of the liquid in the tank.

How would you troubleshoot a faulty level transmitter?

Troubleshooting a level transmitter involves checking the power supply, wiring, the condition of the sensor, and the output signal. One would also need to check the configuration settings and make sure they are correct for the specific application.

What is the significance of the dielectric constant in radar level measurement?

The dielectric constant is a measure of a material’s ability to store electrical energy in an electric field. In radar level measurement, it affects the reflection of the radar waves. If the dielectric constant is too low, the radar signal may not reflect back adequately.

Can you explain the working principle of a float-level transmitter?

A float-level transmitter uses a float that moves up and down with the level of the material. The float movement is usually converted into a signal, like electrical resistance, which can be used to determine the level.

Can a capacitive-level transmitter be used for both conductive and non-conductive materials?

Yes, capacitive-level transmitters can be used for both conductive and non-conductive materials. The dielectric constant of the material can affect the sensitivity and accuracy, so it must be considered during configuration.

What are the factors that can affect the accuracy of a level transmitter?

Factors such as temperature changes, pressure variations, buildup on the sensor, dielectric constant changes, and changes in the material’s properties can affect the accuracy of a level transmitter.

What is the principle behind a magnetostrictive level transmitter?

A magnetostrictive level transmitter uses a magnetic field to generate a sonic pulse in a wire. This pulse is reflected by a float that moves with the level. By measuring the time for the pulse to return, the transmitter can determine the level.

How can you prevent build-up on level transmitter sensors?

Regular cleaning and maintenance can help prevent build-up. Choosing the right type of level transmitter for the application can also help, as some types are less prone to build-up than others.

What is the role of HART communication in level transmitters?

HART (Highway Addressable Remote Transducer) is a communication protocol widely used with level transmitters. It allows for two-way field communication, enabling the device to send and receive data. It’s useful for remote monitoring, diagnostics, and calibration.

Why is a 4-20mA signal commonly used in level transmitters?

The 4-20mA signal is used as it’s less susceptible to electrical noise, allowing for reliable transmission over long distances. It also provides a ‘live zero’ at 4mA, meaning that a reading of zero current often indicates a fault in the system.

What is the benefit of using a two-wire level transmitter?

Two-wire level transmitters are easier to install and require less wiring. The two wires carry both the power supply and the output signal, reducing complexity and installation cost.

Can you explain what an interface-level transmitter is and when it is used?

Interface level transmitters are used when you need to measure the interface between two immiscible liquids with different densities, like oil and water. They can determine both the overall level and the level of the interface.

How does temperature affect the level measurement?

Temperature can affect the density of the material and the propagation speed of the measurement signal (like radar or ultrasonic waves). It can also cause physical changes to the vessel which could affect the measurement.

What is the use of a displacer-level transmitter?

Displacer-level transmitters work on Archimedes’ principle. They are typically used in rugged applications with high temperatures, pressures, and corrosive materials. The displacer is not affected by changes in material properties like dielectric constant or conductivity.

How does pressure affect the level measurement?

Pressure changes can affect the density of the material, which can influence level measurement. For certain methods like differential pressure level measurement, the pressure directly affects the reading.

How would you calibrate a level transmitter?

Calibration typically involves adjusting the transmitter’s output to match known reference points. This could involve filling the tank to specific levels and adjusting the output to match, or using a simulation device to simulate different levels.

What are the advantages and disadvantages of an ultrasonic-level transmitter?

Advantages include non-contact measurement, versatility in application, and suitability for hazardous locations. Disadvantages include potential interference from obstacles, changes in material properties, and ambient conditions like temperature and humidity.

Can you explain the function of a tuning fork-level transmitter?

Tuning fork-level transmitters work on the principle of resonance. The forks vibrate at their natural frequency and when material covers the forks, the frequency changes. This change can be used to detect the level of the material.

What is the benefit of a submersible-level transmitter?

Submersible level transmitters are able to directly measure the hydrostatic pressure of a fluid, thus offering accurate level measurement even in deep tanks or wells. They are typically robust, waterproof, and can be used in a variety of conditions.

What are some of the safety considerations when using level transmitters?

Safety considerations can include ensuring the transmitter is suitable for the type of material and conditions, regular maintenance to ensure proper operation, and the use of safety barriers or isolators for transmitters used in hazardous areas.

What is the impact of agitated or turbulent surfaces on level measurement?

Agitated or turbulent surfaces can make level measurement more challenging. For example, they can interfere with the measurement signal in non-contact methods like radar and ultrasonic. Some types of level transmitters, like guided wave radar, are better suited to handle these conditions.

How can we measure the level of solid materials like grains or powders?

Non-contact methods like radar and ultrasonic are commonly used for solid materials. However, the angle of repose, dust, and other factors can complicate measurement. Special techniques like using multiple transmitters or 3D mapping can help improve accuracy.

Can you explain the term ‘dead band’ in ultrasonic-level transmitters?

The ‘dead band’ is a zone close to the ultrasonic transmitter where it cannot accurately detect the level. This is due to the fact that the emitted sound wave and the echo overlap in this area.

What is echo loss in radar level measurement?

Echo loss occurs when the radar signal doesn’t reflect back to the transmitter adequately. This could be due to factors like low dielectric constant, angled surfaces, obstructions, or foam.

What do you understand by two-wire and four-wire configurations in level transmitters?

In a two-wire configuration, the same two wires are used for both power supply and signal output. In a four-wire configuration, separate pairs of wires are used for the power supply and signal output.

What is a ‘blind zone’ in level measurement?

A ‘blind zone’ is a region near the sensor where the level cannot be accurately detected. This term is often used with non-contact measurement methods like radar and ultrasonic.

How does an RF capacitance level transmitter work?

An RF (Radio Frequency) capacitance level transmitter works by measuring the change in capacitance caused by the change in level. The sensor and the vessel wall form a capacitor, and as the level changes, the dielectric between them changes, affecting the capacitance.

How does a nuclear-level transmitter work?

A nuclear-level transmitter uses a radioactive source and a detector. The source emits radiation toward the detector. As the level changes, it affects the amount of radiation reaching the detector, allowing the level to be determined.

How does foam affect the level measurement?

Foam can cause problems for many types of level measurement. For example, it can absorb or scatter ultrasonic and radar signals, leading to inaccurate readings. Certain methods, like guided wave radar, are less affected by foam.

Can you explain the use of a laser-level transmitter?

A laser-level transmitter works by emitting a laser beam toward the material. The beam is reflected back to the transmitter, and by measuring the time it takes for the beam to return, the transmitter can determine the level.

What is the significance of beam angle in radar and ultrasonic level measurement?

The beam angle is the angle at which the measurement signal spreads out. A wider beam angle could result in the signal interacting with the vessel walls or other obstructions, leading to inaccurate readings.

How do you compensate for changes in material properties in level measurement?

Many level transmitters have configuration settings that can be adjusted to compensate for changes in material properties. Regular calibration and the use of more sophisticated measurement techniques can also help.

How do you determine the range of a level transmitter?

The range of a level transmitter is determined by the maximum and minimum levels that need to be measured. This is often determined by the physical dimensions of the vessel and the requirements of the process.

What considerations would you make when choosing a level transmitter for a high-temperature application?

The transmitter must be able to withstand the high temperature without its performance or lifespan being significantly affected. You would also need to consider factors like the effect of the high temperature on the material properties and the measurement signal.

What is a point-level transmitter and how does it differ from a continuous-level transmitter?

A point-level transmitter detects if the level has reached a specific point, often used for high or low-level alarms. A continuous level transmitter measures the level throughout the entire range, providing a continuous output signal.

Can you describe the working principle of a pneumatic-level transmitter?

Pneumatic level transmitters, also known as air-bubbler systems, work by applying constant air pressure to a dip tube and measuring the pressure required to create a steady stream of bubbles. This pressure correlates to the fluid level in the tank.

How can you deal with changes in atmospheric pressure in level measurement?

Changes in atmospheric pressure can affect level measurements, especially those based on pressure. Compensation can be done by using a vented reference line or by using a differential pressure transmitter that measures the difference between the pressure at the bottom of the tank and the atmospheric pressure.

Can a level transmitter be used to measure the flow rate?

In certain applications, level transmitters can be used to infer flow rate. For example, in an open channel with known dimensions and characteristics, the level can be used to calculate the flow rate using a suitable flow equation.

How does a vibrating level transmitter work?

Vibrating level transmitters work on the principle of a vibrating element. The vibration frequency changes when the element comes into contact with the material and this change can be used to detect the level.

What is the importance of mounting position in level measurement?

The mounting position can significantly affect the accuracy of level measurement. It must be positioned so that the measurement signal interacts with the material properly, without interference from obstructions, vessel walls, or other factors.

What is a servo-level transmitter and where is it used?

A servo-level transmitter works by using a servo motor to drive a displacer up and down. The force required to maintain the displacer’s position gives a measure of the level. They are often used in applications requiring high accuracy, like in the oil and gas industry.

Can you explain the significance of the dielectric constant in radar-level measurement?

The dielectric constant is a property of materials that affects how well they reflect radar waves. A higher dielectric constant means better reflection and better measurement accuracy. It is an important factor when using radar-level transmitters.

How would you troubleshoot a level transmitter that’s giving inaccurate readings?

Troubleshooting could involve checking the configuration and calibration of the transmitter, inspecting for physical issues like build-up or damage to the sensor, checking the conditions in the tank like temperature and pressure, and checking the electrical connections and signal integrity.

What is the Time of Flight (ToF) principle in level measurement?

The time of Flight (ToF) principle is used in level measurement methods like radar and ultrasonic. It involves sending a signal toward the material and measuring the time it takes for the signal to be reflected back. The time of flight can be used to calculate the distance and hence the level.

How does a microwave-level transmitter work?

Microwave-level transmitters work on a similar principle to radar transmitters. They send out a microwave signal, and the time it takes for the signal to be reflected back is used to determine the level.

What is a guided wave radar (GWR) level transmitter and how does it differ from a non-guided radar transmitter?

A Guided Wave Radar (GWR) transmitter uses a probe to guide the radar signal toward the material. This makes it less affected by factors like foam, turbulence, and obstructions compared to non-guided radar. It can also measure both overall and interface levels.

What do you understand by loop-powered and line-powered level transmitters?

Loop-powered level transmitters are powered by the current loop (typically 4-20mA) that they are connected to, while line-powered transmitters have a separate power supply. Loop-powered transmitters are simpler to install and require less wiring, but they may have limitations in terms of functionality compared to line-powered transmitters.

How does a sight-glass level transmitter work?

A sight glass level transmitter works by providing a visual indication of the level. The sight glass is a transparent tube connected to the tank. Some sight glasses also have magnetic floats and sensors for electronic-level detection.

Can a level transmitter be used to measure the density of a material?

Certain types of level transmitters, like differential pressure and radar, can be used to infer the density of material under specific conditions. However, dedicated density measurement devices would generally provide better accuracy.

How does a differential pressure level transmitter work?

A differential pressure level transmitter measures the pressure difference between two points. In level measurement, it’s typically used to measure the pressure difference between the bottom and top of the tank. This difference is proportional to the level of the material.

What is a magnetic level transmitter and where is it used?

Magnetic level transmitters use a float with a magnet that moves up and down with the level. Sensors outside the tank detect the position of the magnet. They are often used in applications with corrosive or hazardous materials, where it’s beneficial to isolate the sensors from the material.

How do you adjust the span and zero of a level transmitter?

The span and zero adjustments are typically part of the calibration process. The zero is adjusted by ensuring the transmitter reads correctly when the level is at its minimum, while the span is adjusted by ensuring the transmitter reads correctly when the level is at its maximum.

What is the role of a suppressor diode in a level transmitter circuit?

A suppressor diode, or transient voltage suppressor, is used to protect the circuit from voltage spikes. This can be important in level transmitters due to the presence of inductive loads, which can generate voltage spikes when switched off.

How does a thermal level transmitter work?

A thermal level transmitter works by using a heated sensor. The cooling effect of the material on the sensor depends on the level, allowing it to be determined. This method is often used for point-level detection.

How can you deal with buildup on the sensor in level measurement?

Regular maintenance and cleaning can help deal with buildup. Certain types of transmitters are less affected by buildup, like non-contact methods. You can also use special features or techniques, like self-cleaning sensors or air purge systems.

Can you describe the working principle of a hydrostatic level transmitter?

A hydrostatic level transmitter works by measuring the pressure exerted by the material at a certain depth. This pressure is directly proportional to the level of the material.

What is a capacitive level transmitter and where is it used?

A capacitive level transmitter works by measuring the change in capacitance caused by the change in level. The transmitter and the vessel wall form a capacitor, and as the level changes, the dielectric changes, affecting the capacitance. They are often used in applications with liquids and granular materials.

How does a rotating paddle level switch work?

A rotating paddle level switch works by rotating a paddle inside the material. When the level reaches the paddle, it prevents it from rotating. This change in rotation can be used to detect the level.

Can a level transmitter measure both liquid and solid levels?

While many level transmitters can measure both liquid and solid levels, the effectiveness and accuracy may depend on the specific conditions and the type of material. Certain types of transmitters might be better suited for liquids, while others might be better for solids.

What factors affect the accuracy of a level transmitter?

The accuracy of a level transmitter can be affected by a number of factors, including the physical properties of the material, conditions in the vessel like temperature and pressure, the configuration and calibration of the transmitter, and the quality of the measurement signal.

Can a level transmitter be used in a pressurized tank?

Yes, level transmitters can be used in pressurized tanks. However, the pressure must be taken into account in the level measurement. This can often be done by using a differential pressure transmitter that measures the difference between the pressure at the bottom and the top of the tank.

What is a bubbler tube system?

A bubbler tube system, also known as a pneumatic level transmitter, works by applying a constant air pressure to a dip tube and measuring the pressure required to create a steady stream of bubbles. This pressure correlates to the fluid level in the tank.

What is an ultrasonic level transmitter and where is it used?

An ultrasonic-level transmitter works by emitting ultrasonic waves toward the material. The waves are reflected back to the transmitter, and by measuring the time it takes for the waves to return, the transmitter can determine the level. Ultrasonic level transmitters are commonly used in applications with liquids and solids where non-contact measurement is beneficial.

How do you ensure that a level transmitter is installed correctly?

Ensuring the correct installation of a level transmitter involves following the manufacturer’s instructions, considering factors like the mounting position, avoiding obstructions and interference, and ensuring that the electrical connections are correctly made. It also involves testing and calibration to ensure correct operation.

What is the role of a stilling well in level measurement?

A stilling well is a tube or pipe that is installed in the tank to provide a calm area for level measurement. This can help improve the accuracy of certain types of level transmitters, like float or displacer types, in situations where there is turbulence or agitation.

Can you explain the working of a load cell-based level transmitter?

A load cell-based level transmitter works by measuring the weight of the material. The load cells are typically installed under the tank, and as the level changes, the weight changes, allowing the level to be determined.

Can you describe the working principle of an optical level switch?

An optical level switch works by emitting a beam of light from an LED into a prism. When the prism is not submerged, the light is reflected back to a receiver. When the material level rises and the prism is submerged, the light is refracted into the material and less light is reflected back. The switch detects this change in light.

What role does a Hart protocol play in level transmitters?

HART protocol is a communication protocol widely used in industrial automation. In level transmitters, it allows for two-way communication between the device and a control system. This can enable remote configuration, calibration, diagnostics, and access to additional information like device status and diagnostics.

What is an RF-level transmitter?

RF (radio frequency) level transmitters work by emitting a low-power RF signal into the material and detecting the reflected signal. The change in the signal can be used to determine the level. RF transmitters can be used with a variety of materials, including liquids, solids, and sludges.

