Automation Community Competition Rules

Automation Community Competition Rules. The technical contest for electrical, electronics, instrumentation, and automation engineers.

Read post

Automation Community Services

Check it out!

Talk to a Specialist

We design, integrate, and support industrial automation, with training, consulting, lead generation, and advertising.

Design

Engineering

Debugging

Your Trusted Automation Solution Partner Across All Platforms

Connect every part of your business with integrations that will simplify your workflow.

Developing, modifying, and optimizing PLC programs for safe and reliable control.

Integrating PLCs with instruments, drives, HMIs, and third-party devices.

Validating logic, checking I/O, and supporting safe system startup and online support.

Analyzing runtime issues, sequence failures, and unexpected PLC behavior.

Upgrading existing PLC systems to improve performance and maintainability.

Designing and correcting operator screens for clarity and reliable operation.

Configuring and troubleshooting PLC communication with field and control devices.

Root-cause analysis of recurring automation and control system failures.

Updating logic descriptions, I/O lists, and control documentation.

Training

Learn Automation from Industry Experts

Understand the reasons behind using 4–20 mA in PLC automation and instrumentation systems.

Learn Siemens LOGO! PLC programming with detailed fundamentals with hardware kit.

Beginner Schneider PLC training using EcoStruxure Machine Expert with 75+ practical videos.

Learn Omron PLC programming for students with CX-Programmer basics and practical examples.

Allen-Bradley PLC programming course with clear explanations with practice problems and solutions.

Online Siemens TIA Portal PLC course covering fundamentals and real applications and exercises.

Solutions

Integrated automation services built to manage projects from design, engineering, and execution.

Develop new PLC programs and structured logic aligned with process requirements.

Identifying and correcting PLC logic faults affecting your plant operations and machines healthiness.

Support SCADA architecture, tag mapping, configuration, monitoring, diagnostics, and system health.

Improve system reliability through logic cleanup, tuning, documentation, and support.

Provide fast PLC assistance during breakdowns and production-critical situations.

Connecting PLCs with drives, analyzers, meters, instruments, and third-party systems.

We specialize in a wide variety of industrial automation and control systems. Our core expertise covers programming and troubleshooting for major PLC brands such as Siemens, Allen-Bradley/Rockwell, Schneider Electric, Omron, and Mitsubishi. We also provide comprehensive support for HMI design, SCADA systems (including WinCC, InTouch, and FactoryTalk), VFD integration, and field instrumentation to ensure your machine operations are safe, reliable, and efficient.

Our remote support process is designed for efficiency and is primarily managed through our secure email ticket system. It begins when you submit a support ticket detailing your specific requirements. Our team reviews your scope and suggests the most relevant pricing plan or a custom quote tailored to your needs. Once the payment is processed, our engineers immediately begin work on your project, keeping you informed with regular progress updates via email until the task is successfully completed.

Yes, absolutely. We bridge the gap between traditional plant-floor automation and modern digital systems by supporting a comprehensive range of integration protocols. Our expertise includes standard industrial communication via OPC UA/DA and Modbus TCP/RTU, as well as direct data logging to SQL databases (MySQL, MSSQL) for reporting and MES connectivity. We also specialize in IIoT and Cloud integrations, utilizing MQTT to securely connect your PLCs to platforms like AWS or Azure, enabling real-time remote monitoring, edge computing, and smart data analytics for your entire operation.

Our standard services are calculated on an hourly basis—please refer to our Pricing Page for current rates. However, since every project is unique, we highly recommend contacting us first. We will review your specific requirements and suggest the best standard plan or a custom package tailored exactly to your scope of work.

Yes. Our team consists of veteran automation engineers, each with over 15+ years of hands-on experience in the field. We are not just generalists; our experts possess deep knowledge across major platforms like Siemens, Allen-Bradley, and Schneider Electric, ensuring your system is handled by a true professional.

Automation Community Competition Rules. The technical contest for electrical, electronics, instrumentation, and automation engineers.

Read post

Siemens industrial automation has a vast range of products such as PLC, HMI, SCADA, VFD, etc

Read post

This article is about the introduction to the Internet of Things, the Needs and working of

Read post

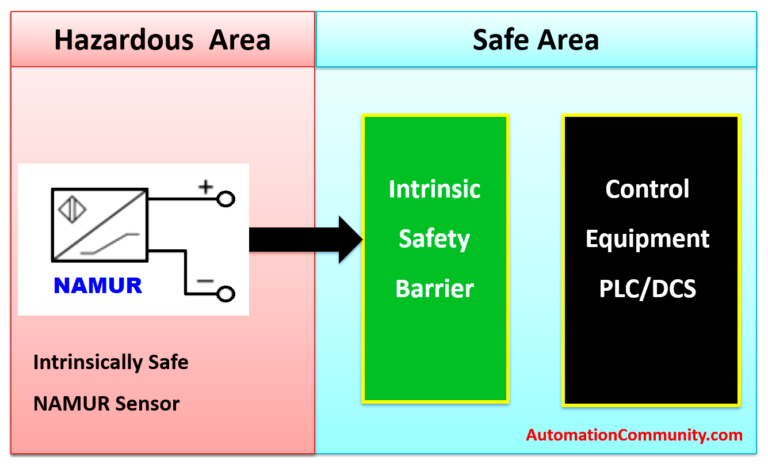

A NAMUR sensor is a 2 wire proximity sensor that was developed to ensure safety in

Read postSolving automation challenges with practical expertise.

Let’s Talk Automation

We design, integrate, & support industrial automation, with training, consulting, lead generation, and advertising.

Resources