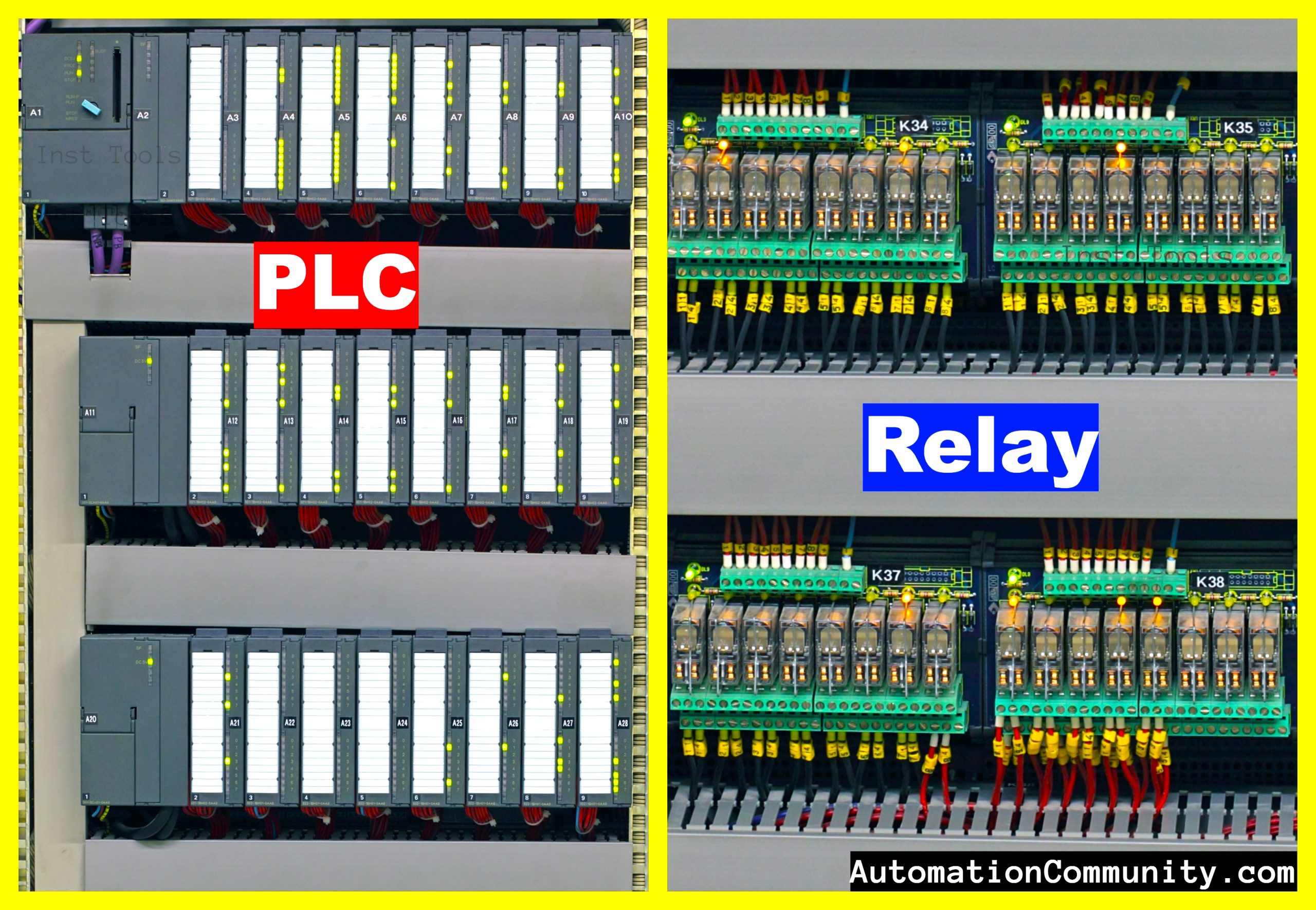

Difference Between PLC and Relay

In this article, you will learn the basic difference between PLC and Relay in electrical and instrumentation systems.

PLC

A programmable logic controller (PLC) is designed to replace traditional mechanical relays and timers in a variety of applications. PLC is programmed to perform a wide range of tasks, such as controlling motors, monitoring sensors, and communicating with other devices.

PLC is programmed to control the operation of relays, allowing for precise control over industrial processes. Relays can also be used as input devices for PLCs, allowing PLCs to sense the state of equipment and respond accordingly.

Relay

A relay is an electrically operated switch that can be used to control the flow of electricity in a circuit. A relay typically consists of a coil of wire and one or more sets of contacts. When the coil is energized, it creates a magnetic field that causes the contacts to close or open, which in turn controls the flow of electricity.

Relays are commonly used in PLCs to control the flow of electricity to various devices, such as motors and lights. They can also be used as input devices to provide signals to the PLC, such as when a button is pressed or a sensor is triggered.

Relays are still being used in many applications such as HVAC, Motor control, home automation, Industrial Control, Automotive, etc. Relay is a simple, robust, and cost-effective solution to control and switch high voltage and current.

Key Differences

There are several key differences between PLCs and relays:

- Complexity: PLCs are more complex than relays, and they are capable of performing a wider range of tasks. Relays are simple devices that are designed to perform a specific task, while PLCs are digital computers that can be programmed to perform a wide range of tasks.

- Programming: PLCs are programmed using industrial programming languages, while relays do not require programming.

- Functionality: PLCs can be used to control and monitor a wide range of processes and systems, while relays are typically used to control a specific aspect of a process or system.

- Cost: PLCs are generally more expensive than relays, especially for smaller-scale applications. However, relays may be more cost-effective for simple tasks or systems.

- Reliability: PLCs are generally more reliable than relays, as they are less prone to failure due to their complex design and the use of high-quality components.

Difference Between PLC and Relay

The below table shows the differences between PLC and Relays based on features.

| Feature | PLC | Relay |

|---|---|---|

| Programming Language | Ladder logic, Function Block Diagram, etc | Contact and Coil Logic |

| Input/Output Capability | High | Low |

| Complexity of control logic | High | Low |

| Speed of execution | Fast | Slow |

| Cost | High | Low |

| Flexibility | High | Low |

| Error Detection and Correction | High | Low |

| Monitoring and diagnosis capability | High | Low |

Conclusion

PLCs are programmable controllers that are used for industrial automation and control, while relays are electrically operated switches that are commonly used in PLCs to control the flow of electricity to various devices.

Read Next: