Advantages and Disadvantages of PLC

In this article, you will learn the advantages and disadvantages of the programmable logic controller (PLC).

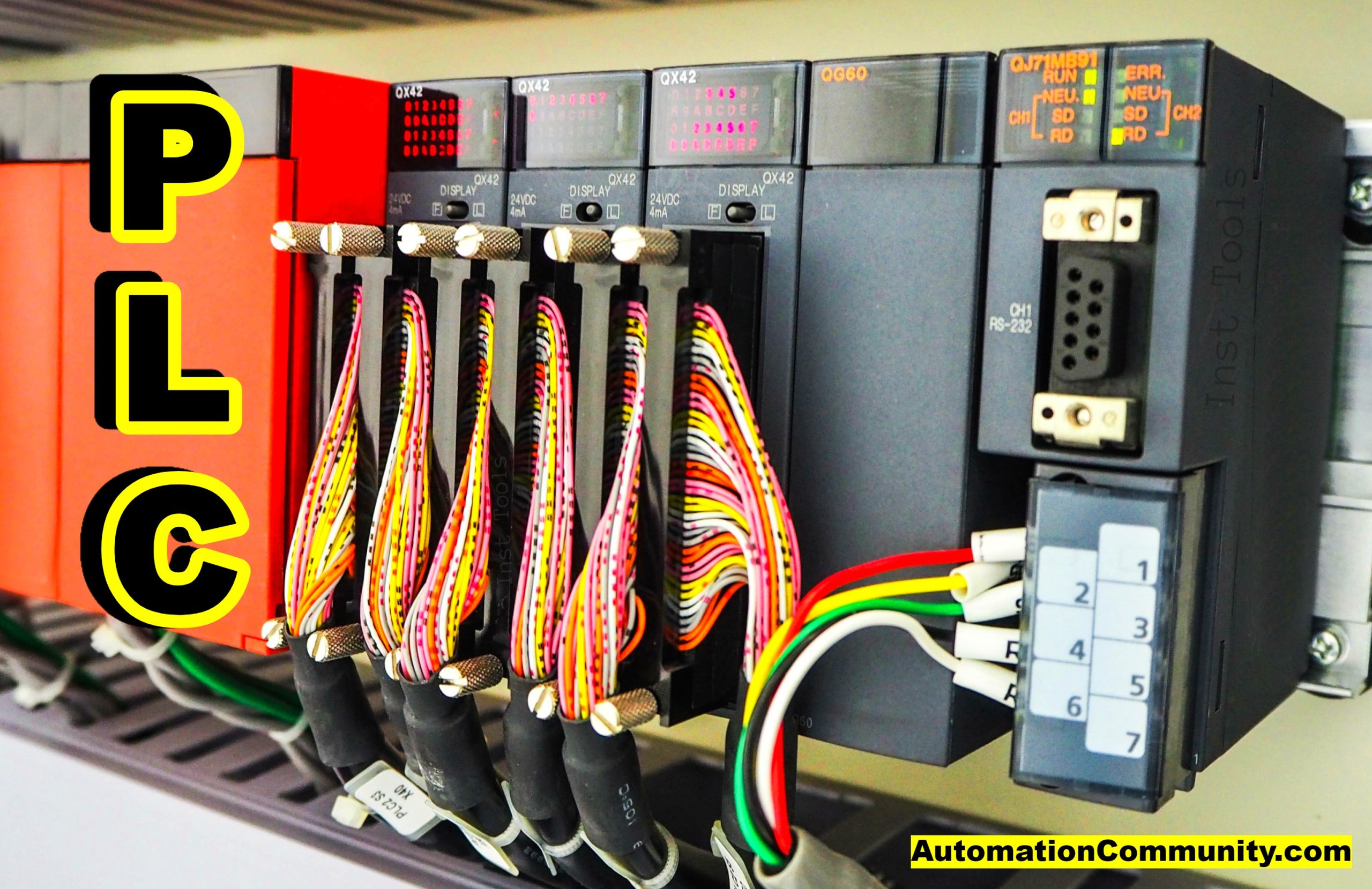

Programmable logic controllers (PLC) are used to automate a wide range of processes and systems, including assembly lines, conveyor belts, and other types of industrial machinery. PLCs are designed to be rugged and reliable, and they can operate in harsh industrial environments.

PLCs are programmed using a specialized programming language, and they can be programmed to perform a wide range of tasks, including controlling motors, relays, and other types of electrical and mechanical devices.

Advantages of PLC

There are several advantages to using programmable logic controllers (PLCs) in industrial control systems:

- Reliability: PLCs are designed to be rugged and reliable, and they can operate in harsh industrial environments. They are less likely to fail than other types of control systems, and they can be programmed to perform a wide range of tasks.

- Flexibility: PLCs can be programmed to perform a wide range of tasks, and they can be easily reprogrammed to perform new tasks as needed. This makes them very flexible and adaptable to changing conditions and requirements.

- Ease of use: PLCs are relatively easy to use, especially when compared to other types of industrial control systems. They can be programmed using a simple, specialized programming language, and they often come with user-friendly software that makes it easy to program and troubleshoot them.

- Cost-effectiveness: PLCs are generally more cost-effective than other types of industrial control systems, especially when the cost of installation, maintenance, and repair is considered.

- Safety: PLCs can be programmed to include safety features that help to protect workers and equipment. For example, they can be programmed to shut down a process if certain conditions are met, such as if a machine is overheating or if there is a risk of a collision.

Disadvantages of PLC

There are also some disadvantages to using programmable logic controllers (PLCs) in industrial control systems:

- Complexity: PLCs can be complex to program and maintain, especially for those who are not familiar with the specialized programming language that is used to program them. This can be a barrier to entry for those who want to use PLCs, and it may require additional training and resources.

- Limited processing power: PLCs are not as powerful as some other types of systems like DCS, and they may not be able to handle complex tasks or large amounts of data.

- Limited expandability: PLCs are designed for specific tasks and processes, and they may not be able to be easily expanded or modified to perform new tasks.

- Cost: While PLCs are generally more cost-effective than other types of industrial control systems, they can still be expensive to purchase and maintain.

- Dependence on programming: PLCs are programmed to perform specific tasks, and if the program is not written correctly, the PLC may not function properly. This can lead to errors and downtime, which can be costly for businesses.

Read Next: