Thermocouple Questions and Answers

The thermocouples principle is based on three fundamental thermoelectric effects: the Seebeck effect, the Peltier effect, and the Thomson effect.

Thermocouples operate on the Seebeck effect, discovered by Thomas Johann Seebeck in 1821. The Seebeck effect states that when two different types of metals or semiconductors (referred to as legs) are joined together at two junctions and one junction (the measuring junction) is at a different temperature from the other (the reference junction), a voltage is produced. This voltage, known as the thermoelectric electromotive force (emf), can be measured. The magnitude of this emf is directly related to the difference in temperature between the two junctions.

The Peltier effect complements the Seebeck effect by explaining that heat will be absorbed or released at the junction of two different materials when an electric current is passed through them.

The Thomson effect states that heat is absorbed or emitted along the length of a conductor when there is both a temperature gradient and an electric current present in the conductor.

In the application of a thermocouple, it’s the Seebeck effect that’s primarily utilized. The emf produced due to the temperature difference between the measuring junction (exposed to the process we want to monitor or control) and the reference junction (kept at a known, typically stable temperature) is measured and converted into a temperature reading.

It’s important to note that thermocouple readings are not absolute; they only measure the difference in temperature between the two junctions. If the reference junction’s temperature is known and maintained, the absolute temperature at the measuring junction can be determined.

Thermocouple Questions and Answers

Thermocouples are widely used in a variety of industrial and scientific applications due to their durability, wide temperature ranges, quick response time, and cost-effectiveness. They come in several types, each with a different combination of metals and suitable for a different temperature range. These types, such as Type K (chromel-alumel) or Type J (iron-constantan), are standardized and color-coded for easy identification.

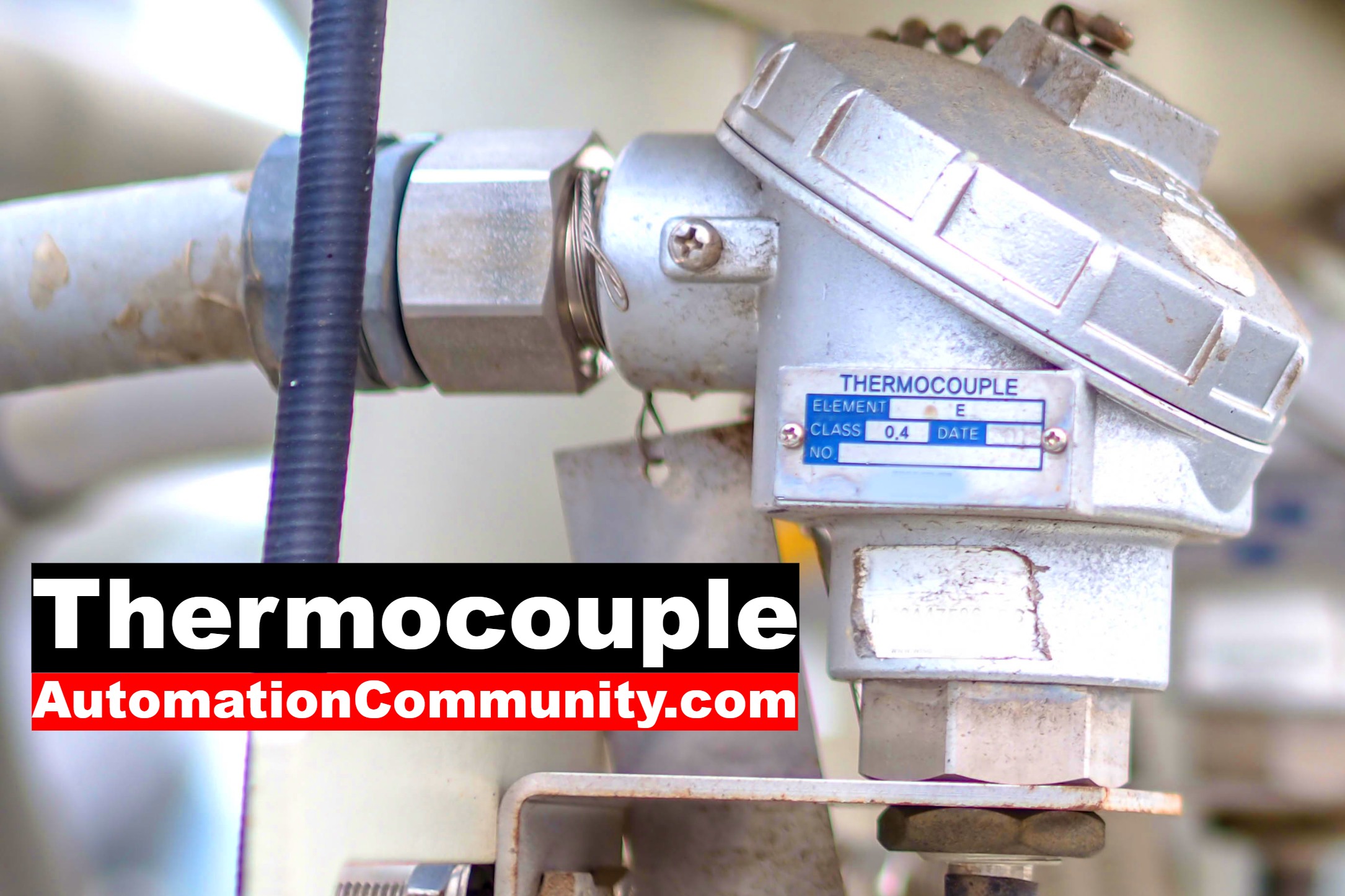

Could you briefly explain what a thermocouple is?

A thermocouple is a type of temperature sensor that works on the principle of the Seebeck effect. It consists of two dissimilar metal wires joined at one end, known as the junction. When the junction experiences a change in temperature, it generates a voltage proportional to that temperature change.

What is the Seebeck effect that forms the basis for thermocouple operation?

The Seebeck effect refers to the phenomenon where a temperature difference between two different metals or semiconductors produces a voltage difference. It is named after the German physicist Thomas Seebeck, who discovered this effect.

How is a thermocouple different from a resistance temperature detector (RTD)?

While both are used to measure temperature, they operate on different principles. A thermocouple uses the Seebeck effect to generate a voltage proportional to the temperature, while an RTD uses the change in electrical resistance of a material with temperature to determine the temperature.

What are some common types of thermocouples?

There are several common types of thermocouples, each designated by a letter, including type K (Chromel-Alumel), type J (Iron-Constantan), type T (Copper-Constantan), type E (Chromel-Constantan), type N (Nicrosil-Nisil), type S (Platinum Rhodium-Platinum), and type B (Platinum Rhodium-Platinum Rhodium).

What are the typical applications of thermocouples?

Thermocouples are used across a wide range of industries for temperature monitoring and control. This includes applications in power generation, oil and gas, food processing, HVAC, automotive, aerospace, and many others.

Why might one choose a type K thermocouple for an application?

Type K thermocouples, made of Chromel and Alumel, are very popular due to their reliability, accuracy, wide temperature range (-200 to +1350°C), and relatively low cost.

How does a cold junction compensation in a thermocouple work?

Cold junction compensation is a method of adjusting the thermocouple voltage to account for the temperature difference at the reference (cold) junction, which is typically at the point where the thermocouple wires connect to the measurement instrument. This is essential for accurate temperature readings.

What is the ‘law of intermediate metals’ in regard to thermocouples?

The ‘law of intermediate metals states that if two dissimilar metals produce a thermoelectric voltage, then the introduction of a third metal to the circuit does not change the overall voltage as long as the junctions of the third metal are at the same temperature.

How can the accuracy of a thermocouple be affected?

Several factors can affect the accuracy of a thermocouple, including the quality of the thermocouple materials, the homogeneity of the thermocouple wires, the temperature of the reference junction, any electromagnetic interference, and the accuracy of the measurement instrument itself.

What are the limitations of using thermocouples?

While thermocouples are versatile, they have certain limitations. For example, they can drift over time, and with repeated temperature cycling, they require a separate reference junction temperature measurement for accuracy, they can be susceptible to corrosion or degradation at high temperatures, and their voltage output is low, requiring careful signal conditioning.

What is the purpose of a thermowell in a thermocouple assembly?

A thermowell is a protective casing that shields a thermocouple from the harsh environment in which it’s placed, such as high-pressure or corrosive substances. It also allows for the removal of the thermocouple without disturbing the process.

What is a ‘noble metal’ thermocouple and when is it used?

A ‘noble metal’ thermocouple refers to types like S, R, and B that use platinum or platinum-rhodium alloy. They are typically used in high-temperature applications (up to 1700°C) and in industries where high accuracy and stability are crucial, like the glass, steel, or semiconductor industry.

What is thermocouple wire color coding and why is it important?

Thermocouple wire color coding is a standardization to identify different types of thermocouples and their polarity. The color coding helps to prevent errors in wiring and connection, and it’s crucial for correct temperature measurement.

What is a ‘grounded junction’ thermocouple and what are its advantages?

In a ‘grounded junction’ thermocouple, the junction of the two thermocouple wires is directly connected (grounded) to the thermocouple sheath. This design provides faster response times and better noise immunity, but it may create a ground loop if the sheath is also grounded at another point.

How are thermocouples calibrated?

Thermocouples are typically calibrated by comparing their output to a known temperature reference, such as an ice bath (0°C) or the triple point of water (0.01°C). The calibration can be used to create a correction table or curve, or to check the conformity to standard thermocouple tables.

What’s a ‘high limit’ thermocouple and where is it used?

A ‘high limit’ thermocouple is designed to withstand and measure extremely high temperatures. It’s typically used in applications like furnaces, kilns, or gas turbine exhaust where the temperature exceeds the range of standard thermocouples.

How can you identify a faulty thermocouple?

A faulty thermocouple may produce readings that are erratic, consistently too high or too low, or out of range for the expected temperature. Electrical tests, like resistance checks or output voltage checks at known temperatures, can be used to confirm the fault.

What are some considerations for thermocouple installation?

When installing a thermocouple, consider factors like the temperature range, the environmental conditions (corrosive, high pressure, etc.), the response time required, the length and routing of the thermocouple wires, and the need for a protective thermowell.

How can thermocouples be protected from corrosion?

Thermocouples can be protected from corrosion by selecting a suitable thermocouple type and sheath material for the environment, by using a protective thermowell, and by maintaining a clean and dry thermocouple assembly.

What is the difference between a ‘grounded junction’ and an ‘ungrounded junction’ thermocouple?

In a ‘grounded junction’ thermocouple, the thermocouple junction is in electrical contact with the sheath, providing a faster response but the potential for ground loops. In an ‘ungrounded junction’ thermocouple, the junction is electrically isolated from the sheath, providing a slower response but better isolation from electrical noise and potential ground loops.

Why do different types of thermocouples have different temperature ranges?

Different types of thermocouples use different combinations of metal alloys for their thermoelectric pairs. These alloy combinations produce different voltages per degree of temperature change and have different characteristics in terms of corrosion resistance, stability, and maximum temperature, leading to different temperature ranges.

What are some common causes of thermocouple failure?

Common causes of thermocouple failure can include corrosion, mechanical damage, degradation from repeated temperature cycling, outgassing or contamination at high temperatures, and electrical overload or short circuits.

Can a thermocouple measure negative temperatures?

Yes, many types of thermocouples can measure negative temperatures. However, the accuracy and range for negative temperatures may be different from the positive temperature range.

What is meant by the ‘cold junction’ in a thermocouple?

The ‘cold junction’, also known as the reference junction, is the end of the thermocouple that is kept at a known, stable temperature. This is typically where the thermocouple wires connect to the measurement instrument. The temperature at the cold junction is needed to calculate the absolute temperature at the hot junction.

How does the length of a thermocouple affect its performance?

The length of a thermocouple can affect its response time, its resistance (which can affect the signal voltage), and the potential for signal loss or noise pickup. However, as long as the measurement instrument can handle the resistance and the signal is properly conditioned, a thermocouple can be quite long.

How do you interpret a thermocouple voltage output?

A thermocouple voltage output is interpreted using the standard tables or equations for that type of thermocouple, which relates the thermocouple voltage to the temperature difference between the hot and cold junctions. The cold junction temperature is then added to get the absolute temperature at the hot junction.

What precautions should be taken when using a thermocouple in a hazardous environment?

When using a thermocouple in a hazardous environment, use a protective thermowell, select a suitable thermocouple and sheath material for the conditions, ensure that any flammable or explosive gases are excluded from the thermocouple assembly, and follow any relevant safety standards or regulations.

How can you check the calibration of a thermocouple?

The calibration of a thermocouple can be checked by measuring the thermocouple output at known, stable temperatures, such as an ice bath or a precision temperature oven, and comparing the measurements to the standard tables or calibration curve for that type of thermocouple.

What are some considerations for selecting a thermocouple type for a specific application?

When selecting a thermocouple type for a specific application, consider the temperature range, the accuracy and stability requirements, the environmental conditions (corrosion, vibration, pressure, etc.), the response time needed, and the compatibility with the measurement instrumentation.

What materials are commonly used to make thermocouples and why?

Different types of thermocouples use different combinations of metal alloys. For example, type K uses Chromel and Alumel, type J uses Iron and Constantan, and type S uses Platinum and Platinum-Rhodium. These materials are chosen for their thermoelectric properties, their temperature range, their stability, and their cost.

What is meant by the ‘Seebeck coefficient’ in relation to thermocouples?

The ‘Seebeck coefficient’ is a measure of the change in the thermoelectric voltage with temperature for a particular material. It is a key factor in determining the temperature sensitivity and range of a thermocouple.

What are some ways to reduce errors when using thermocouples?

To reduce errors when using thermocouples, ensure accurate cold junction compensation, use appropriate signal conditioning and shielding to reduce noise and interference, calibrate the thermocouple and measurement instrument regularly, and protect the thermocouple from damage, contamination, and extreme conditions.

What is an ‘exposed junction’ thermocouple and what are its advantages and disadvantages?

An ‘exposed junction’ thermocouple has the thermocouple junction exposed directly to the medium to be measured, without a protective sheath or thermowell. This provides a fast response time, but the junction may be more susceptible to corrosion, mechanical damage, or contamination.

What are the different ways to connect a thermocouple to a measurement instrument?

A thermocouple can be connected to a measurement instrument by direct soldering, screw terminals, spring-loaded terminals, or special thermocouple connectors. The connection method should ensure good electrical contact and avoid introducing any additional junctions of dissimilar metals.

Can a thermocouple be repaired if it’s damaged?

A damaged thermocouple can sometimes be repaired by trimming back the wires to a good section and re-making the junction, but this depends on the type and extent of the damage, and the repair may affect the accuracy or reliability of the thermocouple.

What is meant by the ‘response time’ of a thermocouple?

The ‘response time’ of a thermocouple is the time it takes for the thermocouple to register a certain percentage (usually 63.2%) of a step change in temperature. It is affected by the mass and construction of the thermocouple, the thermal conductivity of the environment, and the flow rate (for fluids).

What are some common misconceptions about thermocouples?

Some common misconceptions about thermocouples include the idea that they measure absolute temperature directly (they actually measure a temperature difference), that they don’t need any power supply (they generate their own voltage, but the measurement instrument still needs power), and that they can measure any temperature (each type has a specific temperature range and accuracy).

How is a thermocouple junction constructed?

A thermocouple junction is constructed by joining two different thermocouple wires together at one end. This can be done by welding, brazing, or twisting and soldering the wires, depending on the type of thermocouple and the application.

Can a thermocouple be used to measure the temperature of a solid object?

Yes, a thermocouple can be used to measure the temperature of a solid object, either by inserting it into a drilled hole in the object, by pressing it against the surface with good thermal contact, or by embedding it into the object during manufacturing.

How does a dual-element thermocouple work and where is it used?

A dual-element thermocouple has two independent thermocouples in a single probe. It can be used to measure two different points, to provide redundancy, or to detect any gradient or difference in temperature. It’s used in applications where precise temperature control or verification of temperature is required.

What are ‘special limits of error’ (SLE) thermocouples?

‘Special limits of error’ (SLE) thermocouples are manufactured to tighter tolerances than the standard ‘limits of error’ for a particular thermocouple type. This means they provide a higher accuracy but they may also be more expensive.

Can thermocouples be used to measure humidity or pressure?

Thermocouples are primarily designed to measure temperature. While temperature measurements can sometimes be used as part of a system to measure humidity or pressure, a thermocouple itself does not directly measure these quantities.

How does the diameter of a thermocouple wire affect its performance?

The diameter of a thermocouple wire affects its resistance (larger diameter means lower resistance), its mechanical strength and flexibility, and its response time (smaller diameter usually means faster response). The choice of wire diameter depends on the specific application and installation constraints.

How are thermocouples used in a temperature control system?

In a temperature control system, a thermocouple is used as the sensor to measure the current temperature. This measurement is then compared to the desired setpoint temperature, and the difference (error) is used to control a heating or cooling element to reduce the error and maintain the setpoint temperature.

What is ‘thermal shock’ and how can it affect a thermocouple?

‘Thermal shock’ refers to a rapid change in temperature, which can cause materials to expand or contract rapidly and possibly fracture. For a thermocouple, thermal shock can cause mechanical damage, shift the calibration, or cause outgassing or contamination at high temperatures.

What factors can cause a thermocouple to drift over time?

Factors that can cause a thermocouple to drift over time include aging of the thermocouple materials, contamination or corrosion of the thermocouple wires or junction, mechanical stress or vibration, repeated temperature cycling, and extreme temperatures or thermal shock.

What is the maximum length for a thermocouple wire?

The maximum length for a thermocouple wire depends on several factors, including the wire diameter, the type of thermocouple, the temperature range, the allowable voltage drop, and the level of electrical noise or interference. In general, thermocouple wires can be quite long, up to hundreds of feet or even more, but signal conditioning may be needed for long runs.

How can you avoid ground loops when using thermocouples?

To avoid ground loops when using thermocouples, use ungrounded junction thermocouples, avoid grounding the thermocouple sheath at more than one point, and isolate the thermocouple measurement instrument from other grounded equipment. Using differential measurement techniques and proper shielding and grounding of the measurement system can also help.

What is a ‘mineral insulated’ (MI) thermocouple and what are its advantages?

A ‘mineral insulated’ (MI) thermocouple has thermocouple wires embedded in a compacted mineral insulator, usually magnesium oxide, and enclosed in a metal sheath. This provides excellent mechanical strength and durability, good thermal conductivity for fast response, and good electrical insulation.

What is the ‘Curie point’ and how does it relate to thermocouples?

The ‘Curie point’ is the temperature at which a ferromagnetic material becomes paramagnetic. For thermocouples, this is important because the thermoelectric properties of some thermocouple materials, like Iron in a type J thermocouple, change at their Curie point, which limits the maximum temperature for those types.

What is the standard formula for converting thermocouple voltage to temperature?

Conversion from thermocouple voltage to temperature is typically done using tabulated reference values or polynomial equations specific to each type of thermocouple. These are available in standards such as NIST ITS-90 Thermocouple Database. The direct formula may not be straightforward due to the non-linear nature of the thermocouple voltage-temperature relationship.

What is the role of the Nernst equation in thermocouple theory?

The Nernst equation describes the voltage developed by a junction of two different metals – which is the principle by which a thermocouple operates. It’s not commonly used directly in practical thermocouple applications, but it provides the underlying theoretical foundation.

Can you explain the use of the Seebeck coefficient in thermocouple calculations?

The Seebeck coefficient, also known as thermopower, is the ratio of the induced thermoelectric voltage to the temperature difference between the junctions of a thermocouple. This coefficient is unique for each type of thermocouple and is used to convert the measured voltage to the corresponding temperature difference.

What is cold junction compensation and how is it calculated?

Cold junction compensation accounts for the fact that the reference (cold) junction of a thermocouple is not always at 0°C. It’s calculated by measuring the actual temperature of the reference junction and adjusting the measured thermocouple voltage to represent the temperature difference from this actual reference temperature rather than from 0°C.

How do I calculate the temperature when I have a millivolt reading from a thermocouple?

To calculate the temperature from a millivolt reading, you use the specific millivolt-to-temperature conversion chart or polynomial equation for the type of thermocouple you’re using. Add this value to the cold junction temperature if cold junction compensation is not already accounted for.

How can I calculate the output voltage of a thermocouple given a specific temperature difference?

You can calculate the output voltage of a thermocouple given a specific temperature difference using the specific temperature-to-voltage conversion chart or polynomial equation for the type of thermocouple you’re using. Keep in mind that these calculations are based on the reference junction being at 0°C.

Is it possible to convert the voltage reading from one type of thermocouple to the equivalent reading for another type of thermocouple?

Converting directly from the voltage reading of one type of thermocouple to another is not straightforward due to the unique voltage-temperature characteristics of each type. However, you can convert the voltage reading to a temperature using the first thermocouple’s conversion data, and then convert that temperature to the equivalent voltage for the second type of thermocouple.

What are the calculation steps to derive temperature from a thermocouple reading?

First, measure the thermocouple voltage and the actual reference junction temperature. Convert the thermocouple voltage to the equivalent temperature difference from 0°C using the specific voltage-to-temperature conversion data for the thermocouple type. Finally, add the reference junction temperature to this temperature difference to get the absolute temperature at the measuring junction.

Can you explain how the Law of Intermediate Metals applies to thermocouples?

The Law of Intermediate Metals states that if two dissimilar metals produce a thermoelectric voltage, then introducing a third metal into the circuit will not change the voltage as long as the junctions with the third metal are at the same temperature. This principle is used to allow connections and extensions using different metals, without affecting the thermocouple reading.

How can you test a thermocouple to see if it’s working properly?

One simple way to test a thermocouple is to measure the voltage it produces with a multimeter when it’s heated and compare this to the expected voltage for its type and the temperature difference. A significant deviation may indicate a problem. Other testing methods include resistance checks and comparison to a known reference temperature.

How can you troubleshoot a thermocouple that’s giving incorrect readings?

First, verify that the thermocouple is properly installed and that there are no obvious signs of damage or contamination. Check the connections and wiring for continuity and correct polarity. Ensure that the cold junction compensation is accurate. If possible, compare the thermocouple’s reading to a known reference temperature or a reliable second thermometer.

What could cause a thermocouple to fail prematurely?

A thermocouple can fail prematurely due to mechanical damage, corrosion or contamination, overheating beyond its rated limits, or repeated thermal cycling. Incorrect installation or poor electrical connections can also cause problems.

Can you use a standard multimeter to test a thermocouple?

Yes, you can use a standard multimeter that can measure millivolts to test a thermocouple. Connect the multimeter to the thermocouple and apply heat to the sensing junction. The multimeter should read a voltage that corresponds to the temperature difference according to the thermocouple’s voltage-temperature characteristics.

How can you identify the type of thermocouple if it’s not labeled?

If a thermocouple is not labeled, you might identify it by the color of the wires, which are standard for each type in a given country (but can differ between countries). Measuring the voltage it produces for a known temperature difference could also give clues to its type. However, these methods may not be fully reliable.

How can you determine if a thermocouple is grounded or ungrounded?

You can determine if a thermocouple is grounded or ungrounded by checking the continuity between the thermocouple junction and the sheath with a multimeter. If there is continuity, the thermocouple is grounded. If there is no continuity, it’s ungrounded.

What are some common issues that can cause noise or instability in a thermocouple reading?

Common issues that can cause noise or instability in a thermocouple reading include electromagnetic interference (EMI), radio-frequency interference (RFI), ground loops, thermal or mechanical vibrations, rapid temperature fluctuations, or loose or poor-quality electrical connections.

What steps can you take if a thermocouple is not reaching the expected temperature?

If a thermocouple is not reaching the expected temperature, ensure that it’s properly positioned and in good thermal contact with the medium. Check for any heat losses due to conduction, convection, or radiation. Ensure that the heating or cooling element and the control system are working correctly. You could also verify the accuracy of the thermocouple with a known reference temperature.

How can you determine the sheath material of a thermocouple probe?

The sheath material of a thermocouple probe may be identified by its appearance, magnetic properties, or markings. For a definitive identification, you might need information from the manufacturer or a material analysis.

How do you test the insulation resistance of a thermocouple?

The insulation resistance of a thermocouple can be tested with a megohmmeter or “megger”. Connect one lead to the thermocouple wires and the other lead to the sheath, and apply a test voltage. The megohmmeter measures the resistance, which should be high (several megaohms or more) for good insulation.

Can you describe the composition and general uses of a Type K thermocouple?

A Type K thermocouple, also known as Chromel-Alumel, is made from a nickel-chromium alloy (Chromel) and a nickel-aluminum alloy (Alumel). It’s the most common general-purpose thermocouple due to its wide temperature range (-200 to 1250°C), good accuracy, and relatively low cost.

What makes a Type J thermocouple suitable for certain applications?

A Type J thermocouple uses Iron and Constantan (a copper-nickel alloy). It has a more limited temperature range (-40 to 750°C) than some other types, but it’s more stable and accurate at lower temperatures. It’s commonly used in plastics processing and HVAC applications.

What are the characteristics and common uses of a Type T thermocouple?

A Type T thermocouple is made from Copper and Constantan. It has excellent accuracy and stability at low temperatures (-200 to 350°C), making it suitable for low-temperature applications such as cryogenics, ultralow freezers, and environmental monitoring.

Can you describe a Type E thermocouple and its applications?

A Type E thermocouple, made from Chromel and Constantan, provides the highest EMF output per degree of all the thermocouple types, resulting in high accuracy, particularly in the -50 to 500°C range. It’s non-magnetic and often used in laboratory, aerospace, and other precision applications.

Why would one choose to use a Type N thermocouple?

A Type N thermocouple, made from Nicrosil and Nisil (two nickel-based alloys), was designed to be an improved version of the Type K with better stability and resistance to high-temperature oxidation. It’s used in similar applications as the Type K, particularly when a longer service life is desired.

What are the key features of a Type S thermocouple?

A Type S thermocouple, made from Platinum-Rhodium (10%) and Platinum, is highly stable and accurate at high temperatures, up to 1480°C. It’s often used in high-temperature applications such as kilns, gas turbines, and industrial process control, and it’s also used as a standard for calibrating other thermocouples.

What makes a Type B thermocouple unique among thermocouple types?

A Type B thermocouple, made from Platinum-Rhodium (30%) and Platinum-Rhodium (6%), is unique because its EMF-temperature curve has a flat region around 0°C, so it gives nearly the same voltage for any reference temperature in the -50 to 50°C range. It’s used for very high-temperature measurements up to 1700°C.

What are the characteristics and common uses of a Type R thermocouple?

A Type R thermocouple, made from Platinum-Rhodium (13%) and Platinum, is similar to Type S but typically has a higher Rhodium content which provides slightly better performance at high temperatures. It’s used in similar high-temperature and calibration applications as Type S.

How does a Type C thermocouple differ from the other types?

A Type C thermocouple, made from Tungsten-Rhenium (5%) and Tungsten-Rhenium (26%), differs from the other common types in that it can measure much higher temperatures, up to 2300°C. However, it’s more sensitive to atmospheric contamination and has a shorter lifespan. It’s used in very high-temperature applications such as research and development or materials testing.

What are the standard color codes for thermocouple wires?

The standard color codes for thermocouple wires vary by country. For example, in the US, Type K is yellow and red, Type J is white and red, and Type T is blue and red. However, these colors can vary in other countries, so it’s important to refer to the relevant standards or manufacturer’s data.

Can you describe the standard color coding for a Type N thermocouple in the US?

In the United States, according to ANSI standards, a Type N thermocouple uses orange for the positive (Nicrosil) wire and red for the negative (Nisil) wire.

How are European thermocouple wire color codes different from those in the US?

European thermocouple wire color codes, according to IEC standards, are different from those in the US. For example, a Type K thermocouple in Europe uses green for the positive (Chromel) wire and white for the negative (Alumel) wire, whereas in the US, it’s yellow and red respectively.

What is the importance of polarity in thermocouple wiring?

Polarity is crucial in thermocouple wiring because thermocouples rely on the Seebeck effect, which is direction sensitive. Reversing the polarity will reverse the direction of the current flow, causing the thermocouple to read in the opposite direction.

Can you use any type of wire to extend a thermocouple circuit?

Ideally, a thermocouple circuit should be extended using an extension wire of the same thermocouple type to ensure accurate temperature measurement. If this is not feasible, compensating cables with similar thermoelectric properties can be used for short extensions, but this may introduce some errors.

What considerations should be taken into account when selecting a thermocouple connector?

When selecting a thermocouple connector, consider the type of thermocouple it will be used with, as different types require different connectors. Also consider the environmental conditions such as temperature, humidity, and potential exposure to corrosive substances. The connector should provide a good electrical connection and should be robust enough for the intended use.

Why might one prefer thermocouple wire insulation made from PTFE?

PTFE (polytetrafluoroethylene) insulation is resistant to high temperatures, chemicals, and moisture. It also has excellent electrical insulation properties. These characteristics make PTFE a good choice for thermocouple wire insulation in demanding applications.

What are the color codes for a Type E thermocouple in Australia?

In Australia, following the Australian AS 60584.1-2013 standard, a Type E thermocouple uses purple for the positive (Chromel) wire and red for the negative (Constantan) wire.

How do you connect multiple thermocouples to a single measurement device?

To connect multiple thermocouples to a single measurement device, each thermocouple must have its own input channel. The device must be capable of reading multiple channels, either simultaneously or sequentially. It’s important to maintain proper polarity and to avoid any interference between channels.

Can you describe the color coding for a Type B thermocouple in Japan?

In Japan, following the JIS C 1610-1999 standard, a Type B thermocouple uses gray for the positive (Platinum-Rhodium 30%) wire and white for the negative (Platinum-Rhodium 6%) wire.

Why should you avoid unnecessary bends in thermocouple wire?

Unnecessary bends in thermocouple wire should be avoided because they can lead to mechanical stress and potential breakage of the wire. Repeated bending can also cause work hardening and brittleness in some thermocouple materials, further increasing the risk

What is the ANSI/ASTM E230 standard in relation to thermocouples?

The ANSI/ASTM E230 standard, also known as “Standard Specification and Temperature-Electromotive Force (EMF) Tables for Standardized Thermocouples”, provides the technical specifications, color codes, and reference tables for thermocouples, and it’s widely recognized and used in the United States.

Can you explain the role of the IEC 60584 standard for thermocouples?

The IEC 60584 standard is an international standard that defines the thermoelectric voltage of a thermocouple as a function of the thermocouple temperature, and it also provides the color coding for thermocouple wires in countries following IEC standards. It ensures consistent performance and interchangeability of thermocouples globally.

What does the NIST ITS-90 Thermocouple Database provide?

The NIST (National Institute of Standards and Technology) ITS-90 Thermocouple Database provides reference functions and tables for the eight letter-designated types of thermocouples. These reference functions are based on the International Temperature Scale of 1990 (ITS-90). The database can be used for accurate temperature calculation and calibration.

What is the purpose of the ASTM E220 standard?

The ASTM E220 standard, “Standard Test Method for Calibration of Thermocouples by Comparison Techniques”, provides guidelines for calibrating thermocouples to ensure accurate and consistent measurements. This calibration is done by comparing the thermocouple’s readings with the known temperature of a calibration furnace or other reference.

What does the JIS C 1602 standard cover in Japan?

The JIS (Japanese Industrial Standards) C 1602 standard covers thermocouples in Japan. It provides specifications for their construction, tolerances, identification, and testing, similar to the ANSI/ASTM E230 standard in the US or the IEC 60584 standard internationally.

How does the IEC 61515 standard apply to thermocouples?

The IEC 61515 standard is an international standard for industrial process control systems and specifies general requirements and directions for the installation and use of thermocouples.

What is the role of the ANSI MC 96.1 standard?

The ANSI MC 96.1 standard provides specifications for the performance of industrial-use thermocouples, including limits of error, and it’s widely followed in the US industry.

Can you explain what the DIN EN 60584 standard stipulates?

The DIN EN 60584 standard, followed in Germany and many European countries, is equivalent to the IEC 60584 standard and provides similar specifications and temperature-electromotive force tables for standardized thermocouples.

What is the significance of the GOST R 8.585-2001 standard for thermocouples in Russia?

The GOST R 8.585-2001 is the Russian national standard for thermocouples. It specifies the types, basic parameters, technical requirements, test methods, and ordering information for thermocouples.

What does the NACE MR0175/ISO 15156 standard say about the use of thermocouples in sour service applications?

The NACE MR0175/ISO 15156 standard, “Petroleum and natural gas industries – Materials for use in H2S-containing environments in oil and gas production”, includes requirements for thermocouples used in sour service

What could cause a thermocouple to read temperatures that are too high?

A thermocouple might read too high if it is exposed to electromagnetic interference if the measurement junction is not in good thermal contact with the object being measured, or if there’s a short circuit in the thermocouple wires or connections.

What would cause a thermocouple to produce a signal even when it’s not heated?

This could be due to a phenomenon known as “thermal shunting”, where heat is being conducted along the thermocouple wires themselves from a warmer area to the junction. It could also be due to ambient electromagnetic noise being picked up by the thermocouple.

How can “cold junction compensation” errors affect thermocouple readings?

If the cold junction (reference junction) temperature is not accurately measured or compensated, this can introduce errors in the thermocouple readings. This is because the thermoelectric voltage produced by the thermocouple depends on the difference between the hot junction and cold junction temperatures.

What could cause a slow response time in a thermocouple?

A slow response time in a thermocouple can be caused by a large probe size, poor thermal contact with the object being measured, or the presence of a thermal well or sheath that slows down heat transfer.

What are some potential effects of mechanical stress on a thermocouple?

Mechanical stress can cause physical damage to the thermocouple wires, which can lead to open circuits or changes in the thermoelectric characteristics of the wires. It can also cause work hardening and brittleness in the wires, increasing the risk of breakage.

How can moisture affect a thermocouple?

Moisture can cause corrosion or oxidation of the thermocouple wires, especially at high temperatures. This can change the thermoelectric properties of the wires, leading to inaccurate readings. Moisture can also cause short circuits if it penetrates the insulation.

What could cause a “drift” in thermocouple readings over time?

A drift in thermocouple readings can be caused by changes in the thermoelectric properties of the wires due to aging, high-temperature exposure, or chemical attack. Other potential causes include instability in the measurement electronics and changes in the thermal environment of the cold junction.

What are some potential causes of thermocouple failure?

Thermocouple failure can be caused by various factors, such as physical damage to the wires or connections, corrosion or oxidation of the wires, prolonged exposure to high temperatures, thermal or mechanical shock, or degradation of the insulation.

How can you determine if a thermocouple is open-circuited?

An open-circuited thermocouple can be identified by a sudden drop in the output signal to zero or to the ambient temperature value. This can be confirmed with an ohmmeter by checking for continuity in the thermocouple circuit.

How can you troubleshoot a thermocouple that’s giving inconsistent readings?

Troubleshooting a thermocouple with inconsistent readings can involve checking for loose or corroded connections, verifying the correct polarity of the connections, checking for electromagnetic interference, and inspecting the wires for physical damage or insulation breakdown. It might also involve testing the thermocouple with a known temperature source or a different measurement device.

Read Next:

Comments

1

great information, thank you.