Venturi Flow Meter and Flow Element – Instrumentation Basics

The Venturi Flow Meter and Flow Element are essential devices used in the measurement of fluid flow rates in various industrial applications. The Venturi flow meter, named after its inventor Giovanni Battista Venturi, operates on the principle of fluid flow through a converging and diverging section, resulting in a pressure drop that is directly proportional to the flow rate. The flow element, on the other hand, is a generic term that encompasses different types of devices, including orifice plates, flow nozzles, and Venturi tubes, which are used to create a measurable pressure drop for flow rate calculation. Understanding the principles, operation, and applications of these flow measurement devices is crucial for engineers and professionals involved in process control and instrumentation.

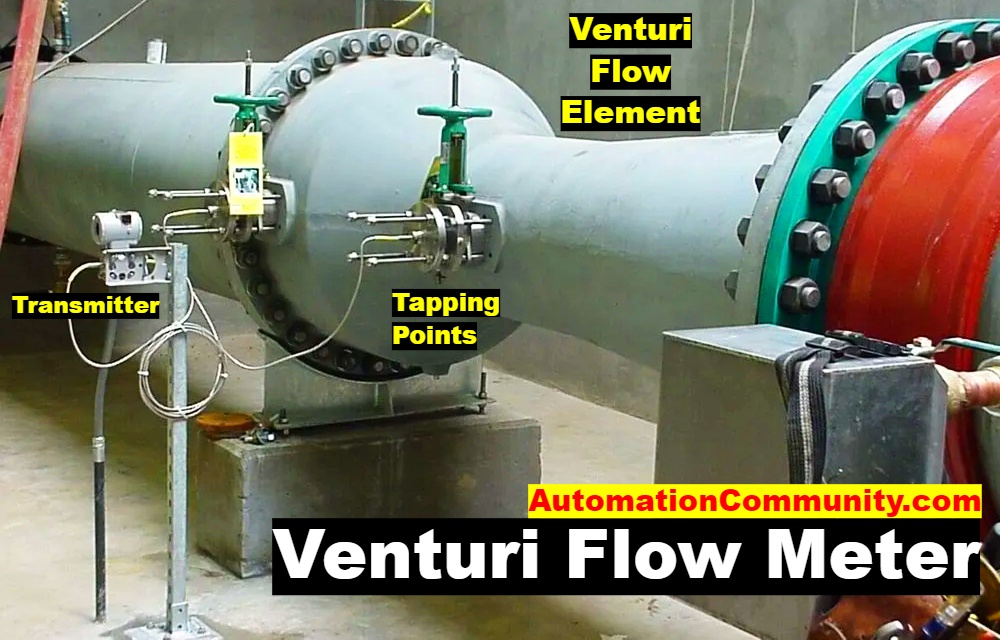

Venturi Flow Meter

Uncover the workings of Venturi Flow Meters and Flow Elements with our comprehensive Questions and Answers guide. Learn about the operating principles, advantages, limitations, and installation considerations for these crucial flow measurement devices.

What is a Venturi flow element?

A Venturi flow element is a device used for measuring the flow rate of a fluid within a pipe. It consists of a short tube with a constricted throat that increases the velocity and decreases the pressure of the fluid passing through it, which can be used to determine the flow rate.

How does a Venturi flow meter work?

The Venturi flow meter works on the principle of the Venturi effect. As fluid enters the constricted area of the meter, it accelerates, causing a drop in pressure. By measuring the differential pressure before and after the constriction, the flow rate can be determined.

What are the advantages of using a Venturi flow meter?

Venturi flow meters are highly accurate and reliable, with low energy loss. They can handle large flow rates and are suitable for use with dirty or particulate-laden fluids. They also require less maintenance compared to other types of flow meters.

Are there any disadvantages to using a Venturi flow meter?

While Venturi flow meters offer many advantages, they can be more expensive than other types of flow meters and may require a significant amount of straight pipe run for accurate measurement. Additionally, they might not be suitable for very low flow rates.

What applications are Venturi flow meters suitable for?

Venturi flow meters are versatile and can be used in a wide range of applications including water supply systems, wastewater treatment, chemical processing, oil and gas industries, and power generation.

What materials are used in the construction of Venturi flow meters?

Venturi flow meters can be made from a variety of materials depending on the application, including stainless steel, carbon steel, PVC, and others. The material is chosen based on the type of fluid to be measured and the operating conditions.

How is the flow rate calculated using a Venturi flow meter?

The flow rate in a Venturi flow meter is calculated using the principle of conservation of energy. The differential pressure measured across the Venturi is proportional to the square of the flow rate. Using this relationship, and knowing the geometrical properties of the Venturi, the flow rate can be calculated.

Can Venturi flow meters measure the flow rate of gases?

Yes, Venturi flow meters can be used to measure the flow rate of gases. However, the gas density must be taken into account, and the meter must be calibrated for the specific gas being measured.

What is the range of flow rates that can be measured with a Venturi flow meter?

Venturi flow meters can measure a wide range of flow rates, from very low to very high, depending on the design of the meter. However, they are most accurate in the middle to high range of their capacity.

What factors affect the accuracy of a Venturi flow meter?

Several factors can affect the accuracy of a Venturi flow meter, including the condition of the meter, the fluid properties, the accuracy of the differential pressure measurement, and the installation conditions.

What is the pressure recovery characteristic of a Venturi flow meter?

Pressure recovery is a feature of Venturi flow meters wherein after the fluid passes the constriction point, the velocity of the fluid decreases, and pressure is regained. This pressure recovery is typically better in Venturi flow meters compared to other differential pressure devices, reducing the total pressure loss in the system.

How does temperature affect the measurement of a Venturi flow meter?

Changes in temperature can affect the density of the fluid, which in turn affects the flow rate calculation. For accurate measurements, temperature compensation may be required in some applications.

What is the effect of viscosity on Venturi flow meter measurements?

Venturi flow meters are typically used for low to medium-viscosity fluids. High-viscosity fluids can lead to an increase in pressure loss and potentially inaccurate measurements.

What maintenance is required for a Venturi flow meter?

Venturi flow meters typically require less maintenance compared to other flow meters as they have no moving parts and the design is less prone to wear and tear. However, regular inspections to ensure there is no damage or blockages are recommended.

Can Venturi flow meters handle multi-phase flows?

Venturi flow meters are best suited for single-phase flows. Multi-phase flows, such as oil and gas mixtures, can make the flow measurements more complex and less accurate.

How does a Venturi flow meter handle turbulent flow?

The design of a Venturi flow meter naturally induces a turbulent flow condition at the throat, which is beneficial as it helps to ensure a stable and repeatable pressure differential.

Can Venturi flow meters be used for bidirectional flow measurement?

Typically, Venturi flow meters are designed for unidirectional flow measurement. For bidirectional flow measurement, two meters may be installed back to back.

What are the upstream and downstream piping requirements for a Venturi flow meter?

For accurate measurement, Venturi flow meters typically require a straight run of pipe upstream and downstream of the meter. The exact requirements can depend on the specific design of the meter.

How does Reynolds number affect Venturi flow meter measurement?

The Reynolds number is a measure of flow regime (laminar, transitional, or turbulent). Venturi flow meters typically operate in the turbulent flow regime where the flow rate is proportional to the square root of the pressure drop.

Can a Venturi flow meter measure flow in a partially filled pipe?

No, Venturi flow meters require a full pipe to accurately measure flow. If the pipe is not completely filled, the meter will read low because the velocity at the throat will not accurately represent the total flow.

What type of output signal is typically provided by a Venturi flow meter?

Venturi flow meters typically provide a differential pressure output which can be converted to an electrical signal (like 4-20mA) for processing and display.

How does the shape of the Venturi tube affect its performance?

The smooth inward and outward curves of a Venturi tube allow for efficient flow with minimal energy loss, making it an effective tool for flow measurement in many different types of applications.

Can Venturi flow meters handle slurries and particulate matter in the fluid?

Yes, due to the absence of moving parts and obstruction-less design, Venturi flow meters can handle fluids with particulates and slurries without significant wear and tear.

Are Venturi flow meters affected by installation orientation?

The installation orientation is generally not critical for Venturi flow meters. However, care should be taken to ensure the pipe is full, especially for liquid applications. For gas measurement, vertical upward flow or horizontal installations are the most common.

Are Venturi flow meters sensitive to vibration?

In general, Venturi flow meters are not highly sensitive to vibration. Their simple, robust design with no moving parts contributes to their resistance to these types of environmental factors.

Can Venturi flow meters be used in high-pressure applications?

Yes, Venturi flow meters can be used in high-pressure applications. The design of the Venturi meter allows it to withstand high pressures.

What is the accuracy of a Venturi flow meter?

The accuracy of a Venturi flow meter is typically within ±1% of full scale.

What maintenance is required for a Venturi flow meter?

Venturi flow meters require minimal maintenance due to their no-moving-parts design. However, regular inspections for potential build-up or erosion, and occasional calibration checks, are recommended to ensure optimal operation.

Is a Venturi flow meter sensitive to changes in fluid viscosity?

Venturi flow meters are not highly sensitive to changes in fluid viscosity. However, if the viscosity change is significant, it can affect the flow profile and potentially impact accuracy.

What is the recovery factor in a Venturi flow meter?

The recovery factor of a Venturi flow meter relates to the amount of pressure that is recovered as the fluid exits the constricted area of the meter.

How does a Venturi flow meter handle suspended solids or debris in the flow?

Venturi flow meters, due to their construction, can handle moderate amounts of suspended solids or debris without much impact on their measurement accuracy. However, excessive amounts can lead to wear and tear, and eventually degradation in performance.

Can Venturi flow meters handle corrosive fluids?

Yes, Venturi flow meters can handle corrosive fluids provided they are constructed from materials resistant to the particular corrosive substance.

What are the installation requirements for a Venturi flow meter?

Installation requirements for a Venturi flow meter typically include a sufficient straight run of pipe upstream and downstream of the meter, and orientation should be considered in relation to gravity and flow direction.

How can we calculate the flow rate using a Venturi flow meter?

The flow rate through a Venturi flow meter can be calculated using Bernoulli’s equation, which relates the pressure, velocity, and elevation of points along a streamline.

Are Venturi flow meters suitable for low-flow applications?

Venturi flow meters are generally used for medium to high-flow applications. However, smaller venturi meters can be used for lower-flow applications.

What parameters can affect the accuracy of a Venturi flow meter?

Factors such as fluid temperature, pressure, viscosity, the presence of solids, and the quality of the upstream and downstream flow profiles can affect the accuracy of a Venturi flow meter.

Read Next: