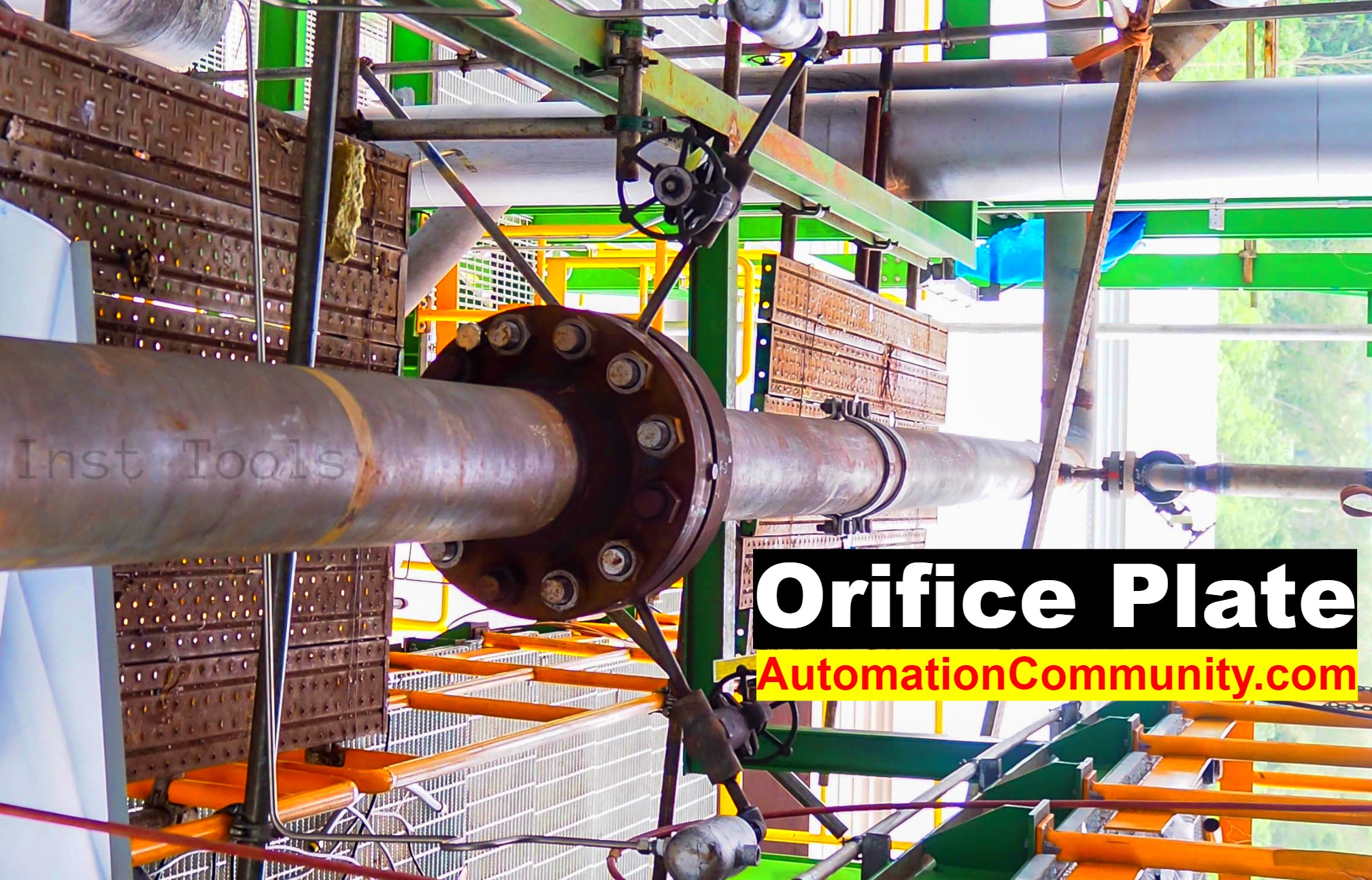

Orifice Plate Questions and Answers

Looking for answers to your orifice plate questions? Dive into our collection of orifice plate questions and answers in instrumentation. Explore a wide range of topics including theory, installation, calculations, and troubleshooting. Expand your knowledge and confidently navigate the world of orifice plates with our reliable Q&A resource.

Orifice Plate Questions

What is an orifice plate?

An orifice plate is a device used in flow measurement. The orifice plate is a thin plate with a hole in the middle and is inserted into a pipe-carrying fluid. The flow rate can be measured from the pressure difference caused by the fluid flow through the restricted opening.

Can you explain the principle of operation of an orifice plate?

The operating principle of an orifice plate is based on Bernoulli’s theorem. As fluid flows through a pipe and reaches the orifice plate, it is forced to pass through the smaller hole, causing an increase in velocity and a decrease in pressure. The pressure difference before and after the orifice can then be measured and used to calculate the flow rate.

What is an orifice coefficient and why is it important?

The orifice coefficient, often denoted as ‘Cd’, accounts for the effects of real fluids as opposed to ideal ones. It factors in the effects of energy losses, fluid properties, and deviations from theoretical models. This coefficient is important to achieve accurate flow rate measurements.

What materials are typically used in the construction of orifice plates?

Orifice plates are typically made from stainless steel due to their durability and resistance to corrosion. However, they can also be made from other materials such as Monel, Hastelloy, and Tantalum, depending on the nature of the fluid and the requirements of the application.

How is the orifice diameter calculated?

The orifice diameter is calculated based on the flow rate, the properties of the fluid, the pressure difference across the orifice plate, and the diameter of the pipe. There are standard equations available for this calculation, which are outlined in ISO 5167 and ASME standards.

How does temperature affect the performance of an orifice plate?

Temperature affects the density and viscosity of the fluid, which in turn affects the flow rate and pressure drop across the orifice. Consequently, it’s important to consider temperature effects when calculating flow rate.

What is a concentric orifice plate and where is it commonly used?

A concentric orifice plate has a single, centrally located hole. It’s the most common type of orifice plate and is suitable for most clean liquids, gases, and low-velocity steam flows.

Can you explain what an eccentric orifice plate is?

An eccentric orifice plate has an off-center hole. This design is typically used for measuring the flow of fluids with suspended solids, as the offset hole helps to prevent buildup on the plate.

What are some common issues that might occur with an orifice plate?

Common issues include wear and tear, blockage of the orifice, incorrect installation, and inaccurate readings due to changes in fluid properties. Regular maintenance and inspection can help to prevent these issues.

Can you describe the installation process of an orifice plate?

An orifice plate is installed in a pipe in a section called an orifice flange. It’s crucial that the plate is installed with the correct orientation and that it’s positioned correctly in relation to the flow direction. Upstream and downstream pressure taps must also be installed for pressure measurement.

How does an orifice plate differ from a flow nozzle?

While both are types of differential pressure flow meters, they differ in their design and applications. A flow nozzle is designed with a gradually constricting section that reduces wear and is better suited for high-velocity, erosive flows. An orifice plate, however, is simpler and cheaper but may not handle high-velocity, erosive flows as well.

What is a segmental orifice plate and where is it used?

A segmental orifice plate is a type of orifice plate where the orifice is a segment of a circle. It’s typically used for fluids containing solids and slurries to minimize clogging.

What role does Reynolds number play in the operation of an orifice plate?

Reynolds number is a dimensionless number used to predict flow patterns. For an orifice plate, it is critical for determining the type of flow, whether laminar, turbulent, or transitional, which can affect the pressure drop and, subsequently, the accuracy of the flow measurement.

Why is it necessary to measure the upstream and downstream pressure in an orifice plate?

The pressure difference between the upstream and downstream points of an orifice plate is used to calculate the flow rate. This difference arises due to the constriction created by the orifice, causing a drop in pressure as fluid velocity increases.

What is the impact of pipe diameter on the performance of an orifice plate?

The pipe diameter directly affects the calculation of the flow rate. A larger pipe diameter reduces the velocity of fluid for a given flow rate, potentially affecting the differential pressure and thus the accuracy of the flow measurement.

How is the discharge coefficient of an orifice plate determined?

The discharge coefficient is typically determined experimentally. It’s found by comparing the actual flow rate with the theoretical flow rate derived from Bernoulli’s equation. Standards like ISO 5167 provide methods for determining this coefficient.

Can you name a few applications of orifice plates in the industry?

Orifice plates are used across numerous industries for flow measurement. This includes oil and gas production, chemical processing, power generation, water treatment plants, and HVAC systems.

What is meant by ‘beta ratio’ in relation to orifice plates?

The beta ratio (β) is the ratio of the orifice diameter to the inside diameter of the pipe. It’s an important parameter in determining the flow rate as it impacts the velocity and pressure drop across the orifice.

How does an orifice plate handle multi-phase flows?

Handling multi-phase flows with an orifice plate can be challenging due to the variation in fluid properties. It can result in inaccuracies in flow measurement. Specialized orifice designs and calculations, and even other flow meter types, might be needed for accurate measurement in these cases.

What factors should be considered when selecting an orifice plate for a specific application?

Factors include the type and properties of the fluid, flow rate, operating pressure and temperature, pipe size, and the requirements of the measurement (accuracy, range, etc.). It’s also important to consider the conditions that the orifice plate will be subjected to, such as corrosive fluids or high temperatures.

Can you explain the purpose of a quadrant edge orifice plate?

A quadrant edge orifice plate is designed to handle low Reynolds numbers better than a standard orifice plate. The hole has a special edge profile that provides a more consistent pressure drop at lower flow rates, improving accuracy.

What are the advantages and disadvantages of using orifice plates?

Advantages of orifice plates include simplicity, low cost, and no moving parts, which makes them durable and low maintenance. They are also widely applicable for different fluids and flow rates. Disadvantages include potential inaccuracies due to changes in fluid properties, difficulty with multi-phase flows, and susceptibility to wear and tear or blockages.

What is the role of a pressure tap in an orifice plate setup?

A pressure tap is used to measure the fluid pressure at specified locations upstream and downstream of the orifice plate. The pressure difference between these two points is used to calculate the flow rate.

What types of pressure taps are used with orifice plates?

There are several types of pressure taps, including flange taps, D and D/2 taps, corner taps, and pipe taps. The choice of tap type depends on the application and required accuracy.

How does the installation orientation of an orifice plate affect its operation?

Installation orientation can greatly affect the performance of an orifice plate. In horizontal pipelines, the plate should be installed with the orifice at the bottom for liquid flows and at the top for gas flows to avoid the accumulation of sediments or trapped gases respectively. In vertical pipelines, the orientation will depend on whether the flow direction is upwards or downwards.

Why are orifice plates often used in conjunction with flow computers?

Flow computers can process the differential pressure measurement from the orifice plate and, considering other variables such as temperature and pressure, can compute the flow rate in real-time. They provide more accurate and reliable results compared to manual calculations.

How are orifice plates maintained and inspected?

Maintenance and inspection may include checking for damage, wear, and tear, or blockage in the orifice. The orifice edges should be sharp and free from nicks and burrs. The pressure taps should also be inspected for blockage. Regular calibration of the pressure transmitters is also necessary for accurate measurements.

Can orifice plates be used for both compressible and incompressible flows?

Yes, orifice plates can be used for both compressible (like gases) and incompressible (like liquids) flows. However, the calculations for flow rate will differ based on the fluid type.

How does an orifice plate handle viscous flows?

In viscous flows, energy losses due to friction become significant. These can result in a lower pressure drop and less accurate flow measurements. Special considerations or corrections may need to be applied when dealing with viscous flows.

What kind of pressure loss should be expected with an orifice plate?

The pressure loss in an orifice plate is permanent and is dependent on the beta ratio, the fluid properties, and the flow rate. The higher the beta ratio, the higher the pressure loss. However, this loss is often considered acceptable in the overall system design.

Can you describe the difference between full-bore and reduced-bore orifice plates?

A full-bore orifice plate has a hole size that is similar to the pipe diameter, while a reduced-bore orifice plate has a smaller hole size. Reduced-bore plates create a greater pressure drop and can measure lower flow rates than full-bore plates.

Can an orifice plate measure flow in both directions?

Generally, orifice plates are designed to measure flow in one direction only. If bidirectional flow measurement is needed, a special type of orifice plate known as a bidirectional orifice plate may be used.

What is a restriction orifice plate and what is its application?

A restriction orifice plate is similar to a standard orifice plate, but its primary purpose is to reduce fluid pressure or limit flow rate, rather than to measure flow. It’s often used in systems where a specific pressure drop is required.

How does a change in fluid density affect the function of an orifice plate?

Fluid density is a key parameter in the calculation of flow rate through an orifice plate. Changes in fluid density, such as due to temperature or pressure variations, can therefore affect the accuracy of flow measurements.

What is the relationship between the beta ratio and the accuracy of an orifice plate?

The beta ratio can greatly affect the accuracy of an orifice plate. A lower beta ratio (small orifice) results in a higher pressure drop and potentially more accurate measurement, but with greater energy loss. Conversely, a higher beta ratio (large orifice) results in a lower pressure drop and less energy loss, but potentially less accurate measurement.

What are the effects of vibration on the performance of an orifice plate?

Vibration can affect the accuracy of an orifice plate measurement. It may cause fluctuation in the pressure readings and can also cause physical damage to the orifice plate and other elements of the flow measurement system over time.

What happens if the fluid flow exceeds the capacity of the orifice plate?

If the fluid flow exceeds the capacity of the orifice plate, it may result in ‘choked flow’, where the flow rate no longer increases with increasing pressure difference. This can lead to inaccurate readings and potential damage to the orifice plate and piping system.

What is the impact of pipe roughness on the performance of an orifice plate?

Pipe roughness can influence the velocity profile of the fluid and the boundary layer conditions at the pipe wall, potentially affecting the pressure drop across the orifice plate and thus the accuracy of the flow measurement.

Can orifice plates handle pulsating flow?

Pulsating flow can cause fluctuations in the differential pressure, which can affect the accuracy of the flow measurement. While an orifice plate can technically handle the pulsating flow, additional measures, like damping, might be required to ensure accurate readings.

How does a change in the velocity profile of the fluid affect an orifice plate measurement?

Changes in the velocity profile can affect the pressure drop across the orifice plate, and thus the calculated flow rate. A fully developed, symmetrical velocity profile is desirable for accurate measurements.

Can orifice plates handle slurries or fluids with solids?

While orifice plates can handle slurries or fluids with solids, these can cause wear and tear or blockages. Special orifice designs, like eccentric or segmental plates, might be more suitable in these cases to prevent buildup and maintain accuracy.

What are the environmental considerations when using orifice plates?

Orifice plates should be selected and designed considering the operating environment. This includes factors like corrosive or erosive conditions, high temperatures, and potentially explosive atmospheres.

What is the role of flow conditioners in an orifice plate system?

Flow conditioners are used to ensure a fully developed, symmetrical velocity profile at the orifice plate, which is essential for accurate flow measurement. They can help to mitigate the effects of pipe bends, valves, or other disturbances upstream of the orifice.

Why is it important to consider the straight run requirements for an orifice plate?

Straight-run requirements ensure a fully developed and stable velocity profile for accurate flow measurement. Insufficient straight runs may cause flow disturbances and inaccurate readings.

How are differential pressure transmitters used with orifice plates?

Differential pressure transmitters are used to measure the pressure difference across the orifice plate, which is directly related to the fluid flow rate. These transmitters convert the pressure differential into an electrical signal that can be processed to calculate the flow rate.

Can an orifice plate be used to measure the flow rate of steam?

Yes, orifice plates can be used to measure the flow rate of steam. However, special considerations might need to be applied due to the compressibility and phase change possibilities of steam.

How does cavitation affect the performance of an orifice plate?

Cavitation can occur if the fluid pressure drops below its vapor pressure, causing vapor bubbles to form and then collapse. This can cause significant damage to the orifice plate and other equipment and can affect the accuracy of flow measurements.

What is an integral orifice plate?

An integral orifice plate is a type of orifice plate that is designed for use in small line sizes and low flow rates. It’s typically part of a complete meter run assembly and is often used when the line size is less than 2 inches in diameter.

Why do orifice plates sometimes have beveled edges?

Beveled edges on orifice plates are used to reduce the effects of wear and tear, particularly in flows with abrasive particles. The bevel also helps to establish a more stable flow through the orifice, aiding in accurate measurement.

What safety considerations are needed when installing or servicing orifice plates?

When installing or servicing orifice plates, safety precautions like isolating the pipeline, relieving pressure, and wearing appropriate PPE should be followed. It’s also important to ensure that the system is free from hazardous fluids during maintenance.

How do pressure losses across an orifice plate affect the efficiency of a fluid system?

Pressure losses across an orifice plate represent a loss of energy in the fluid system, which can reduce overall system efficiency. However, these losses are often accepted for the benefit of accurate flow measurement.

Can an orifice plate be used in a high-pressure system?

Yes, orifice plates can be used in high-pressure systems. However, it’s important to ensure that the plate and associated equipment are designed to withstand the operating pressure and that safety considerations are adhered to.

What is the significance of the orifice plate thickness?

The thickness of the orifice plate affects the discharge coefficient and the pressure drops across the plate. A thicker plate might also provide better resistance to wear and damage, particularly in high-velocity or abrasive flows.

Can orifice plates measure bi-directional flow?

Traditional orifice plates are designed to measure flow in one direction. For bi-directional flow measurement, a bi-directional orifice plate, which has a symmetrical design, can be used.

How is flow measurement using an orifice plate affected by pressure and temperature changes?

Pressure and temperature changes can affect the density and viscosity of the fluid, which in turn can affect the velocity and pressure drop across the orifice, and thus the calculated flow rate. Corrections may need to be applied for accurate measurements under varying conditions.

What are the limitations of using orifice plates for flow measurement?

Limitations include potential inaccuracies due to changes in fluid properties or flow conditions, difficulty with multi-phase or pulsating flows, susceptibility to wear and blockage, and energy losses due to the pressure drop.

Can orifice plates be used to measure gas flow?

Yes, orifice plates can be used to measure gas flow. However, since gases are compressible, changes in pressure and temperature can significantly affect the density and thus the flow measurement. Appropriate corrections must be applied.

What type of signal is typically produced by a differential pressure transmitter in an orifice plate setup?

The typical signal produced by a differential pressure transmitter is a 4-20 mA current signal, which is proportional to the measured pressure difference across the orifice.

How is the orifice diameter determined for an orifice plate?

The orifice diameter is determined based on the desired flow range, the pipe diameter, the fluid properties, and the operating pressure and temperature. Standards like ISO 5167 provide methods for calculating the orifice diameter.

How does the position of the pressure taps affect the performance of an orifice plate?

The position of the pressure taps determines where the upstream and downstream pressures are measured. Incorrect positioning can result in inaccurate pressure readings and thus inaccurate flow measurements. Standard locations are defined by standards like ISO 5167.

What is the role of the ‘approach’ and ‘exit’ lengths in an orifice plate system?

The ‘approach’ length is the straight length of the pipe upstream of the orifice plate, while the ‘exit’ length is the straight length downstream. These lengths are important for establishing a fully developed flow profile for accurate measurement.

How does an orifice plate measurement change if the flow becomes supersonic?

If the flow becomes supersonic, the relationship between pressure drop and flow rate changes, potentially leading to inaccurate measurements. Also, the high velocities can cause physical damage to the orifice plate and other components.

How do changes in fluid viscosity affect an orifice plate measurement?

Changes in fluid viscosity can affect the velocity profile and the pressure drop across the orifice, and thus the calculated flow rate. Viscosity corrections may need to be applied in the flow rate calculation for accurate measurement.

How can the performance of an orifice plate be checked or validated?

The performance of an orifice plate can be checked by calibrating the differential pressure transmitter, inspecting the orifice plate for wear or damage, and comparing the measured flow rate with other flow measurements or expected values.

Can orifice plates be used to measure the flow rate of non-Newtonian fluids?

Yes, but it can be complex due to the varying viscosity of non-Newtonian fluids. Specialized calculations or flow meter types may be required for accurate measurement.

How is the material for an orifice plate selected?

The material for an orifice plate should be chosen based on the type of fluid, the operating conditions (pressure, temperature), and environmental factors (corrosion, erosion). Common materials include stainless steel, Monel, and Hastelloy.

What happens if the differential pressure transmitter in an orifice plate system fails?

If the differential pressure transmitter fails, it will no longer accurately measure the pressure difference across the orifice plate, resulting in inaccurate flow measurements. It should be repaired or replaced as soon as possible to restore accurate flow measurement.

What is a quadrant-edge orifice plate?

A quadrant-edge orifice plate is a type of orifice plate designed for low Reynolds number flows and viscous fluids. The edge of the orifice is a quarter circle, which helps to maintain a more constant discharge coefficient over a wider range of Reynolds numbers.

How can the beta ratio of an orifice plate be changed?

The beta ratio can be changed by changing the diameter of the orifice in relation to the pipe diameter. This can be done by replacing the orifice plate with one that has a different orifice diameter.

How does a segmental orifice plate differ from a standard orifice plate?

A segmental orifice plate has a segmental or partial hole, rather than a full hole. It’s often used in flows with solids or slurry to prevent buildup at the bottom of the pipe.

What is an eccentric orifice plate and where is it used?

An eccentric orifice plate has the hole placed off-center, or eccentrically. This design is often used in horizontal pipes carrying dirty or slurry fluids, which helps to prevent buildup at the bottom of the pipe.

Can orifice plates be used in a variable flow system?

Yes, orifice plates can be used in variable flow systems. However, changes in flow conditions can affect the pressure drop and the accuracy of the flow measurement.

What are some alternatives to orifice plates for flow measurement?

Alternatives to orifice plates include venturi tubes, flow nozzles, pitot tubes, turbine meters, ultrasonic flow meters, and magnetic flow meters. The choice depends on the specific application and requirements.

How does an orifice plate compare to a flow nozzle in terms of performance and application?

Compared to a flow nozzle, an orifice plate is simpler and cheaper, but typically less accurate and more prone to wear and tear. Flow nozzles are often used in high-velocity, erosive flows where an orifice plate would wear out quickly.

Can an orifice plate measure flow rate at very low pressures?

Yes, an orifice plate can measure flow rate at very low pressures. However, the differential pressure across the plate may be small and difficult to measure accurately, so a sensitive differential pressure transmitter may be needed.

What is a conditioning orifice plate?

A conditioning orifice plate is a type of orifice plate with multiple holes, designed to condition the flow and reduce the need for straight run lengths. It’s often used in situations where space constraints limit the available straight run upstream of the plate.

How does erosion affect an orifice plate?

Erosion can cause wear and tear on the orifice plate, particularly on the edges of the orifice. This can alter the orifice diameter and shape, affecting the pressure drop and the accuracy of flow measurements.

Can orifice plates be used in high-temperature applications?