Can a level transmitter be used to measure interface levels?

Yes, certain types of level transmitters, like guided wave radar and differential pressure, can be used to measure interface levels. These levels are the boundary between two immiscible liquids with different densities.

How would you calibrate a level transmitter?

Calibration typically involves adjusting the transmitter to read correctly at known reference points. For a level transmitter, these reference points would be the minimum and maximum levels. Calibration can be performed using software tools provided by the transmitter manufacturer, or manually by adjusting the transmitter settings.

What type of level transmitter would you use in a corrosive environment?

For corrosive environments, you would need a transmitter that is resistant to corrosion. This could mean using a transmitter with a suitable material of construction, like stainless steel or a specific plastic. Non-contact methods, like radar or ultrasonic, could also be beneficial as they avoid direct contact with the material.

Can you explain the two-wire and four-wire systems in level transmitters?

A two-wire system uses the same wires for power and signal. This is simpler to install but can have limitations in terms of functionality. A four-wire system uses separate wires for power and signal, which can allow for more sophisticated functions and better signal quality.

What is a nuclear-level transmitter and where is it used?

A nuclear-level transmitter uses a radioactive source and a detector. The level is determined by the amount of radiation detected, which depends on the level of the material. They are often used in extreme conditions and with hazardous materials where other methods are not suitable.

What is an invasive level transmitter?

An invasive level transmitter is one that requires contact with the material to measure the level. This can include methods like float, displacer, and hydrostatic pressure. Non-invasive or non-contact methods, like radar and ultrasonic, are often used when contact with the material is undesirable.

Can a level transmitter measure flow rate?

While level transmitters are designed to measure level, they can sometimes be used to infer flow rate under specific conditions. For example, in weirs or flumes, the level can be related to the flow rate. However, dedicated flow measurement devices are generally more accurate for this purpose.

What is a tuning fork level switch?

A tuning fork-level switch works by vibrating a fork-shaped sensor at a specific frequency. When the material level reaches the fork, it changes the frequency of vibration. This change can be used to detect the level.

What do you understand by “false echo” in radar level measurement?

False echo is a term used in radar level measurement to refer to reflections that are not from the actual material level. These can be caused by obstructions in the tank, the tank walls, or other structures. Advanced radar transmitters have algorithms to distinguish the true level echo from false echoes.

How does a vibrating level switch work?

A vibrating level switch works by vibrating a probe at a specific frequency. When the level of the material reaches the probe, it dampens the vibration. This change can be detected and used to determine the level.

What types of level transmitters are typically used in the food and beverage industry?

The food and beverage industry often uses level transmitters that can handle the specific requirements of this industry, like cleanliness and food safety. This can include non-contact methods like radar and ultrasonic, as well as contact methods with suitable materials and designs, like hygienic float switches or pressure transmitters.

How does the level transmitter detect the low and high levels?

The level transmitter detects low and high levels based on its calibration settings. When the signal from the transmitter corresponds to the low or high calibration point, it indicates that the level has reached that point.

Can a level transmitter be used to detect leaks?

While level transmitters are primarily designed to measure level, they can sometimes be used to infer a leak if the level decreases unexpectedly. However, dedicated leak detection systems would generally provide more reliable detection.

What are the advantages and disadvantages of a float-level transmitter?

The advantages of float-level transmitters include simplicity, reliability, and suitability for a variety of applications. Disadvantages can include potential issues with the float mechanism, like sticking or jamming, and limitations in terms of temperature, pressure, and specific gravity of the liquid.

How does a conductive level switch work?

A conductive level switch works by passing a small electrical current through the material. When the level reaches the sensor, it completes the electrical circuit, allowing the current to flow and signaling the level.

What factors would you consider when selecting a level transmitter for a specific application?

When selecting a level transmitter, factors to consider include the type of material, physical properties of the material, conditions in the vessel like temperature and pressure, the required accuracy and resolution, the mounting and installation requirements, and any regulatory or safety requirements.

Read Next: