What is a NAMUR Sensor? – Advantages and Disadvantages

NAMUR sensor is a proximity sensor developed to be used in industrial hazardous areas, where the risk of explosive gases or combustible dust is present or formed in the facility.

In this article, we will take about the NAMUR sensors, how they work, and the advantages & disadvantages of using NAMUR sensors.

What is a Proximity Sensor?

A proximity sensor is a non-contact type sensor that detects the presence of an object. Proximity sensors can be implemented using various techniques such as optical, ultrasonic, and Hall effects.

The proximity sensor acts as an ON/OFF switch. It can be a NO or an NC.

The two most commonly used proximity sensors are the inductive proximity sensor and the capacitive proximity sensor.

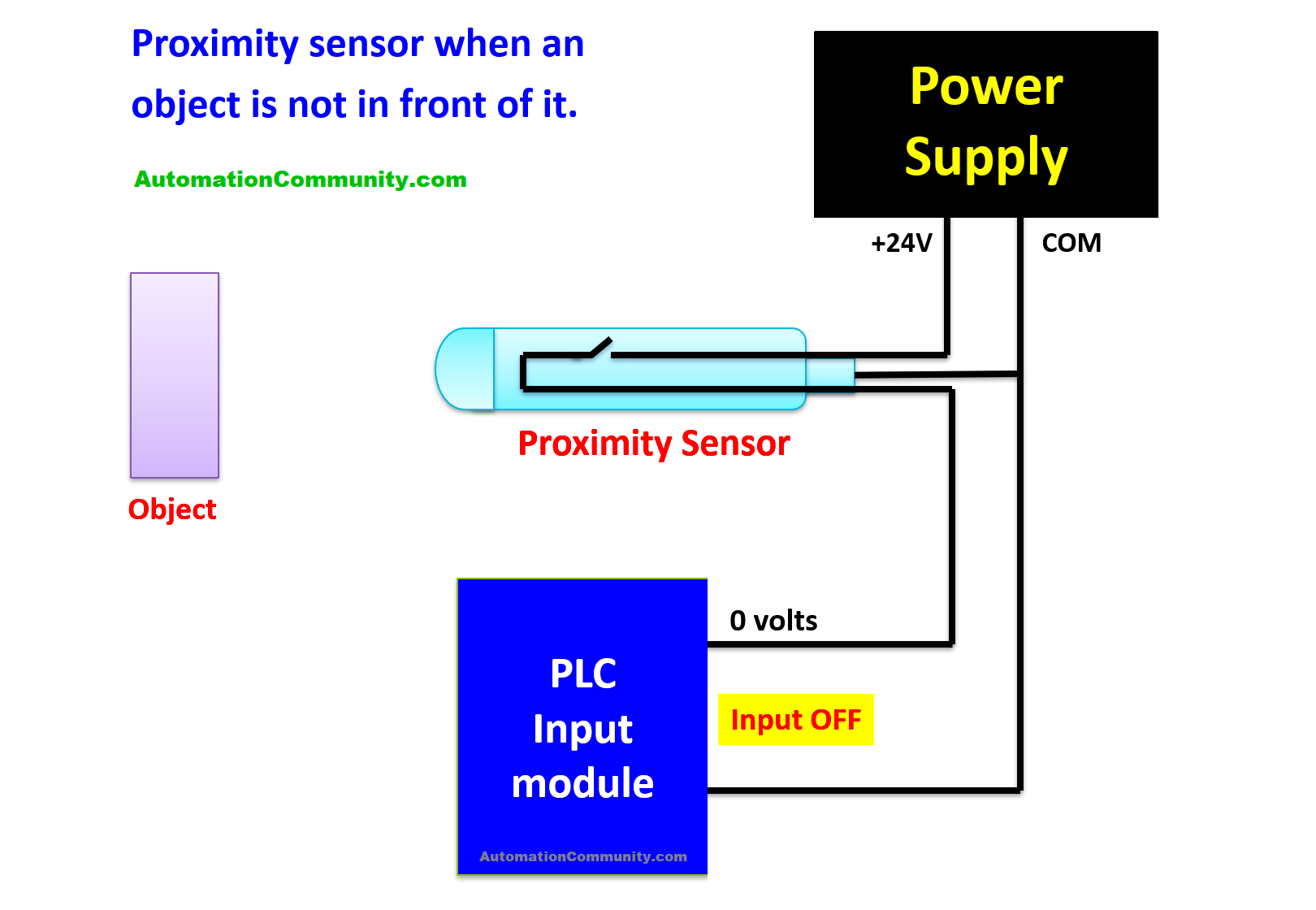

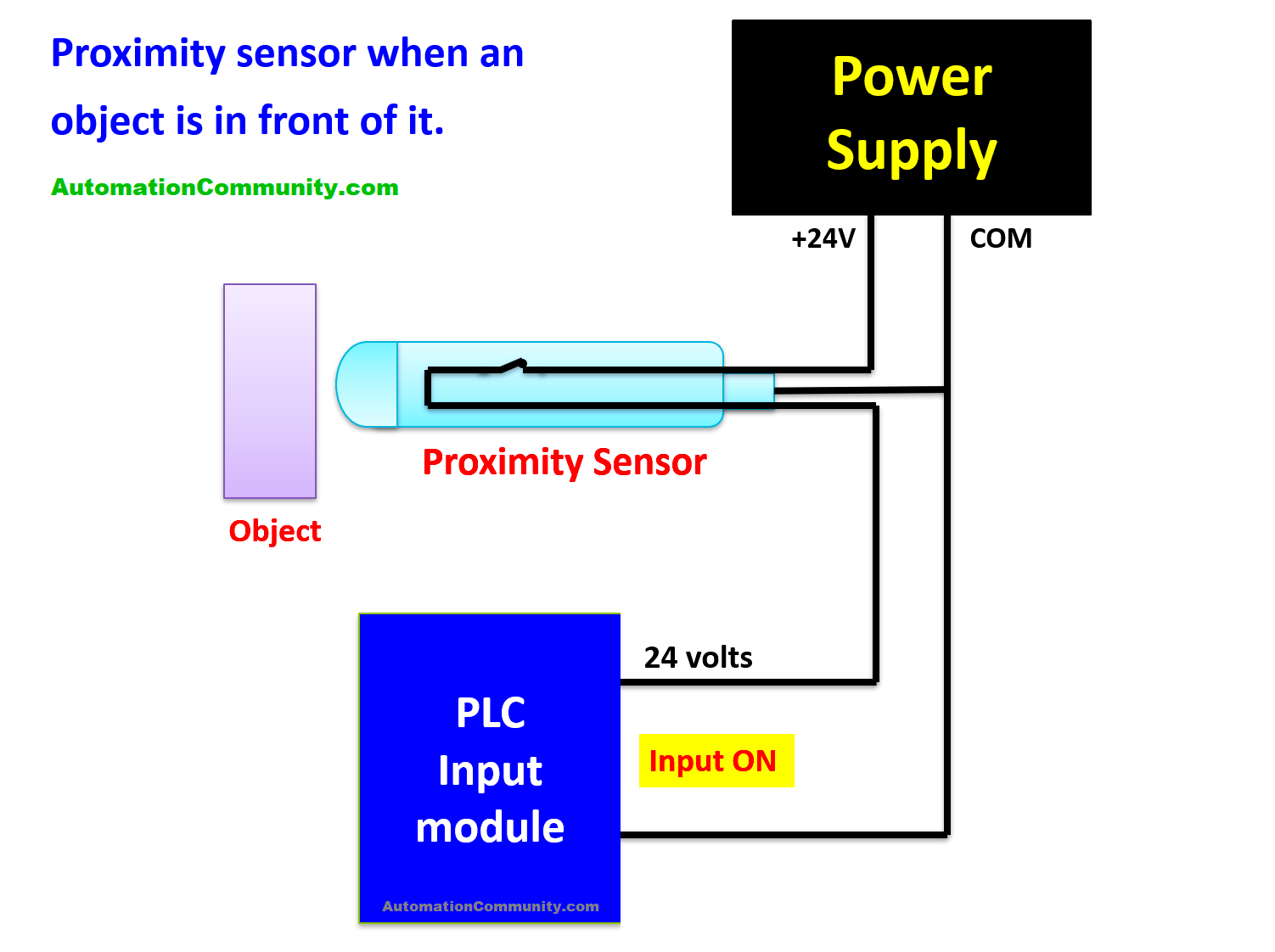

A proximity sensor will either give or prevent a 24-volt signal to an input module like a PLC. see pictures 1 & 2 depicting proximity sensor behavior when an object is present or not.

Why can’t we use normal Proximity Sensors in Hazardous Areas?

Standard three-wire proximity sensors use two wires for power and the third for the output, they have either a PNP or an NPN transistor output that switches the sensor if it detects a target.

The transistor output works as a mechanical switch powered by a 24 VDC power supply using two wires, the third wire carries the signal status of the sensor and is usually connected to a DI card of a PLC.

If you need to install a proximity sensor in a hazardous area that contains a potentially explosive atmosphere, you cannot use a standard three-wire sensor, because when the sensor switches to indicate a detection, the signal wire is connected or disconnected to the power supply, that action can generate an arc which can be a potential source of ignition.

The switching manner of the proximity sensor can cause a spark that can be very dangerous if the sensor is installed in a hazardous area.

And that is where a NAMUR sensor comes in use.

What is a NAMUR sensor?

A NAMUR sensor is a 2 wire proximity sensor that was developed to ensure safety in hazardous areas.

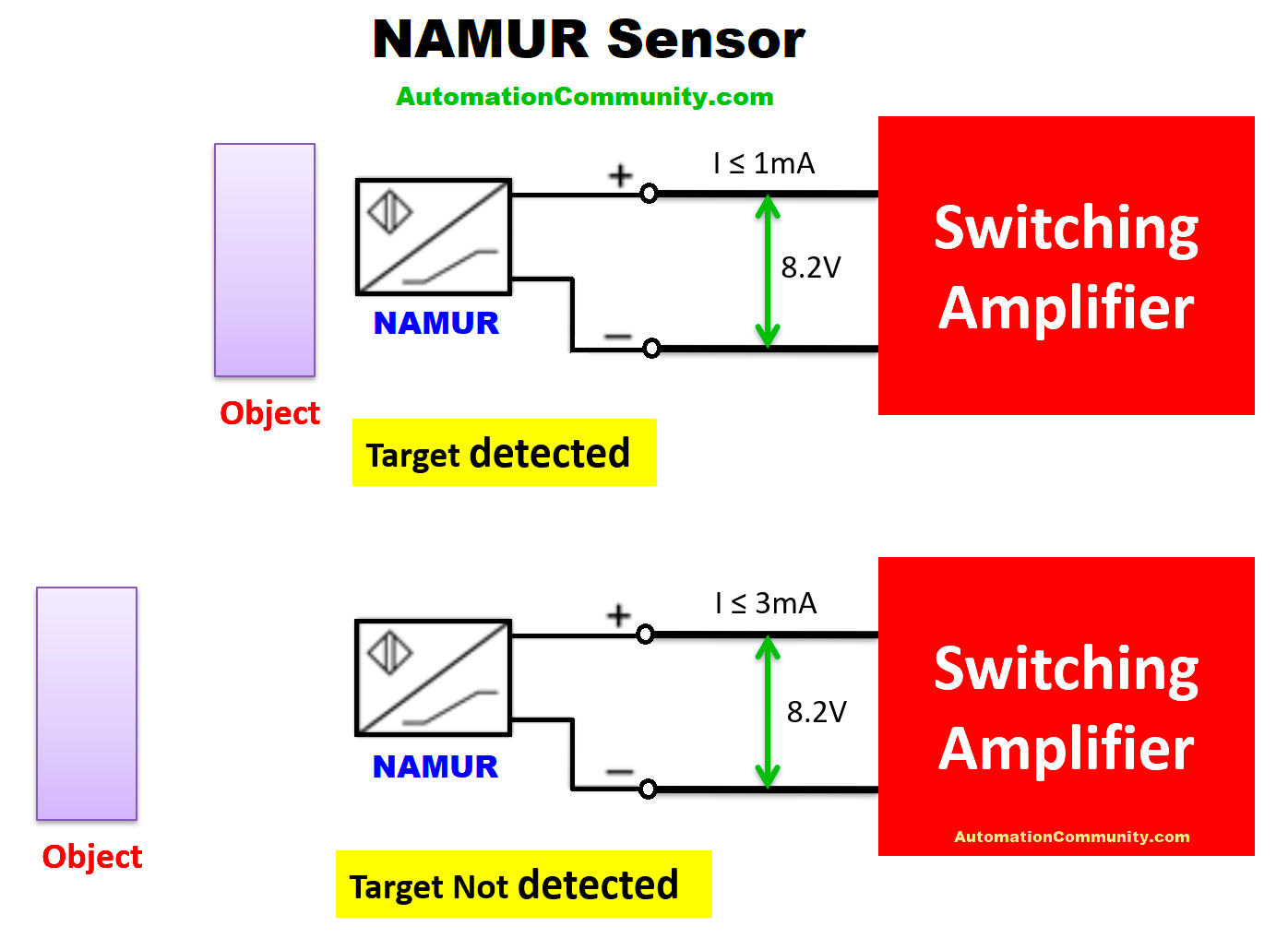

NAMUR sensors are designed to be powered by a switching amplifier that limits the available voltage to 8.2 V. This voltage is kept constant by using two different current levels to indicate if the sensor is detecting a target or not. These current levels are usually 1 mA with a target present and 3 mA without one.

So instead of a switching manner as in normal PNP or NPN proximity which can be very dangerous in hazardous areas, you now have a 1 mA or a 3 mA to indicate the presence or not of an object. These values are very small to be able to ignite an explosion or a fire in a hazardous area. And that is why a NAMUR sensor is considered intrinsically safe.

Why use a NAMUR Sensor?

NAMUR sensors do not switch a transistor output, they modify their impedance when they detect a target. Then their impedance goes from 1kΩ to 10 kΩ in a detection event. So, there is never a switching event, and no arcs are possible.

Since most PLC’s DI cards cannot detect such low variations of current effectively, a switching amplifier is employed to transform the current level status of the NAMUR sensor into a signal that the PLC’s I/O card can detect.

The most frequently used switching amplifiers have a relay output, adequate for applications with a low switching frequency, or a transistor output that is more adequate for higher switching frequencies.

Advantages of NAMUR Sensors

- NAMUR sensors offer the possibility of sensor diagnostics. They work like monitored dry contacts. If the wire is broken, there will be either no current or less than 0.15 mA on the cable, and since the switching amplifier is expecting to get either 1 or 3 mA, then a wire breakage event can be detected. If the current goes above 6.5 mA, then there is a shortage in the wiring.

- NAMUR sensors also can support higher switching frequencies than three-wire sensors.

- And although they are designed to operate with 8.2 V, their working voltage range usually goes from 5 to 24 V.

Disadvantages of NAMUR Sensors

- A NAMUR sensor is intrinsically safe only if the used amplifier is also an intrinsically safe device.

- The need for an amplifier circuit as external hardware will increase the cost of the NAMUR sensor.

NAMUR Sensors in Hazardous Areas

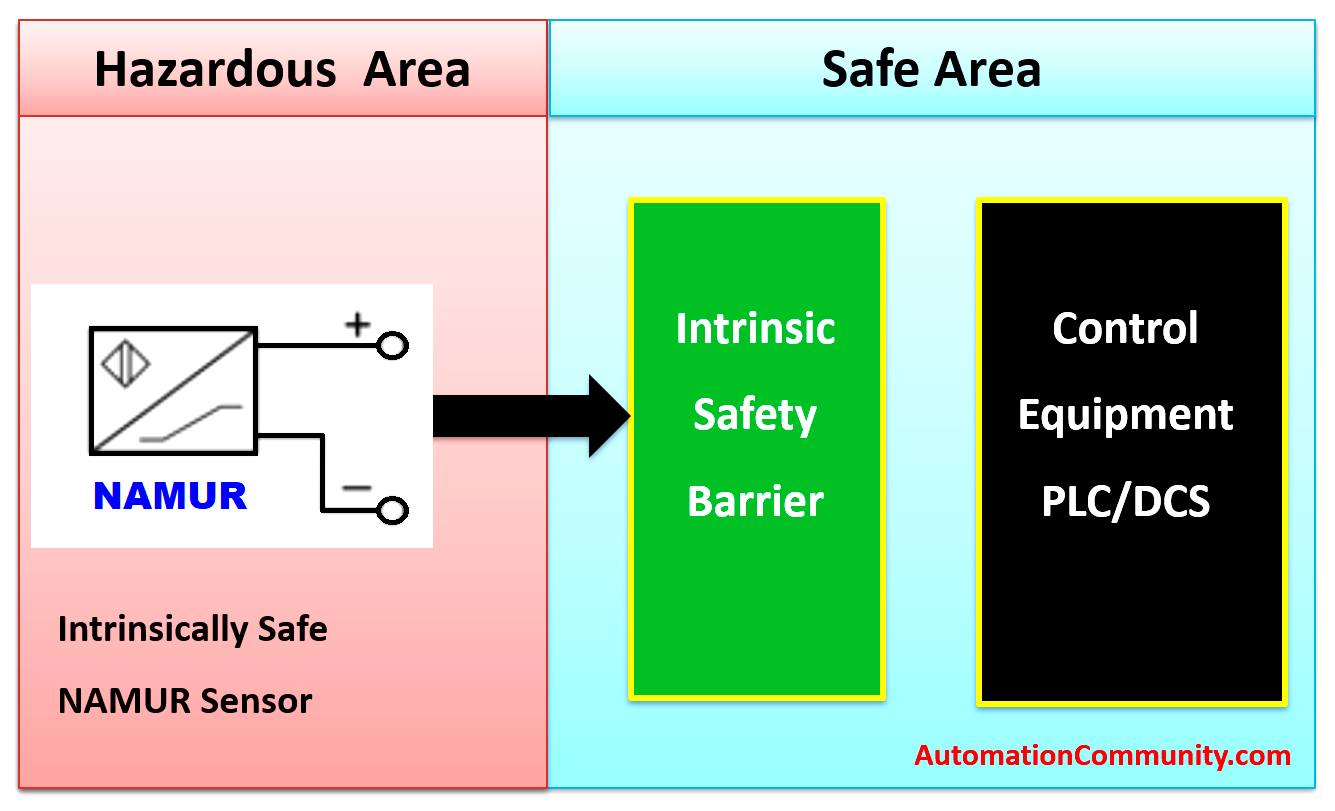

In explosion-protection applications, the operating location of the intrinsically safe NAMUR sensor is located in the explosion-hazardous area.

The isolated switch amplifier must be installed outside the explosion-hazardous area. See picture 5.

NAMUR sensors are designed to be intrinsically safe (IS). But they are only safe only if the switching amplifier used is also (IS). In order to provide these requirements an IS interface should be used to connect the sensor to the control system.

Intrinsic Barrier

The intrinsic Barrier usually uses the following components.

- Using a Zener barrier, which will require an intermediate relay a low-impedance earth connection.

- Using an IS galvánic isolator, which offers galvánic isolation, either relay or electronics outputs, and wiring diagnostics.

Conclusion

- NAMUR sensor is used to ensure safety in hazardous areas.

- NAMUR sensors have to be used with a switching amplifier circuit because PLC can’t handle signals with such low currents.

- The switching amplifier must also be an intrinsic device.

- NAMUR sensors can provide diagnostic functions; they can detect a wire break or short circuit in the wiring.

Read Next:

Comments

6

very informative.

Excellent information.

Hi Mahmoud – nice presentation, please note the following:

Equipment certified as intrinsically safe Exi is designed so it’s circuits (irrespective of their components) do not store enough energy to create a spark that could ignite the vapours / gasses / dust in the zone – thus if the cable is damaged for example, the energy from the device will not cause an ignition. The circuits can contain transistors / dry contacts etc etc be analogue or switching could cause small sparks if damaged but would not hold enough energy to cause ignition.

A barrier must be used in the safe area to limit the power transmitted by the power supply to the field circuits, to below a level that might create a spark that could ignite the vapours / gasses / dust in the zone – thus if the cable is damaged and creates a spark, the barrier will limit the energy from the power supply to prevent ignition.

Well said and agreed on the principle of intrinsic safety.

Excellent, thx

The description of the NAMUR switching amp is wrong. The open loop voltage of nominally 8.2 V is NOT! kept constant at all. There must be a series resistor of 1 kOhm in series with the voltage source, thus the short ckt current is 8.2 mA. E.G when current is 3 mA, 3 V will drop across this internal resistor, and only 5.2 V will be present at the terminals oh the amplifier.