Yes, orifice plates can be used in high-temperature applications, provided that they and the associated equipment are made of materials that can withstand the operating temperature. Special care must also be taken to ensure that the fluid properties under these conditions are correctly accounted for in the flow rate calculation.

What is the effect of pipe diameter on orifice plate measurement?

The pipe diameter affects the beta ratio and the flow rate that can be measured by an orifice plate. A change in pipe diameter would require a change in the orifice diameter to maintain the same beta ratio and measurement accuracy.

How do changes in fluid composition affect orifice plate measurements?

Changes in fluid composition can affect the density and viscosity of the fluid, which can affect the velocity and pressure drop across the orifice plate, and thus the calculated flow rate. Corrections may need to be applied for accurate measurements under varying conditions.

How are differential pressure readings from an orifice plate typically transmitted for processing and display?

Differential pressure readings are typically converted into an electrical signal (like 4-20 mA) by the differential pressure transmitter. This signal is then transmitted to a control room or other location, where it can be processed to calculate the flow rate and displayed for monitoring.

What is the importance of the discharge coefficient in orifice plate calculations?

The discharge coefficient accounts for the effects of fluid velocity, viscosity, and other factors on the actual flow through the orifice. It’s used to correct the theoretical flow rate calculation based on the ideal orifice equation, to give a more accurate real-world flow rate.

Can an orifice plate be used in vertical pipes?

Yes, an orifice plate can be used in vertical pipes. However, the orientation of the flow (upwards or downwards) and the potential for stratified or uneven flow profiles due to gravity may need to be considered in the flow rate calculation.

Can orifice plates be used for cryogenic fluids?

Yes, orifice plates can be used for cryogenic fluids. However, special consideration must be given to the material selection to withstand the low temperatures, and to the calculation of fluid properties under these conditions for accurate flow measurement.

What is the effect of the orifice plate edge shape on the flow measurement?

The shape of the orifice edge can affect the formation of the vena contracta and the pressure recovery downstream of the orifice, which can in turn affect the pressure drop and the accuracy of the flow measurement. The edge is often sharp for the most accurate results.

What are the requirements for orifice plate installation?

Orifice plates should be installed with the orifice edge perpendicular to the flow, and with sufficient straight run lengths upstream and downstream to ensure a fully developed flow profile. The pressure taps should also be correctly positioned. The plate should be properly centered and sealed in the pipe to avoid bypass flow.

How does the placement of the orifice plate affect the measurement?

The placement of the orifice plate in the pipe is crucial for accurate measurement. The plate needs to be centrally located and properly aligned with the flow direction. Improper placement can result in asymmetrical flow or partial blockage, leading to inaccuracies in the measurement.

Why is the upstream face of the orifice plate usually flat?

The upstream face of the orifice plate is usually flat to minimize disturbances to the flow entering the orifice. Any irregularities on the upstream face could cause turbulence or an uneven velocity profile, which could affect the pressure drop and the accuracy of the flow measurement.

What is the importance of the Reynolds number in orifice plate measurements?

The Reynolds number is a measure of the flow regime (laminar, transitional, or turbulent). It affects the discharge coefficient and the accuracy of the flow measurement. The orifice plate is typically designed for turbulent flow, where the discharge coefficient is relatively constant.

Can an orifice plate measure the flow rate in a multi-phase flow system?

Orifice plates can be used in multi-phase flow systems, but they can be complex due to the varying properties and flow behavior of the different phases. Specialized calculations or flow meter types may be required for accurate measurement.

What is a conical entrance orifice plate?

A conical entrance orifice plate is a type of orifice plate with a conical depression on the upstream side, leading into the orifice. This design can help to reduce the pressure loss and increase the pressure recovery downstream of the orifice.

How does the orifice plate cause a pressure drop in the fluid flow?

The orifice plate causes a pressure drop by constricting the flow, which increases the velocity and decreases the pressure at the orifice according to Bernoulli’s principle. The pressure downstream of the orifice is lower than the pressure upstream.

Can orifice plates be used in corrosive fluids?

Yes, orifice plates can be used in corrosive fluids, provided that they are made of a material that is resistant to a specific type of corrosion. Special coatings or liners may also be used to protect the plate.

What maintenance is required for an orifice plate?

Maintenance for an orifice plate includes regular inspection for wear, erosion, or buildup, calibration of the differential pressure transmitter, and replacement of the orifice plate if necessary. The specific requirements can depend on the service conditions and the type of fluid.

How is the beta ratio of an orifice plate defined?

The beta ratio of an orifice plate is defined as the ratio of the diameter of the orifice to the diameter of the pipe. It is a key factor in the design of the orifice plate and the calculation of the flow rate.

What factors affect the accuracy of an orifice plate flow measurement?

Factors that affect the accuracy of an orifice plate flow measurement include the precision of the orifice diameter and plate thickness, the positioning of the pressure taps, the calibration of the differential pressure transmitter, the stability and profile of the flow, and the properties of the fluid.

What types of fluids can be measured with an orifice plate?

Orifice plates can be used to measure a wide range of fluids, including liquids, gases, and steam. They can also be used with clean, dirty, or slurry fluids, although special designs may be needed for some types of fluids.

What is the equation to calculate the flow rate through an orifice plate?

The equation to calculate the flow rate (Q) through an orifice plate is given by the formula:

Q = Cd * A * √(2 * ΔP / ρ)

Where:

Q = Flow rate (in volumetric units per unit time)

Cd = Discharge coefficient

A = Cross-sectional area of the orifice

ΔP = Pressure drop across the orifice

ρ = Density of the fluid

How is the discharge coefficient (Cd) determined for an orifice plate?

The discharge coefficient (Cd) for an orifice plate is determined experimentally for each specific orifice design and flow condition. It represents the efficiency of the orifice plate in converting the pressure differential into flow rate. Cd values can be obtained from standards, such as ISO 5167, or through calibration tests conducted in a controlled laboratory setting.

What is the formula for the cross-sectional area (A) of an orifice plate?

The formula for the cross-sectional area (A) of an orifice plate is given by:

A = (π * d^2) / 4

Where:

A = Cross-sectional area of the orifice

d = Diameter of the orifice

How is the pressure drop (ΔP) across an orifice plate measured?

The pressure drop (ΔP) across an orifice plate can be measured using pressure sensors placed upstream and downstream of the orifice. The pressure difference between these two points indicates the pressure drop. Alternatively, a differential pressure transmitter can be used to directly measure the pressure difference and provide an output signal proportional to ΔP.

What is the formula to calculate the velocity (V) of the fluid through an orifice plate?

The formula to calculate the velocity (V) of the fluid through an orifice plate is given by the equation:

V = √(2 * ΔP / ρ)

Where:

V = Velocity of the fluid

ΔP = Pressure drop across the orifice

ρ = Density of the fluid

How does the density of the fluid affect the flow rate through an orifice plate?

The density of the fluid (ρ) directly affects the flow rate through an orifice plate. As the density increases, the flow rate decreases for a given pressure drop. This is because a denser fluid requires more energy to flow through the orifice, resulting in a lower flow rate. Conversely, a less dense fluid will have a higher flow rate for the same pressure drop.

What are the typical units of measurement used in orifice plate equations?

The typical units of measurement used in orifice plate equations are as follows:

Flow rate (Q): Cubic meters per second (m³/s), liters per second (L/s), or other volumetric units per unit time.

Discharge coefficient (Cd): Unitless.

Cross-sectional area (A): Square meters (m²).

Pressure drop (ΔP): Pascals (Pa), bar, or other pressure units.

Density (ρ): Kilograms per cubic meter (kg/m³), grams per cubic centimeter (g/cm³), or other density units.

Velocity (V): Meters per second (m/s) or other linear velocity units.

Read Next: